79 - Slant Front Tool Cart, страница 37

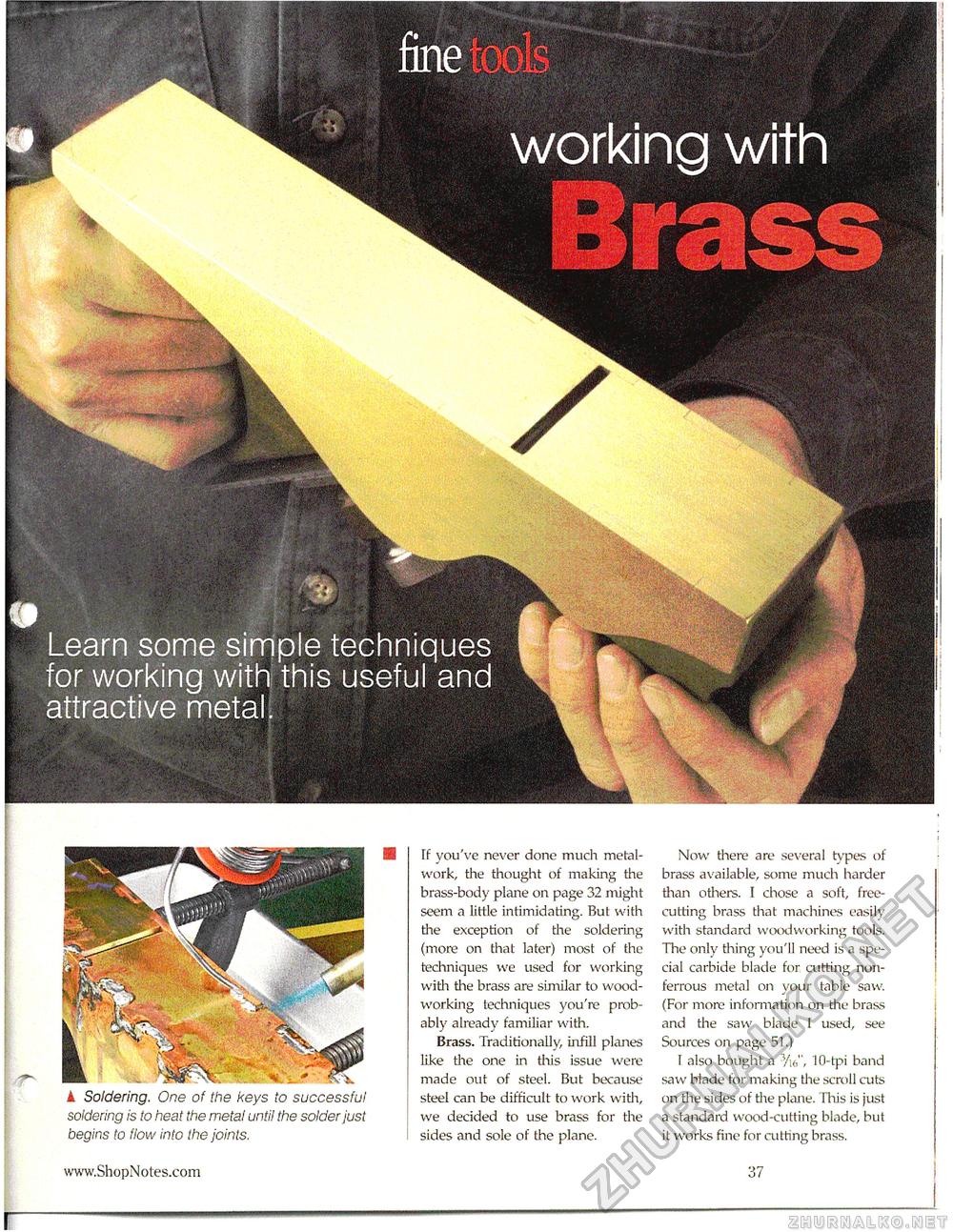

' • : . V;:? mm**? k " Learn some simple techniques for working with this useful and attractive metal. Now there are several types of brass available, some much harder than others. I chose a soft, free-cutting brass that machines easily with standard woodworking tools. The only thing you'll need is a special carbide blade for cutting non-ferrous metal on your table saw. (For more information on the brass and the saw blade 1 used, see Sources on page 51.) I also bought a 3/i<,", 10-tpi band saw blade for making tine scroll cuts on the sides of the plane. This is just a standard wood-cutting blade, but it works fine for cutting brass. 37 If you've never done much metal-work, the thought of making the brass-body plane on page 32 might seem a little intimidating. But with die exception of die soldering (more on that later) most of the techniques we used for working widi the brass are similar to woodworking techniques you're probably already familiar with. Brass. Traditionally, infill planes like die one in this issue were made out of steel. But because steel can be difficult to work with, we decided to use brass for the sides and sole of the plane. A Soldering. One of the keys to successful soldering is to heat the metal until the solder just begins to flow into the joints. |