25 - Special Table Saw Issue, страница 26

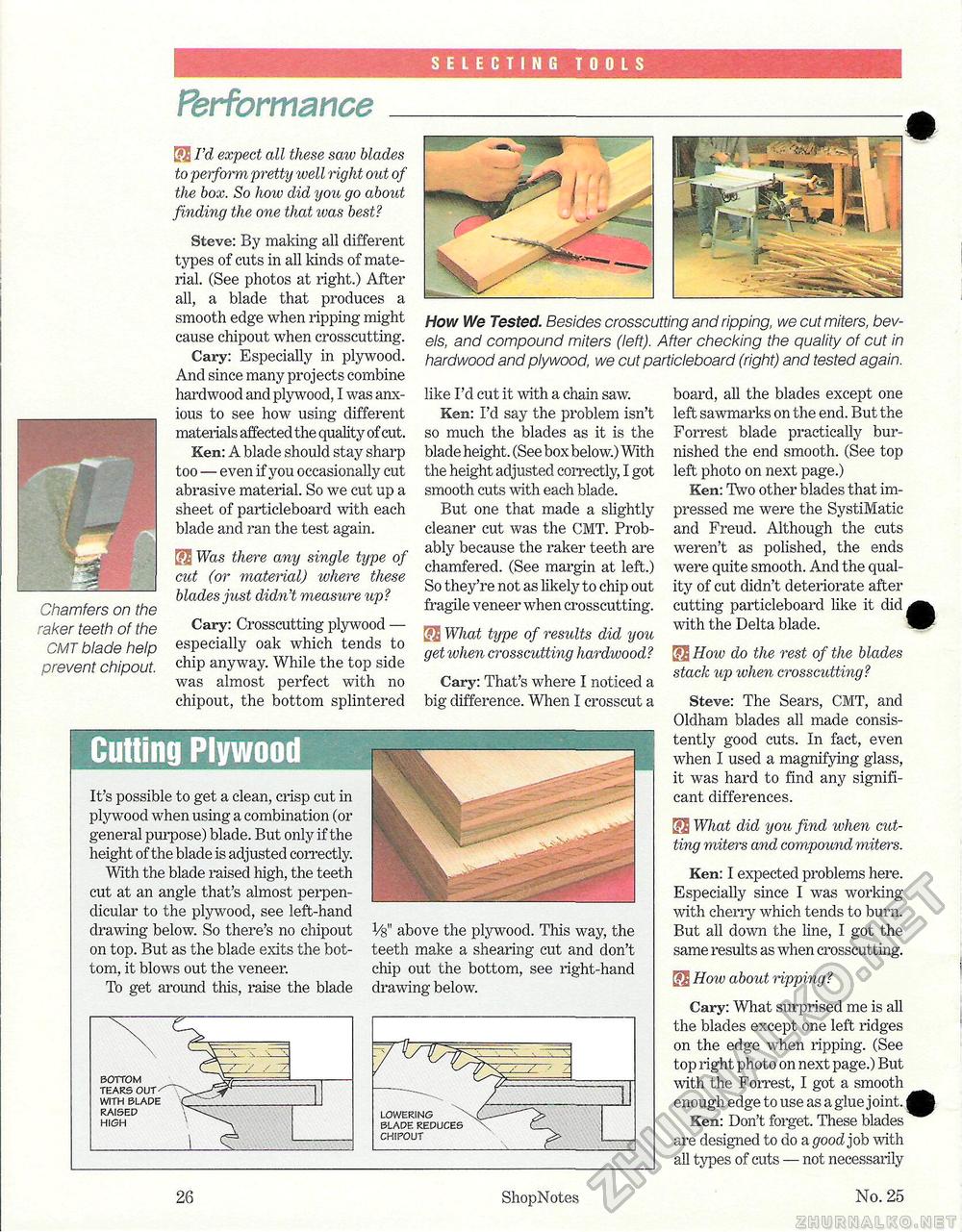

SELECTING TOOLS m ' f 11 Wm SIH'? • stsmger ' 0 Chamfers on the raker teeth of the CMT blade help prevent chipout. Performance I'd expect all these saw blades to perform pretty well right out of the box. So how did you go about finding the one that was best? Steve: By making all different types of cuts in all kinds of material. (See photos at right.) After all, a blade that produces a smooth edge when ripping might cause chipout when crosscutting. Gary: Especially in plywood. And since many projects combine hardwood and plywood, I was anxious to see how using different materials affected the quality of cut. Ken: A blade should stay sharp too — even if you occasionally cut abrasive material. So we cut up a sheet of particleboard with each blade and ran the test again. gj Was there any single type of cut (or material) where these blades just didn't measure up? Gary: Crosscutting plywood — especially oak which tends to chip anyway. While the top side was almost perfect with no chipout, the bottom splintered Cutting Plywood It's possible to get a clean, crisp cut in plywood when using a combination (or general purpose) blade. But only if the height of the blade is adjusted correctly. With the blade raised high, the teeth cut at an angle that's almost perpendicular to the plywood, see left-hand drawing below. So there's no chipout on top. But as the blade exits the bottom, it blows out the veneer. To get around this, raise the blade How We Tested. Besides crosscutting and ripping, we cut miters, bevels, and compound miters (left). After checking the quality of cut in hardwood and plywood, we cut particleboard (right) and tested again. like I'd cut it with a chain saw. Ken: I'd say the problem isn't so much the blades as it is the blade height. (See box below.) With the height adjusted correctly, I got smooth cuts with each blade. But one that made a slightly cleaner cut was the CMT. Probably because the raker teeth are chamfered. (See margin at left.) So they're not as likely to chip out fragile veneer when crosscutting. [H What type of results did you get when crosscutting hardwood? Gary: That's where I noticed a big difference. When I crosscut a Vg" above the plywood. This way, the teeth make a shearing cut and don't chip out the bottom, see right-hand drawing below. board, all the blades except one left sawmarks on the end. But the Forrest blade practically burnished the end smooth. (See top left photo on next page.) Ken: Two other blades that impressed me were the SystiMatic and Freud. Although the cuts weren't as polished, the ends were quite smooth. And the quality of cut didn't deteriorate after cutting particleboard like it did | with the Delta blade. How do the rest of the blades stack up when crosscutting? Steve: The Sears, CMT, and Oldham blades all made consistently good cuts. In fact, even when I used a magnifying glass, it was hard to find any significant differences. What did you find when cutting miters and compound miters. Ken: I expected problems here. Especially since I was working with cherry which tends to burn. But all clown the line, I got the same results as when crosscutting. oio about ripping? Gary: What surprised me is all the blades except one left ridges on the edge when ripping. (See top right photo on next page.) But with the Forrest, I got a smooth enough edge to use as a glue joint. \ Ken: Don't forget. These blades are designed to do a good job with all types of cuts — not necessarily BOTTOM TEARS WITH BLADE RAISED HIGH LOWERING BLADE REDUCES CHIPOUT 26 ShopNotes No. 25 |