58 - Miter Saw Station, страница 5

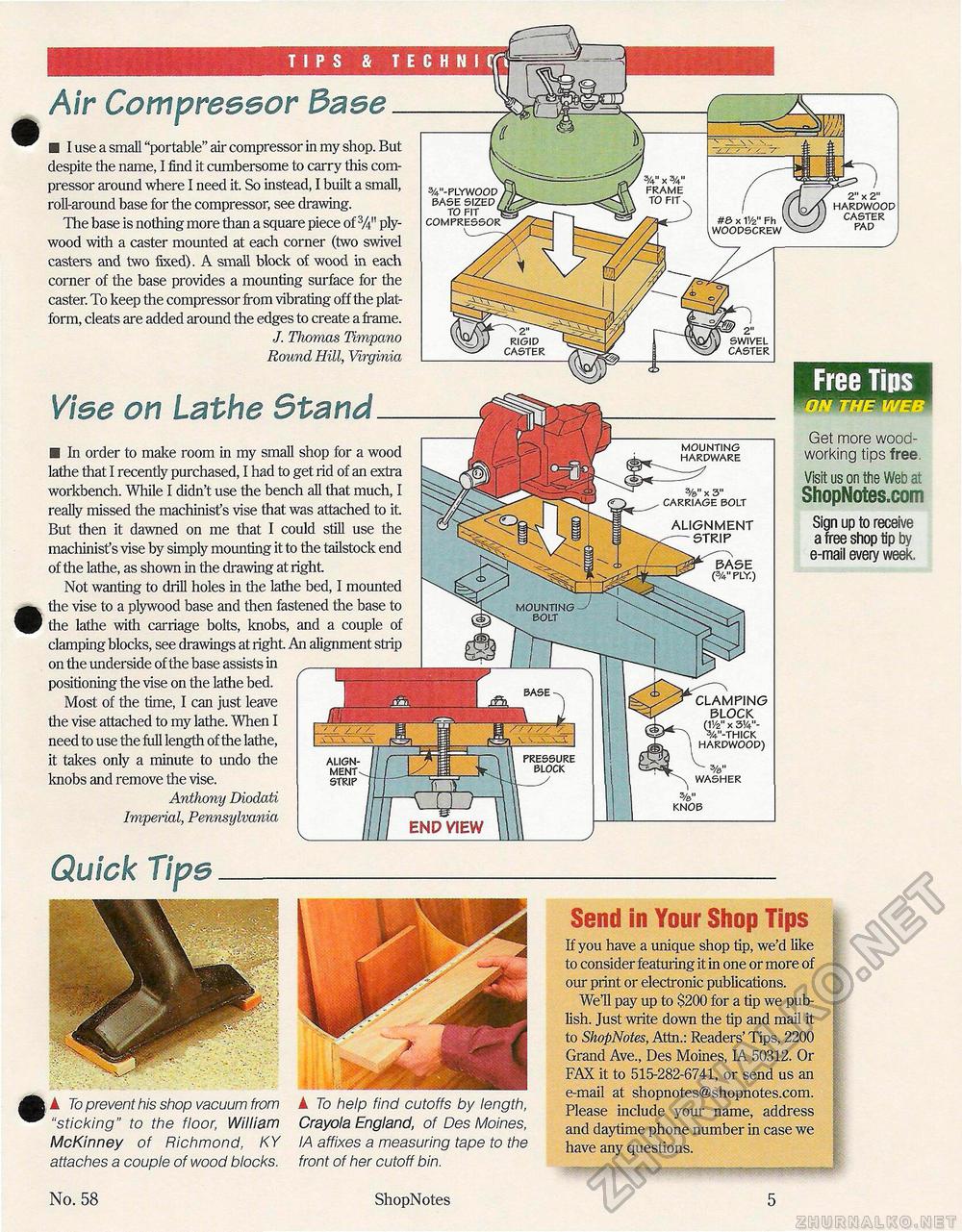

Quick Tips^fc A To prevent his shop vacuum from ^^ "sticking" to the floor, William McKinney of Richmond, KY attaches a couple of wood blocks. A To help find cutoffs by length, Crayola England, of Des Moines, I A affixes a measuring tape to the front of her cutoff bin. Send in Your Shop Tips If you have a unique shop tip, we'd like to consider featuring it in one or more of our print or electronic publications. Well pay up to $200 for a tip we publish. Just write down the tip and mail it to ShopNotes, Attn.: Readers' Tips, 2200 Grand Ave., Des Moines, IA 50312. Or FAX it to 515-282-6741, or send us an e-mail at shopnotes@shopnotes.com. Please include your name, address and daytime phone number in case we have any questions. %" X 3/4" FRAME TO FIT- #8> x V/z" Fh * WOODSCREW SWIVEL CASTER RIGID CASTER TIPS & TECHNIC! Get more woodworking tips free. Visit us on the Web at ShopNotes.com Sign up to receive a free shop tip by e-mail every week. Air Compressor Base■ I use a small "portable" air compressor in my shop. But despite the name, I find it cumbersome to carry this compressor around where I need it. So instead, I built a small, roll-around base for the compressor, see drawing. The base is nothing more than a square piece of:plywood with a caster mounted at each corner (two swivel casters and two fixed). A small block of wood in each corner of the base provides a mounting surface for the caster. To keep the compressor from vibrating off the platform, cleats are added around the edges to create a frame. J. Thomas Timpano Round Hill, Virginia Vise on lathe Stand■ In order to make room in my small shop for a wood lathe that I recently purchased, I had to get rid of an extra workbench. While I didn't use the bench all that much, I really missed the machinist's vise that was attached to it But then it dawned on me that I could still use the machinist's vise by simply mounting it to the tailstock end of the lathe, as shown in the drawing at right Not wanting to drill holes in the lathe bed, I mounted the vise to a plywood base and then fastened the base to the lathe with carriage bolts, knobs, and a couple of clamping blocks, see drawings at right. An alignment strip on the underside of the base assists in positioning the vise on the lathe bed. Most of the time, I can just leave the vise attached to my lathe. When I need to use the fall length of the lathe, it takes only a minute to undo the knobs and remove the vise. Anthony Diodati Imperial, Pennsylvania MOUNTING HARDWARE 3/g" x 3" CARRIAGE BOLT ALIGNMENT STRIP ) CLAMPING BLOCK y/2" x 3>/4"-V-THICK IARDWOOD) WASHER KNOB No. 58 ShopNotes 5 |