79 - Slant Front Tool Cart, страница 39

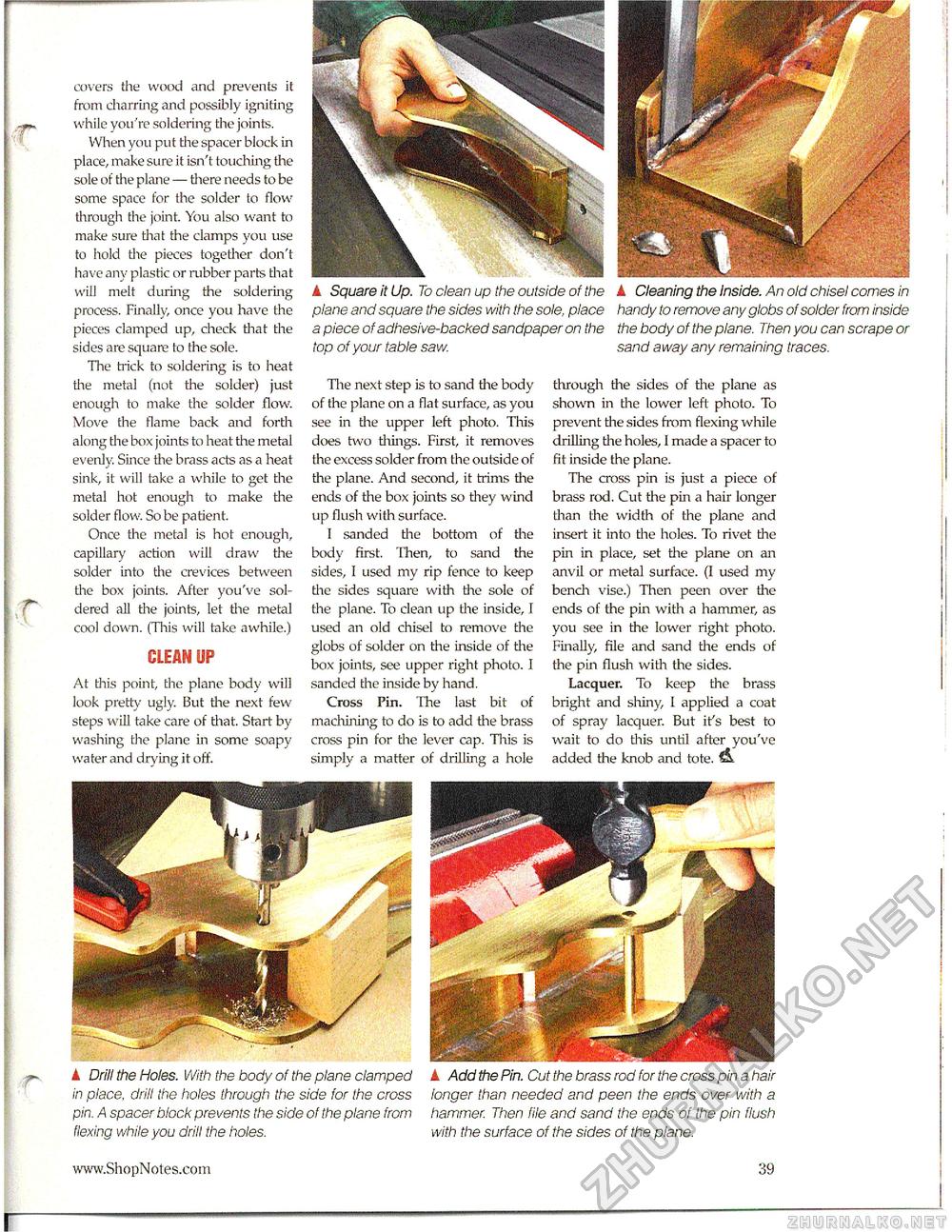

■f r re covers the wood and prevents it from charring and possibly igniting while you're soldering the joints. When you put the spacer block in place, make sure it isn't touching the sole of the plane — there needs to be some space for the solder to flow through the joint. You also want to make sure that the clamps you use to hold the pieces together don't have any plastic or rubber parts that will melt during the soldering process. Finally, once you have the pieces clamped up, check that the sides are square to the sole. The trick to soldering is to heat the metal (not the solder} just enough to make the solder flow. Move the flame back and forth along the box joints to heat the metal evenly. Since the brass acts as a heat sink, it will take a while to get the metal hot enough to make the solder flow. So be patient. Once the metal is hot enough, capillary action will draw the solder into the crevices between the box joints. After you've soldered all tlie joints, let the metal cool down. (Tliis will take awhile.) CLEAN UP At tliis point, the plane body will look pretty ugly. But the next few-steps will take care of that. Start by washing the plane in some soapy water and drying it off. 1 Square it Up. To clean up the outside of the plane and square the sides with the sole, place a piece of adhesive-backed sandpaper on the top of your table saw. A Cleaning the Inside. An old chisel comes in handy to remove any globs of solder from inside the body of the plane. Then you can scrape or sand away any remaining traces. The next step is to sand the body of the plane on a flat surface, as you see in the upper left photo. Tliis does two things. First, it removes the excess solder from the outside of the plane. And second, it trims the ends of the box joints so they wind up flush with surface. 1 sanded the bottom of the bodv first. Then, to sand the ^ * sides, I used my rip fence to keep the sides square with the sole of the plane. To clean up the inside, I used an old chisel to remove the globs of solder on the inside of the box joints, see upper right photo. I sanded the inside by hand. Cross Fin. The last bit of machining to do is to add the brass cross pin for the lever cap. Tliis is simply a matter of drilling a hole through the sides of the plane as shown in the lower left photo. To prevent the sides from flexing while drilling the holes, I made a spacer to fit inside the plane. The cross pin is just a piece of brass rod. Cut the pin a hair longer than the width of the plane and insert it into die holes. To rivet the pin in place, set the plane on an anvil or metal surface. (1 used my bench vise.) Then peen over the ends of the pin with a hammer, as you see in the lower right photo. Finally, file and sand the ends of the pin flush with the sides. Lacquer. To keep the brass bright and shiny, I applied a coat of spray lacquer. But it's best to wait to do tliis until after you've added the knob and tote. <1 A Drill the Holes. With the body of the plane clamped in place, drill the holes through the side for the cross pin. A spacer block prevents the side of the plane from flexing while you drill the holes. A Add tie Pin. Cut the brass rod for the cross pin a hair longer than needed and peen the ends over with a hammer. Then file and sand the ends of the pin flush with the surface of the sides of the plane. www.Shop N ol es.com 39 r |