44 - Grinding Station, страница 26

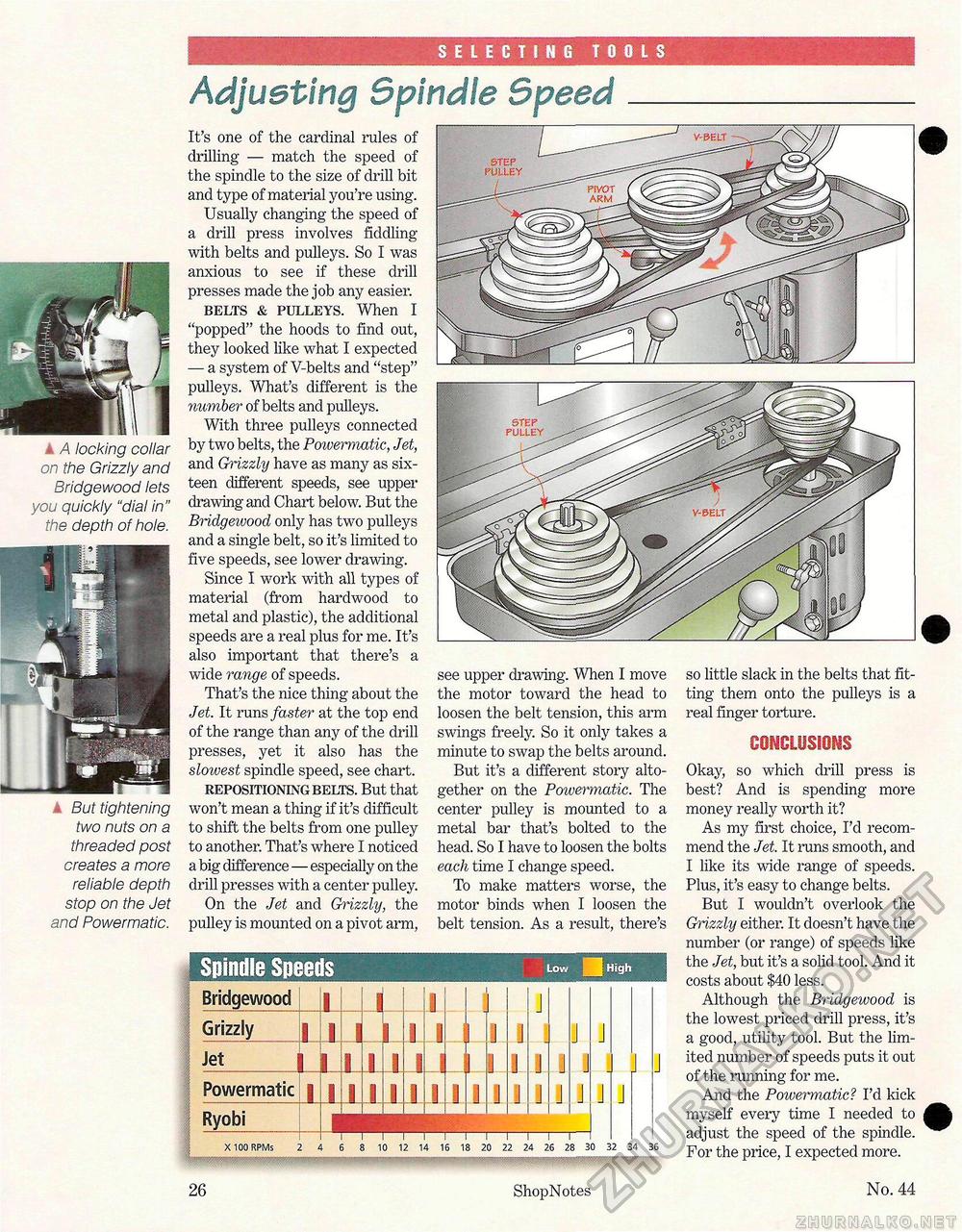

SELECTING TOOLS Adjueting Spindle SpeedA locking collar on the Grizzly and Bridgewood lets you quickly "dial in" the depth of hole. But tightening two nuts on a threaded post creates a more reliable depth stop on the Jet and Powermatic. It's one of the cardinal rules of drilling — match the speed of the spindle to the size of drill bit and type of material you're using. Usually changing the speed of a drill press involves fiddling with belts and pulleys. So I was anxious to see if these drill presses made the job any easier. belts & pulleys. When I "popped" the hoods to find out, they looked like what I expected — a system of V-belts and "step" pulleys. What's different is the number of belts and pulleys. With three pulleys connected by two belts, the Poivermatic, Jet, and Chi.zzly have as many as sixteen different speeds, see upper drawing and Chart below. But the Bridgewood only has two pulleys and a single belt, so it's limited to five speeds, see lower drawing. Since I work with all types of material (from hardwood to metal and plastic), the additional speeds are a real plus for me. It's also important that there's a wide range of speeds. That's the nice thing about the Jet. It runs faster at the top end of the range than any of the drill presses, yet it also has the sloivest spindle speed, see chart. repositioning belts. But that won't mean a thing if it's difficult to shift the belts from one pulley to another. That's where I noticed a big difference — especially on the drill presses with a center pulley. On the Jet and Grizzly, the pulley is mounted on a pivot arm, Spindle Speeds see upper drawing. When I move the motor toward the head to loosen the belt tension, this arm swings freely. So it only takes a minute to swap the belts around. But it's a different story altogether on the Powermatic. The center pulley is mounted to a metal bar that's bolted to the head. So I have to loosen the bolts each time I change speed. To make matters worse, the motor binds when I loosen the belt tension. As a result, there's

10 12 14 16 18 20 22 24 26 28 30 32 34 36 10 12 14 16 18 20 22 24 26 28 30 32 34 36 so little slack in the belts that fitting them onto the pulleys is a real finger torture. CONCLUSIONS Okay, so which drill press is best? And is spending more money really worth it? As my first choice, I'd recommend the Jet. It runs smooth, and I like its wide range of speeds. Plus, it's easy to change belts. But I wouldn't overlook the Grizzly either. It doesn't have the number (or range) of speeds like the Jet, but it's a solid tool. And it costs about $40 less. Although the Bridgewood is the lowest priced drill press, it's a good, utility tool. But the limited number of speeds puts it out of the running for me. And the Poivermatic? I'd kick myself every time I needed to adjust the speed of the spindle. For the price, I expected more. STEP PULLEY PIVOT ARM STEP PULLEY 26 ShopNotes No. 44 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||