79 - Slant Front Tool Cart, страница 42

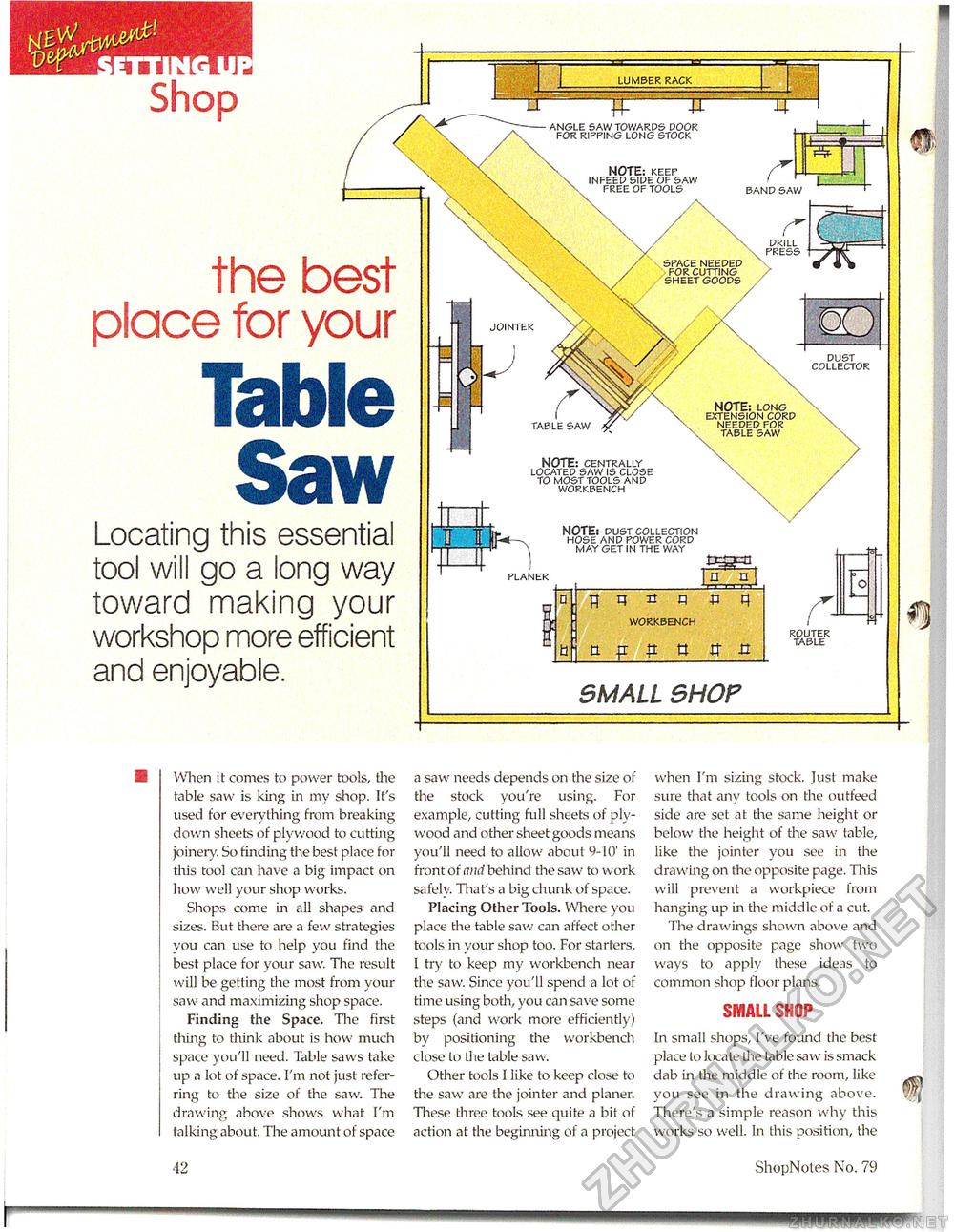

LUMBER RACK ANGLE SAW TOWARDS DOOR FOR RIPPING LONG STOCK NOTE: KEEP INFEEP SIDE OF SAW FREE OF TOOLS BAND SAW drill press the best place for your SPACE NEEDED FOR CUTTING SHEET GOODS JOINTER DUST COLLECTOR NOTE: LONG EXTENSION CORD NEEDED FOR TABLE SAW TABLE SAW NOTE: CENTRALLY LOCATED SAW IS CLOSE TO MOSTTOOLS AND WORKBENCH Locating this essential tool will go a long way toward making your workshop more efficient and enjoyable. NOTE: DUST COLLECTION HOSE AND POWER CORD MAY GET IN THE WAY PLANER WORKBENCH router table Hf| P. f ft tt XT a SMALL 3H0P YVhen it comes to power tools, the table saw is king in my shop. It's used for everything from breaking down sheets of plywood to cutting joinery. So finding the best place for this tool can have a big impact on how well your shop works. Shops come in all shapes and sizes. But there are a few strategies you can use to help you find the best place for your saw. The result will be getting the most from your saw and maximizing shop space. Finding the Space. The first thing to think about is how much space you'll need. Table saws take up a lot of space. I'm not just referring to the size of the saw. The drawing above shows what I'm talking about. The amount of space a saw needs depends on the size of the stock you're using. For example, cutting full sheets of plywood and other sheet goods means you'll need to allow about 9-10' in front of and behind the saw to work safely. That's a big chunk of space. Placing Other Tools. Where you place the table saw can affect other tools in your shop too. For starters, I try to keep my workbench near the saw. Since you'll spend a lot of time using both, you can save some steps (and work more efficiently) by positioning the workbench close to the table saw. Other tools I like to keep close to the saw are the jointer and planer. These three tools see quite a bit of action at the beginning of a project when I'm sizing stock. Just make sure that any tools on the outfeed side are set at the same height or below the height of the saw table, like the jointer you see in the drawing on the opposite page. This will prevent a workpiece from hanging up in the middle of a cut. The drawings shown above and on the opposite page show two ways to apply these ideas to common shop floor plans. SMALL SHOP In small shops, I've found the best place to locate the table saw is smack dab in the middle of the room, like you see in the drawing above. Wf There's a simple reason why this works so well. In this position, the 42 ShopNotes No. 79 I |