38 - Ring Boxes, страница 29

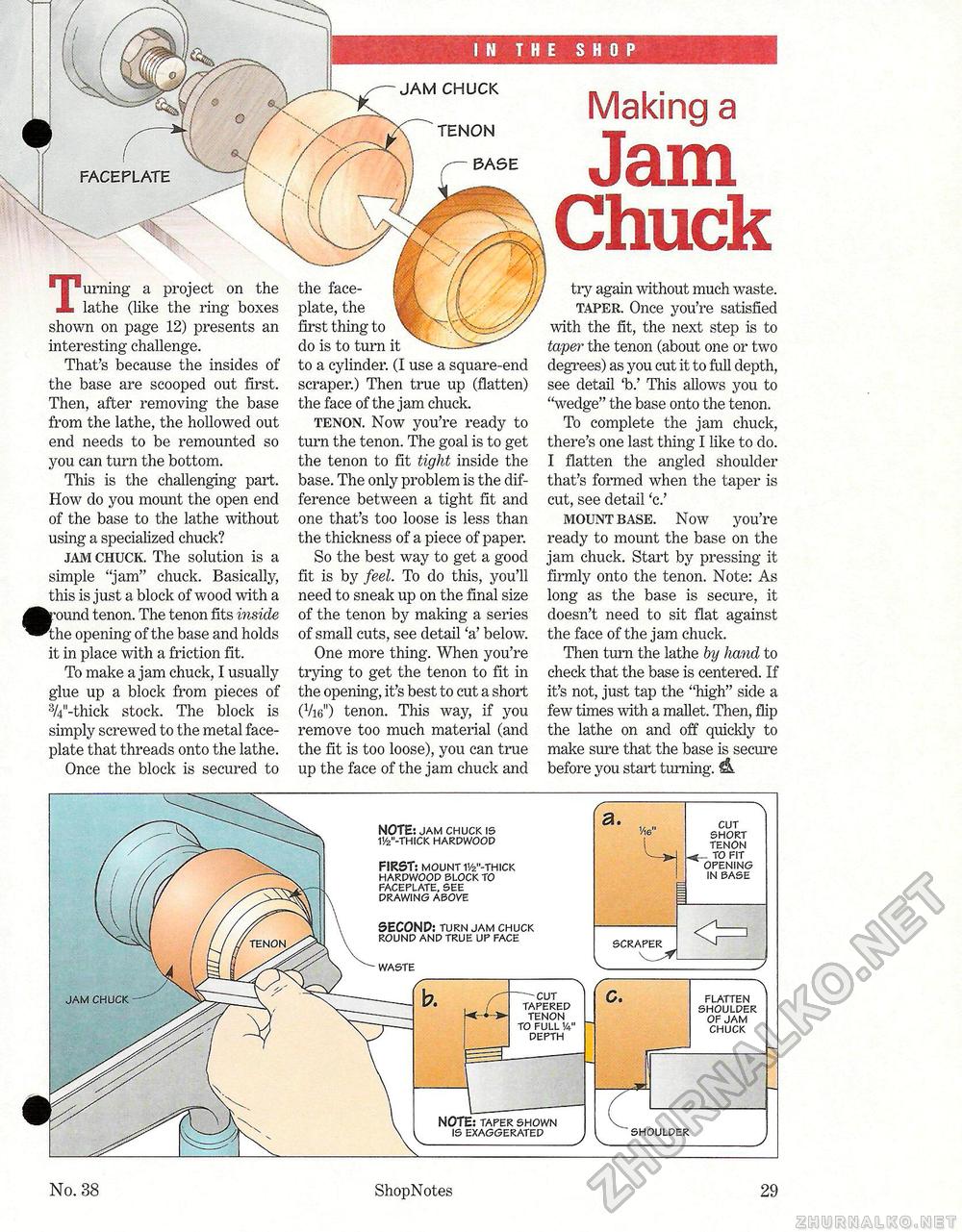

Turning a project on the lathe (like the ring boxes shown on page 12) presents an interesting challenge. That's because the insicles of the base are scooped out first. Then, after removing the base from the lathe, the hollowed out end needs to be remounted so you can turn the bottom. This is the challenging part. How do you mount the open end of the base to the lathe without using a specialized chuck? jam chuck. The solution is a simple "jam" chuck. Basically, this is just a block of wood with a •round tenon. The tenon fits inside the opening of the base and holds it in place with a friction fit. To make a jam chuck, I usually glue up a block from pieces of 'V-thick stock. The block is simply screwed to the metal faceplate that threads onto the lathe. Once the block is secured to the faceplate, the first thing to do is to turn it to a cylinder. (I use a square-end scraper.) Then true up (flatten) the face of the jam chuck. tenon. Now you're ready to turn the tenon. The goal is to get the tenon to fit tight inside the base. The only problem is the difference between a tight fit and one that's too loose is less than the thickness of a piece of paper. So the best way to get a good fit is by feel. To do this, you'll need to sneak up on the final size of the tenon by making a series of small cuts, see detail 'a' below. One more thing. When you're trying to get the tenon to fit in the opening, it's best to cut a short (V1611) tenon. This way, if you remove too much material (and the fit is too loose), you can true up the face of the jam chuck and Making a Jam Chuck try again without much waste. taper. Once you're satisfied with the fit, the next step is to taper the tenon (about one or two degrees) as you cut it to full depth, see detail 'b.' This allows you to "wedge" the base onto the tenon. To complete the jam chuck, there's one last thing I like to do. I flatten the angled shoulder that's formed when the taper is cut, see detail 'c.' mount base. Now you're ready to mount the base on the jam chuck. Start by pressing it firmly onto the tenon. Note: As long as the base is secure, it doesn't need to sit flat against the face of the jam chuck. Then turn the lathe by hand to check that the base is centered. If it's not, just tap the "high" side a few times with a mallet. Then, flip the lathe on and off quickly to make sure that the base is secure before you start turning. A JAM CHUCK TENON £ASE scraper V ^ cut short tenon _ to fit opening in base flatten shoulder of jam chuck NOTE: jam chuck is 1'/2"-thick hardwood FIRST: mount 1V2"-thick hardwood block to faceplate, see drawing above SECOND: turn jam chuck round and true up face jam chuck cut tapered tenon to full Va" depth NOTE: taper shown is exaggerated No. 38 Shop Notes 29 |