80 - Heirloom Tool Cabinet, страница 15

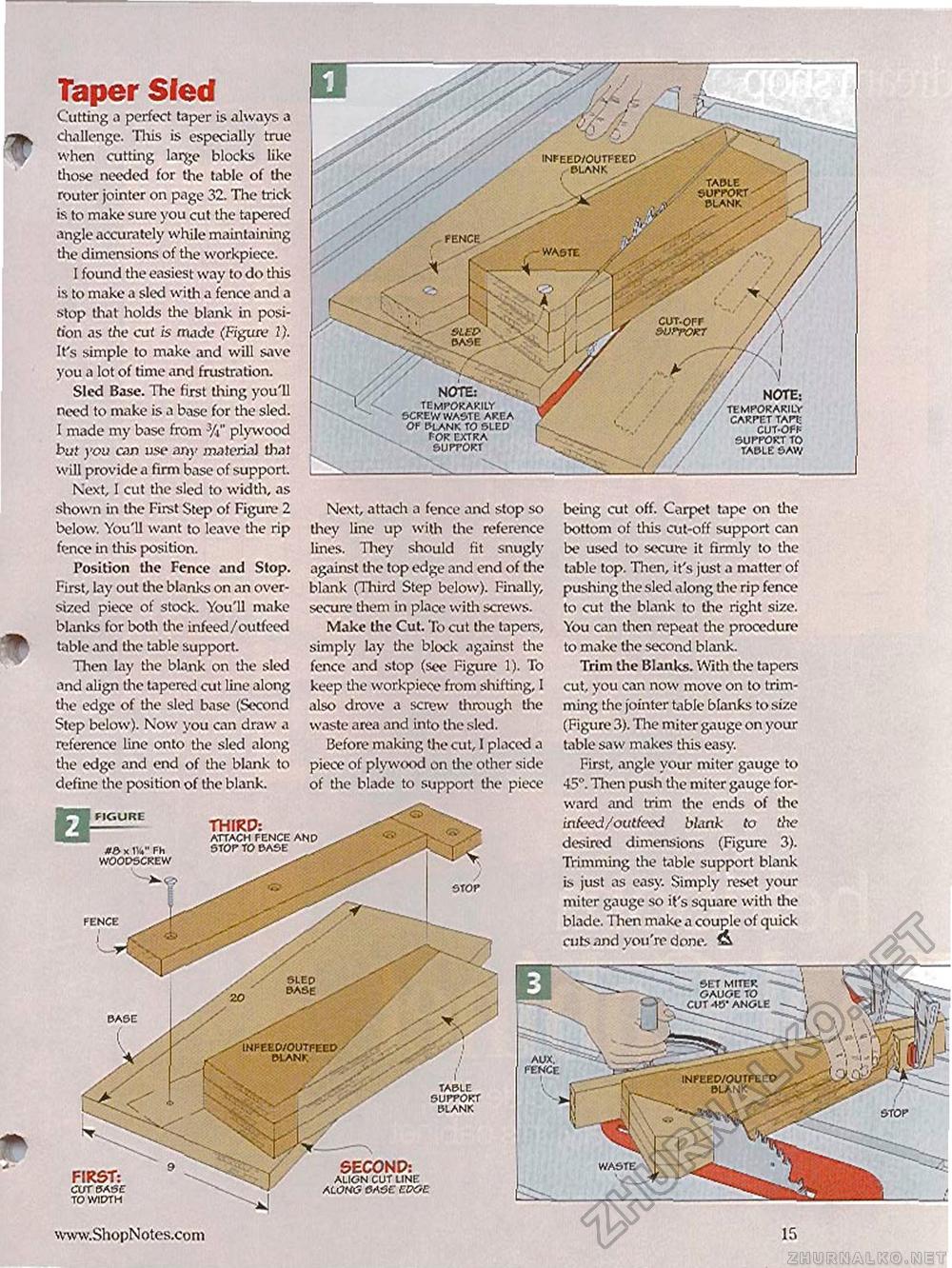

infeed/outfeep . CLANK TABLE SUPPORT BLANK FENCE WASTE CUT-OFF s>urrOK7 NOTE: TEMPORARILY SCREW WASTE AREA OF PLANK TO SLED TOR EXTRA SUPPORT NOTE: TEMPORARILY CARPET TAPS CUT-OFf= SUPPORT TO TABLE SAW SET MITER GAUGE TO CUT-WANGLE INPEED/OUTFEED BLANK - STOP WASTE *Sx1V Fh WOODSCREW STOP FENCE sled base INFEED/OUTFEED ' BLANK / TABLE SUPPORT PLANK Taper Sled Cutting a perfect taper is always a challenge. This is especially true when cutting large blocks like those needed for the table of the router jointer on page 32. The trick is to make sure you cut the tapered angle accurately while maintaining the dimensions of the workpiece. I found the easiest way to do this is to make a sled with a fence and a stop that holds the blank in position as the cut is made (Figure 1). It's simple to make and will save you a lot of time and frustration. Sled Base. The first thing you'll need to make is a base for the sled. I made my base from 3/i" plywood buf you can use any material that will provide a firm base of support. Next, I cut the sled to width, as shown in the First Step of Figure 2 below. You'll want to leave tine rip fence in this position. Position the Fence and Stop. First, lay out the blanks on an oversized piece of stock. You'll make blanks for both tine infeed/outfeed table and the table support. Then lay the blank on the sled and align tine tapered cut line along the edge of the sled base (Second Step below). Now you can draw a reference line onto tine sled along the edge and end of the blank to define the position of the blank. Next, attach a fence and stop so they line up with the reference lines. They should fit snugly against the top edge and end of the blank (Third Step below). Finally, secure them in place with screws. Make the Cut. To cut the tapers, simply lay the block against the fence and stop (see Figure 1). To keep tine workpiece from shifting, I also drove a screw through the waste area and into the sled. Before making the cut, I placed a piece of plywood on tine other side of the blade to support tine piece THIRP: ATTACH FENCE STOP TO BASE FIGURE AND base being cut off. Carpet tape on tine bottom of this cut-off support can be used to secure it firmly to the table top. Then, it's just a matter of pushing tine sled along the rip fence to ait the blank to the right size. You can then repeat tine procedure to make the second blank. Trim the Blanks. With the tapers cut, you can now move on to trimming the jointer table blanks to size (Figure 3). Tine miter gauge on your table saw makes this easy. First, angle your miter gauge to 45°. Then push tine miter gauge forward and trim the ends of tine infeed/out feed Wank to tite desired dimensions (Figure 3). Trimming the table support blank is just as easy. Simply reset your miter gauge so it's square with the blade. Then make a couple of quick cuts and vou'redone. & FIRST: Cl/rSA5C TO WIDTH SECOND: ALIGN CUT LINE ALONG 0AC€ EPOZ AUX. FENCE 15 |