51 - Band Saw Upgrade, страница 32

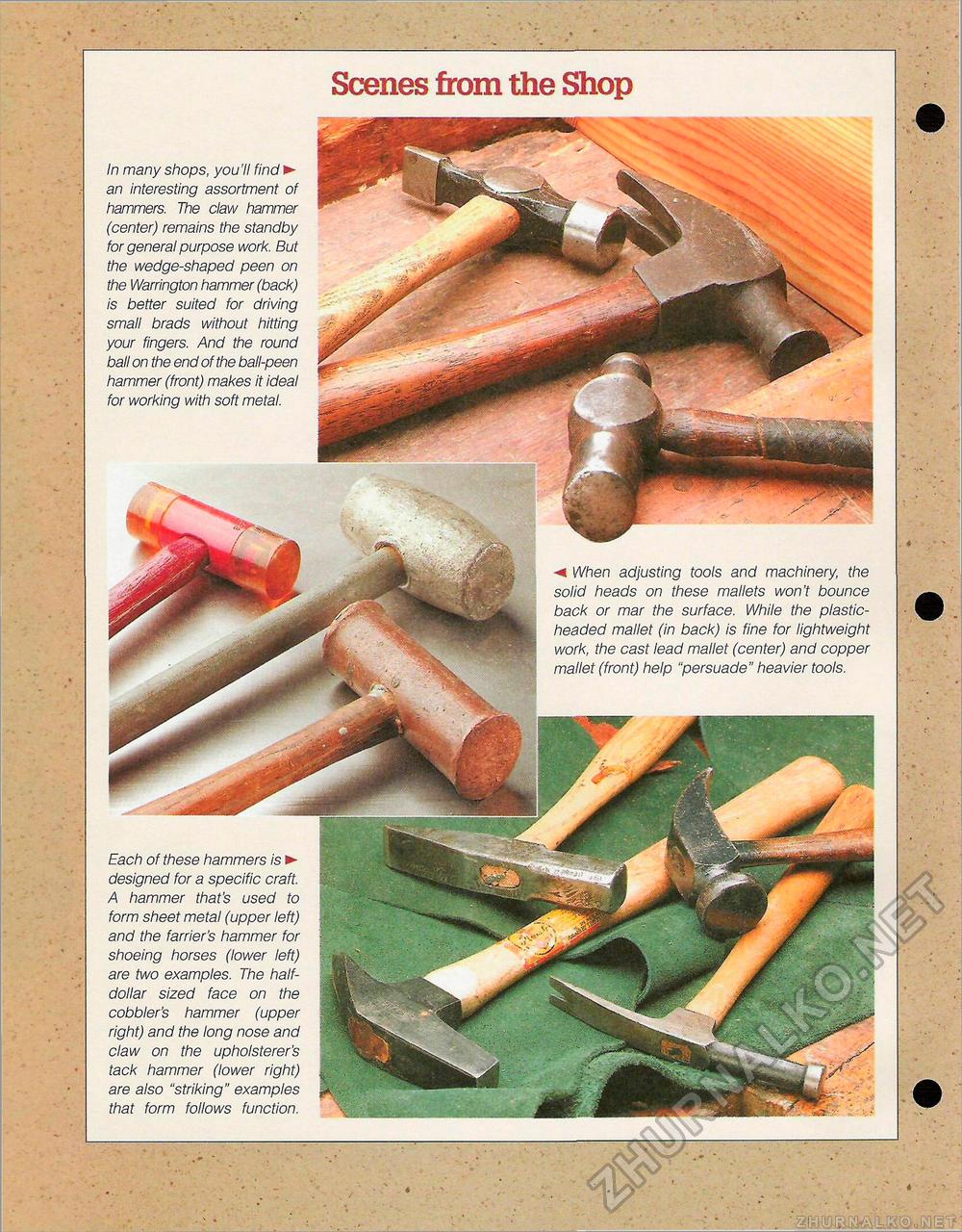

Scenes from the Shop M When adjusting tools and machinery, the solid heads on these mallets won't bounce back or mar the surface. While the plastic-headed mallet (in back) is fine for lightweight work, the cast lead mallet (center) and copper mallet (front) help "persuade" heavier tools. In many shops, you'll find ► an interesting assortment of hammers. The claw hammer (center) remains the standby for general purpose work. But the wedge-shaped peen on the Warrington hammer (back) is better suited for driving small brads without hitting your fingers. And the round ball on the end of the ball-peen hammer (front) makes it ideal for working with soft metal. Each of these hammers is ► designed for a specific craft. A hammer that's used to form sheet metal (upper left) and the farrier's hammer for shoeing horses (lower left) are two examples. The half-dollar sized face on the cobbler's hammer (upper right) and the long nose and claw on the upholsterer's tack hammer (lower right) are also "striking" examples that form follows function. |