44 - Grinding Station, страница 25

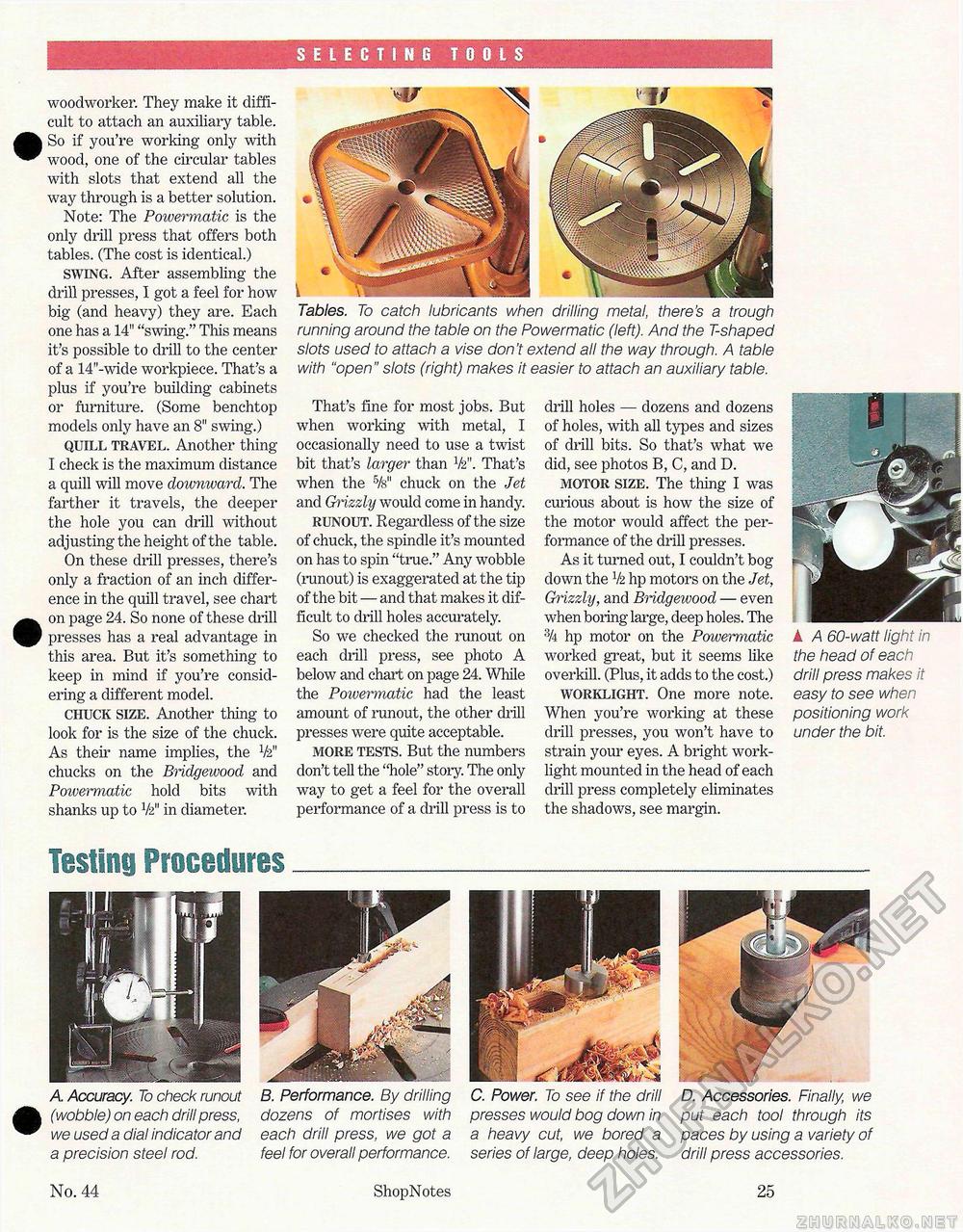

SELECTING TOOLS woodworker. They make it difficult to attach an auxiliary table. So if you're working only with wood, one of the circular tables with slots that extend all the way through is a better solution. Note: The Powermatic is the only drill press that offers both tables. (The cost is identical.) swing. After assembling the drill presses, I got a feel for how big (and heavy) they are. Each one has a 14" "swing." This means it's possible to drill to the center of a 14 "-wide workpiece. That's a plus if you're building cabinets or furniture. (Some benchtop models only have an 8" swing.) quill travel. Another thing I check is the maximum distance a quill will move doivnivard. The farther it travels, the deeper the hole you can drill without adjusting the height of the table. On these drill presses, there's only a fraction of an inch difference in the quill travel, see chart on page 24. So none of these drill presses has a real advantage in this area. But it's something to keep in mind if you're considering a different model. chuck size. Another thing to look for is the size of the chuck. As their name implies, the V211 chucks on the Bndgeivood and Powermatic hold bits with shanks up to V2" in diameter. A A 60-watt light in the head of each drill press makes it easy to see when positioning work under the bit. Tables. To catch lubricants when drilling metal, there's a trough running around the table on the Powermatic (left). And the T-shaped slots used to attach a vise don't extend all the way through. A table with "open" slots (right) makes it easier to attach an auxiliary table. That's tine for most jobs. But when working with metal, I occasionally need to use a twist bit that's larger than V2". That's when the 5/8M chuck on the Jet and Grizzly would come in handy. runout. Regardless of the size of chuck, the spindle it's mounted on has to spin "true." Any wobble (runout) is exaggerated at the tip of the bit — and that makes it difficult to drill holes accurately. So we checked the runout on each drill press, see photo A below and chart on page 24. While the Powermatic had the least amount of runout, the other drill presses were quite acceptable. more tests. But the numbers don't tell the "hole" story. The only way to get a feel for the overall performance of a drill press is to drill holes — dozens and dozens of holes, with all types and sizes of drill bits. So that's what we did, see photos B, C, and D. motor size. The thing I was curious about is how the size of the motor would affect the performance of the drill presses. As it turned out, I couldn't bog down the V2 hp motors on the Jet, Giizzly, and Bridgewood — even when boring large, deep holes. The % hp motor on the Powermatic worked great, but it seems like overkill. (Plus, it adds to the cost.) worklight. One more note. When you're working at these drill presses, you won't have to strain your eyes. A bright work-light mounted in the head of each drill press completely eliminates the shadows, see margin. Testing Procedures A. Accuracy. To check runout (wobble) on each drill press, we used a dial indicator and a precision steel rod. No. 44 B. Performance. By drilling dozens of mortises with each drill press, we got a feel for overall performance. ShopNotes 25 C. Power. To see if the drill presses would bog down in a heavy cut, we bored a series of large, deep holes. D. Accessories. Finally, we put each tool through its paces by using a variety of drill press accessories. |