44 - Grinding Station, страница 28

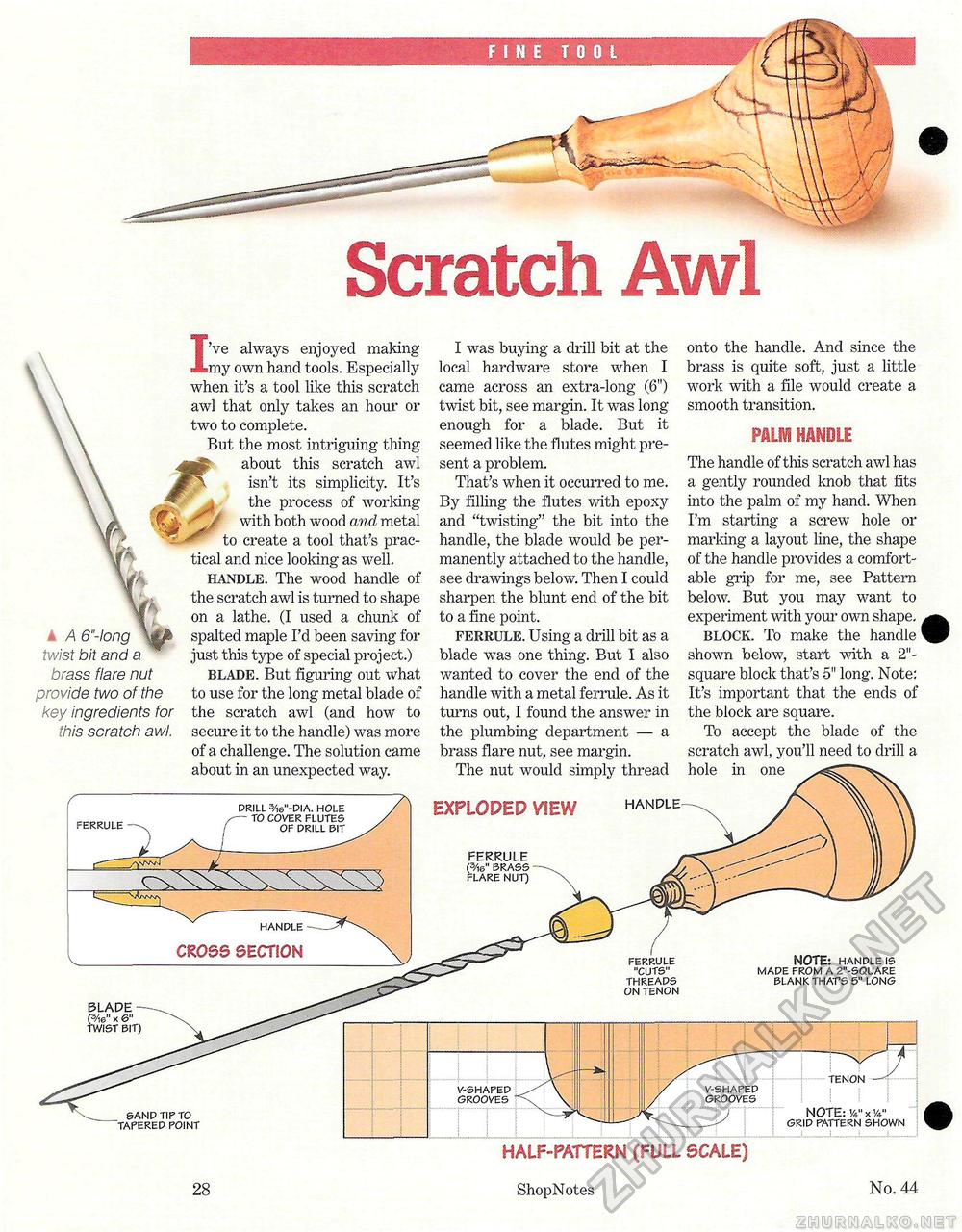

Scratch Awl onto the handle. And since the brass is quite soft, just a little work with a file would create a smooth transition. I was buying a drill bit at the local hardware store when I came across an extra-long (6") twist bit, see margin. It was long enough for a blade. But it seemed like the flutes might present a problem. That's when it occurred to me. By filling the flutes with epoxy and "twisting" the bit into the handle, the blade would be permanently attached to the handle, see drawings below. Then I could sharpen the blunt end of the bit to a fine point. ferrule. Using a drill bit as a blade was one thing. But I also wanted to cover the end of the handle with a metal ferrule. As it turns out, I found the answer in the plumbing department — a brass flare nut, see margin. The nut would simply thread I've always enjoyed making my own hand tools. Especially when it's a tool like this scratch awl that only takes an hour or two to complete. But the most intriguing thing ■C about this scratch awl v isn't its simplicity. It's the process of working ^, / with both wood and metal to create a tool that's practical and nice looking as well. handle. The wood handle of the scratch awl is turned to shape on a lathe. (I used a chunk of spalted maple I'd been saving for just this type of special project.) blade. But figuring out what to use for the long metal blade of the scratch awl (and how to secure it to the handle) was more of a challenge. The solution came about in an unexpected way. The handle of this scratch awl has a gently rounded knob that fits into the palm of my hand. When I'm starting a screw hole or marking a layout line, the shape of the handle provides a comfortable grip for me, see Pattern below. But you may want to experiment with your own shape. block. To make the handle shown below, start with a 2"-square block that's 5" long. Note: It's important that the ends of the block are square. To accept the blade of the scratch awl, you'll need to drill a hole in one /A 6"-long MM twist bit and a brass flare nut provide two of the key ingredients for this scratch awl. HANDLE EXPLODED VIEW drill 3/i6"-dia. hole — to cover flutes of drill bit FERRULE (3/ie" brass flare nut) handle CROSS SECTION NOTE; handle is made from a 2"-square blank thats 5" long ferrule "cuts" threads on tenon BLADE- (3/l6" x 6" twist bit) tenon v-shaped grooves v-shaped grooves NOTE: </4" X y4" grid pattern shown sand tip to "tapered point HALF-PATTERN (FULL SCALE) 28 ShopNotes No. 44 |