79 - Slant Front Tool Cart, страница 38

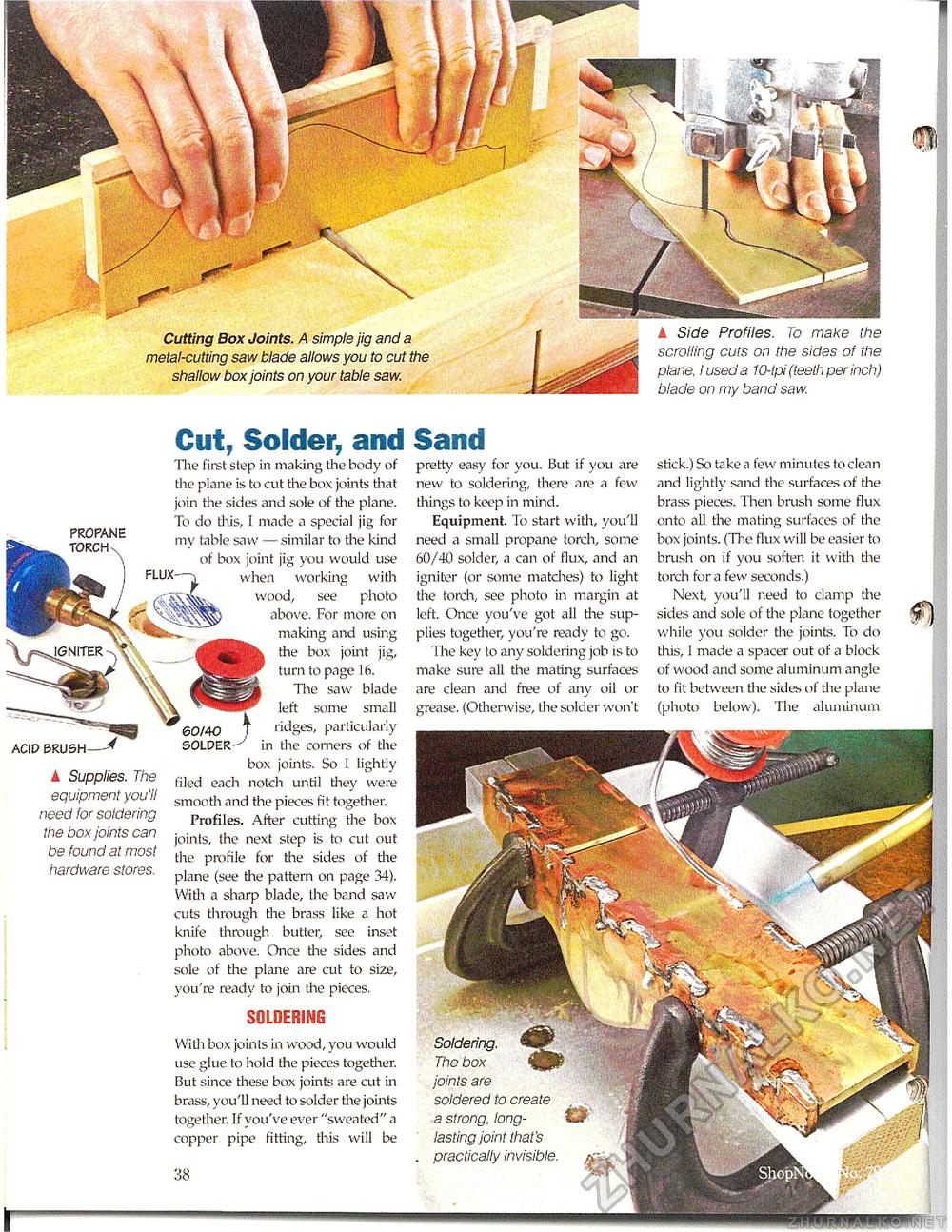

A Side Profiles. To make the scrolling cuts on the sides of the plane, I used a 10-tpi (teeth per inch) blade on my band saw. SOLDERING Cut, Solder, anil Sand PROFANE ACID BRUSH 4 Supplies. The equipment you'll need for soldering the box joints can be found at most hardware stores. The first step in making the body of the plane is to cut the box joints that join the sides and sole of the plane-To do this, I made a special jig for my table saw — similar to the kind of box joint jig you would use when working with wood, see photo above. For more on making and using the box joint jig, turn to page lfi. The saw blade left some small • ridges, particularly in the comers of the box joints. So 1 lightly filed each notch mitil they were smooth and the pieces fit together. Profiles. After cutting the box joints, the next step is to cut out the profile for the sides of the plane (see the pattern on page 34). With a sharp blade, the band saw cuts through the brass like a hot knife through butter, see inset photo above. Once the sides and sole of the plane are cut to size, you're ready to join the pieces. bu/w SOLDER pretty easy for you. But if you are new to soldering, there are a few things to keep in mind. Equipment. To start with, you'll need a small propane torch, some 60/40 solder, a can of flux, and an igniter (or some matches) to light the torch, see photo in margin at left. Once you've got all the supplies together, you're ready to go. The key to any soldering job is to make sure all the mating surfaces are clean and free of any oil or grease. (Otherwise, the solder won't stick.) So take a few minutes to clean and lightly sand the surfaces of the brass pieces. Then brush some flux onto all the mating surfaces of the box joints. (The flux will be easier to brush on if you soften it with the torch for a few seconds.) Next, you'll need to clamp the sides and sole of the plane together while you solder the joints. To do this, I made a spacer out of a block of wood and some aluminum angle to fit between the sides of the plane (photo below). The aluminum With box joints in wood, you would use glue to hold the pieces together. But since these box joints are cut in brass, you'll need to solder the joints together. If you've ever "sweated" a copper pipe fitting, this will be 38 metal-cutting saw blade allows you to cut the shallow box joints on your table saw. joints are soldered to create a strong, long-lasting joint that's practically invisible. |