43 - Build Your Own Dovetail Jig, страница 29

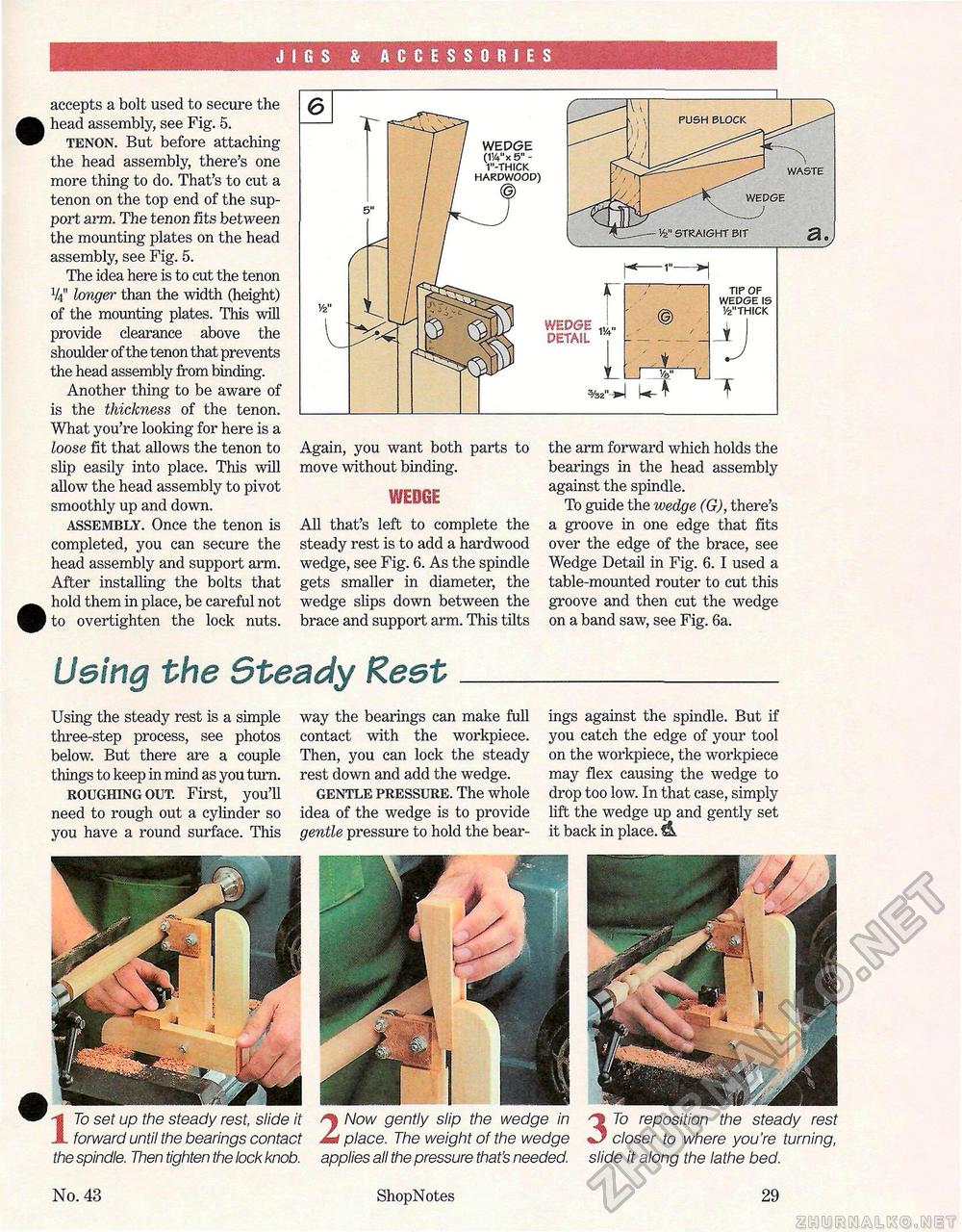

JIGS & ACCESSORIES accepts a bolt used to secure the head assembly, see Fig. 5. TENON. But before attaching the head assembly, there's one more thing to do. That's to cut a tenon on the top end of the support arm. The tenon fits between the mounting plates on the head assembly, see Fig. 5. The idea here is to cut the tenon V4" longer than the width (height) of the mounting plates. This will provide clearance above the shoulder of the tenon that prevents the head assembly from binding. Another thing to be aware of is the thickness of the tenon. What you're looking for here is a loose fit that allows the tenon to slip easily into place. This will allow the head assembly to pivot smoothly up and down. ASSEMBLY. Once the tenon is completed, you can secure the head assembly and support arm. After installing the bolts that hold them in place, be careful not to overtighten the lock nuts. wedge (Wx 5" -1"-THICK HARDWOOD) WASTE WEDGE ■ Vz" STRAIGHT BIT gl • WEDGE DETAIL w 3/32" k-f TIP OF WEDGE IS V211 THICK J 1 Again, you want both parts to move without binding. WEDGE All that's left to complete the steady rest is to add a hardwood wedge, see Fig. 6. As the spindle gets smaller in diameter, the wedge slips down between the brace and support arm. This tilts the arm forward which holds the bearings in the head assembly against the spindle. To guide the wedge (G), there's a groove in one edge that fits over the edge of the brace, see Wedge Detail in Fig. 6. I used a table-mounted router to cut this groove and then cut the wedge on a band saw, see Fig. 6a. Using the Steady RestUsing the steady rest is a simple three-step process, see photos below. But there are a couple things to keep in mind as you turn. ROUGHING OUT. First, you'll need to rough out a cylinder so you have a round surface. This way the bearings can make full contact with the workpiece. Then, you can lock the steady rest down and add the wedge. GENTLE PRESSURE. The whole idea of the wedge is to provide gentle pressure to hold the bear ings against the spindle. But if you catch the edge of your tool on the workpiece, the workpiece may flex causing the wedge to drop too low. In that case, simply lift the wedge up and gently set it back in place. & 2 Now gently slip the wedge in To reposition the steady rest place. The weight of the wedge closer to where you're turning, applies all the pressure that's needed, slide it along the lathe bed. ShopNotes 29 1T0 set up the steady rest, slide it forward until the bearings contact the spindle. Then tighten the lock knob. No. 43 |