81 - Ultimate Sharpening Station, страница 40

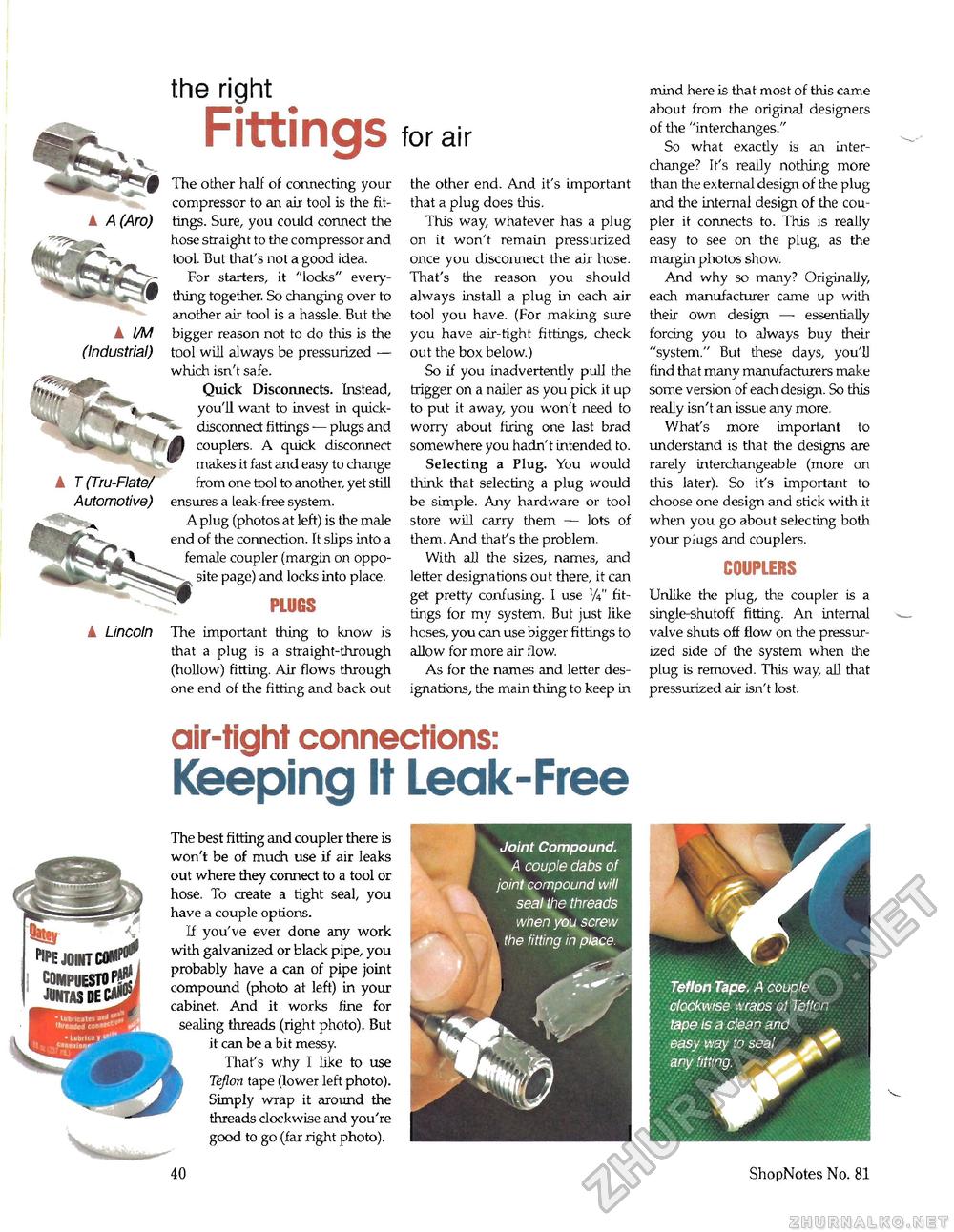

▲ l/M (Industrial) the right FittingsThe other half of connecting your compressor to an air tool is the fittings. Sure, you could connect the hose straight to the compressor and tool. But that's not a good idea. For starters, it "locks" everything together. So changing over to another air tool is a hassle. But the bigger reason not to do this is the tool will always be pressurized — which isn't safe. Quick Disconnects. Instead, you'll want to invest in quick-disconnect fittings — plugs and £ couplers. A quick disconnect makes it fast and easy to change from one tool to another, yet still ensures a leak-free system. A plug (photos at left) is the male end of the connection. It slips into a female coupler (margin on opposite page) and locks into place. PLUGS A Lincoln The important thing to know is that a plug is a straight-through (hollow) fitting. Air flows through one end of the fitting and back out A T(Tru-Flate/ Automotive) for air the other end. And it's important that a plug does this. This way, whatever has a plug on it won't remain pressurized once you disconnect the air hose. That's the reason you should always install a plug in each air tool you have. (For making sure you have air-tight fittings, check out the box below.) So if you inadvertently pull the trigger on a nailer as you pick it up to put it away, you won't need to worry about firing one last brad somewhere you hadn't intended to. Selecting a Plug. You would think that selecting a plug would be simple. Any hardware or tool store will carry them — lots of them. And that7s the problem. With all the sizes, names, and letter designations out there, it can get pretty confusing. I use lA" fittings for my system. But just like hoses, you can use bigger fittings to allow for more air flow. As for the names and letter designations, the main thing to keep in air-tight connections: Keeping It Leak-Freemind here is that most of this came about from the original designers of the "interchanges." So what exactly is an interchange? It's really nothing more than the external design of the plug and the internal design of the coupler it connects to. This is really easy to see on the plug, as the margin photos show. And why so many? Originally, each manufacturer came up with their own design — essentially forcing you to always buy their "system." But these days, you'll find that many manufacturers make some version of each design. So this really isn't an issue any more. What's more important to understand is that the designs are rarely interchangeable (more on this later). So ifs important to choose one design and stick with it when you go about selecting both your piugs and couplers. COUPLERS Unlike the plug, the coupler is a single-shutoff fitting. An internal valve shuts off flow on the pressurized side of the system when the plug is removed. This way, all that pressurized air isn't lost. Joint Compound. A couple dabs of joint compound will seal the threads when you screw the fitting in place. rS<ii ftPEJOWTCOW^ COMPUESTOP^ JUNTAS DE The best fitting and coupler there is won't be of much use if air leaks out where they connect to a tool or hose. To create a tight seal, you have a couple options. If you've ever done any work with galvanized or black pipe, you probably have a can of pipe joint compound (photo at left) in your cabinet. And it works fine for sealing threads (right photo). But it can be a bit messy. That's why I like to use Teflon tape (lower left photo). Simply wrap it around the threads clockwise and you're good to go (far right photo). 40 ShopNotes No. 81 Teflon Tape. A couple clockwise wraps ol Teflon tape is a dean and easy way to seal any fitting. |