44 - Grinding Station, страница 30

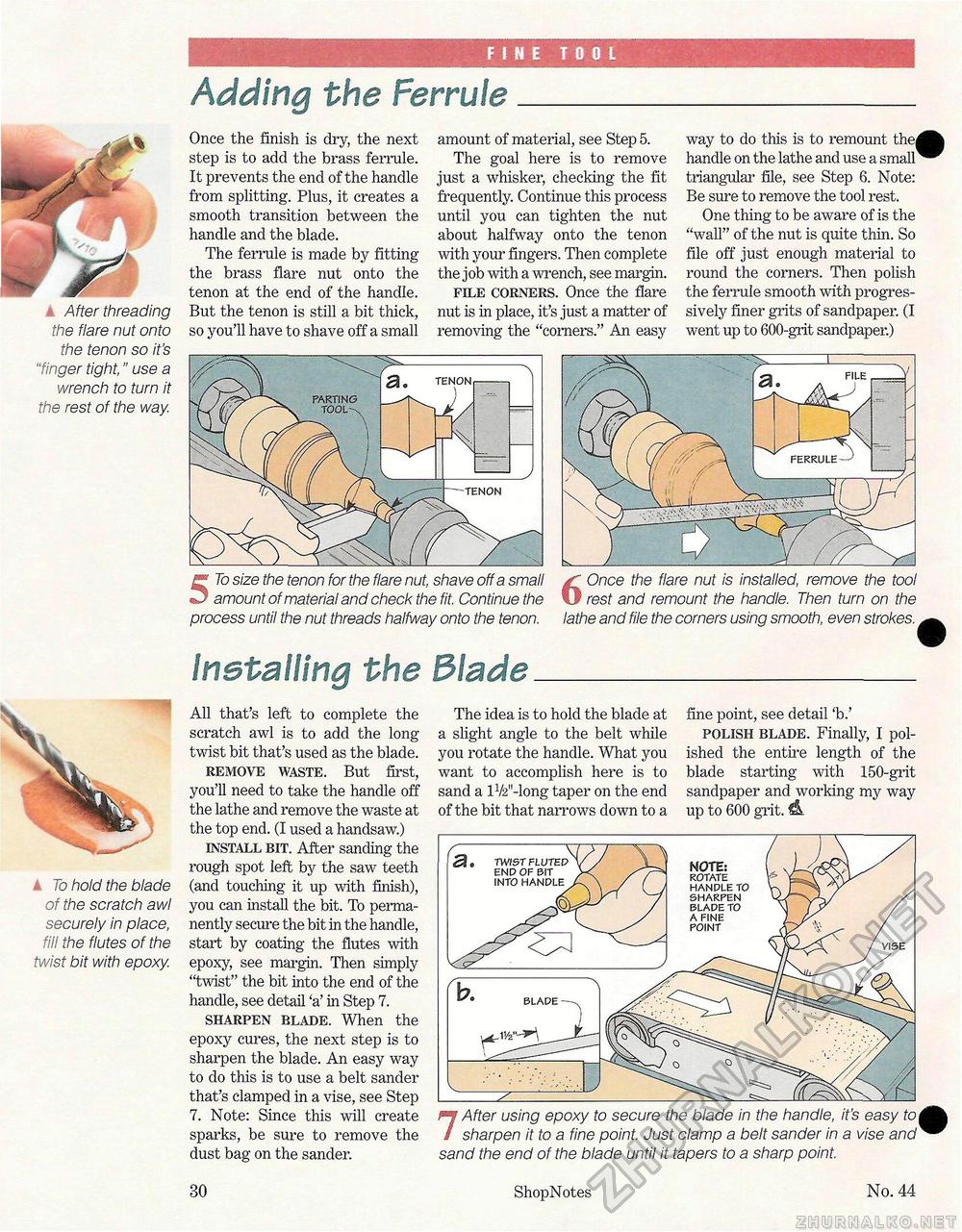

FINE TOOL Adding the Ferrule After threading the flare nut onto the tenon so it's "finger tight," use a wrench to turn it the rest of the way. TENON Once the finish is dry, the next step is to add the brass ferrule. It prevents the end of the handle from splitting. Plus, it creates a smooth transition between the handle and the blade. The ferrule is made by fitting the brass flare nut onto the tenon at the end of the handle. But the tenon is still a bit thick, so you'll have to shave off a small amount of material, see Step 5. The goal here is to remove just a whisker, checking the fit frequently. Continue this process until you can tighten the nut about halfway onto the tenon with your fingers. Then complete the job with a wrench, see margin. file corners. Once the flare nut is in place, it's just a matter of removing the "corners." An easy way to do this is to remount thej handle on the lathe and use a small triangular file, see Step 6. Note: Be sure to remove the tool rest. One thing to be aware of is the "wall" of the nut is quite thin. So file off just enough material to round the corners. Then polish the ferrule smooth with progressively finer grits of sandpaper. (I went up to 600-grit sandpaper.) J To hold the blade of the scratch awl securely in place, fill the flutes of the twist bit with epoxy. 5 To size the tenon for the flare nut, shave off a small amount of material and check the fit. Continue the process until the nut threads halfway onto the tenon. Installing the Blade Once the flare nut is installed, remove the tool rest and remount the handle. Then turn on the lathe and file the corners using smooth, even strokes. All that's left to complete the scratch awl is to add the long twist bit that's used as the blade. remove waste. But first, you'll need to take the handle off the lathe and remove the waste at the top end. (I used a handsaw.) install bit. After sanding the rough spot left by the saw teeth (and touching it up with finish), you can install the bit. To permanently secure the bit in the handle, start by coating the flutes with epoxy, see margin. Then simply "twist" the bit into the end of the handle, see detail 'a' in Step 7. sharpen blade. When the epoxy cures, the next step is to sharpen the blade. An easy way to do this is to use a belt sander that's clamped in a vise, see Step 7. Note: Since this will create sparks, be sure to remove the dust bag on the sander. The idea is to hold the blade at a slight angle to the belt while you rotate the handle. What you want to accomplish here is to sand a iW-long taper on the end of the bit that narrows down to a fine point, see detail 'b.' polish blade. Finally, I polished the entire length of the blade starting with 150-grit sandpaper and working my way up to 600 grit. & 7 After using epoxy to secure the blade in the handle, it's easy to< sharpen it to a fine point. Just clamp a belt sander in a vise and sand the end of the blade until it tapers to a sharp point. BLADE — ^ vise NOTE: ROTATE HANDLE TO SHARPEN BLADE TO A FINE POINT TWIST FLUTEP END OF BIT INTO HANDLE 30 ShopNotes No. 44 |