81 - Ultimate Sharpening Station, страница 39

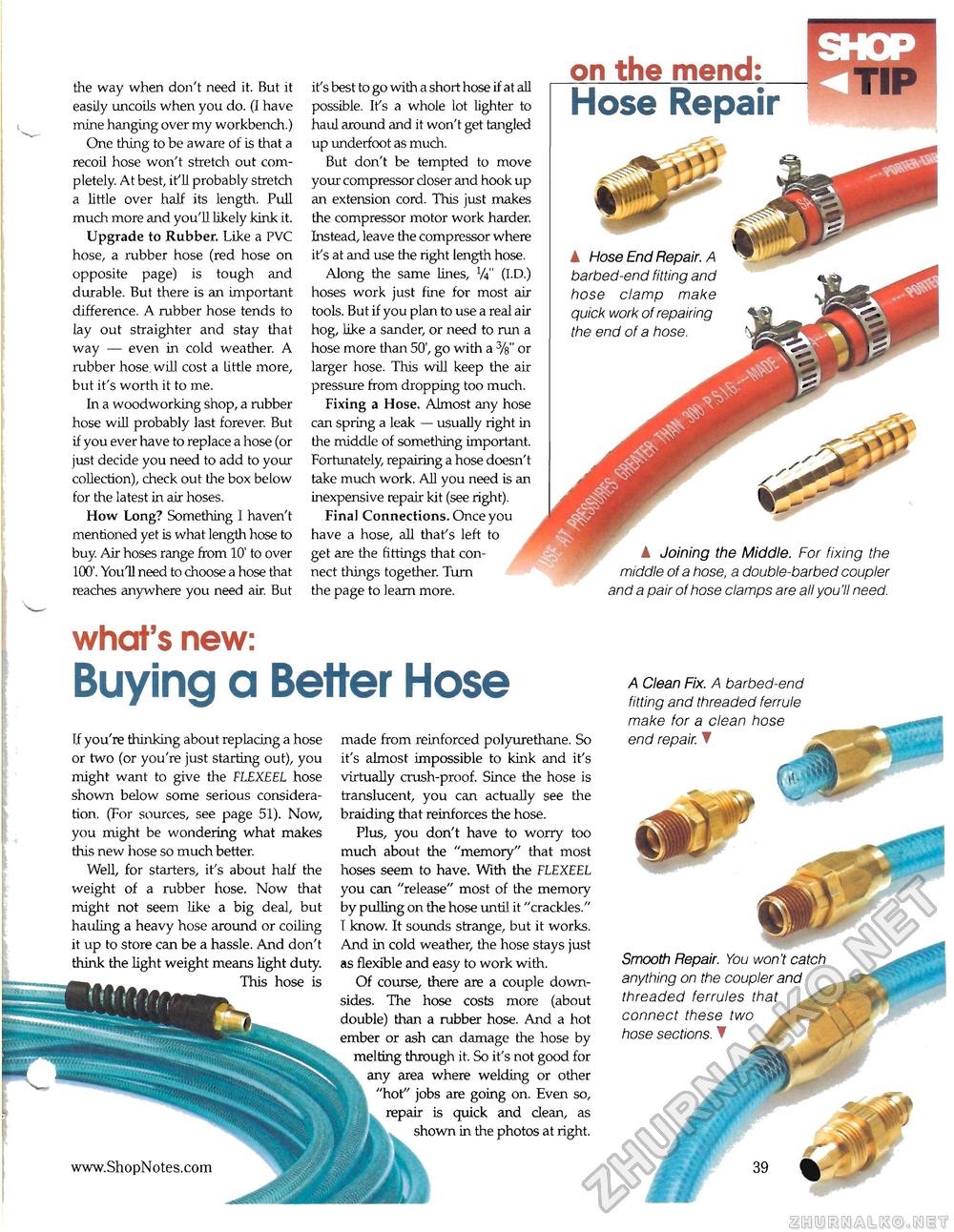

the way when don't need it. But it easily uncoils when you do. (I have mine hanging over my workbench.) One thing to be aware of is that a recoil hose won't stretch out completely. At best, if 11 probably stretch a little over half its length. Pull much more and you'll likely kink it. Upgrade to Rubber. Like a PVC hose, a rubber hose (red hose on opposite page) is tough and durable. But there is an important difference. A rubber hose tends to lay out straighter and stay that way — even in cold weather. A rubber hose will cost a little more, but it's worth it to me. In a woodworking shop, a rubber hose will probably last forever. But if you ever have to replace a hose (or just decide you need to add to your collection), check out the box below for the latest in air hoses. How Long? Something I haven't mentioned yet is what length hose to buy. Air hoses range from 10' to over 100'. YouH need to choose a hose that reaches anywhere you need air. But what's new: Buying a Better Hose it's best to go with a short hose if at all possible. Ifs a whole lot lighter to haul around and it won't get tangled up underfoot as much. But don't be tempted to move your compressor closer and hook up an extension cord. This just makes the compressor motor work harder. Instead, leave the compressor where ifs at and use the right length hose. Along the same lines, W (I.D.) hoses work just fine for most air tools. But if you plan to use a real air hog, like a sander, or need to run a hose more than 50', go with a %" or larger hose. This will keep the air pressure from dropping too much. Fixing a Hose. Almost any hose can spring a leak — usually right in the middle of something important. Fortunately, repairing a hose doesn't take much work. All you need is an inexpensive repair kit (see right). Final Connections. Once you have a hose, all thafs left to get are the fittings that connect things together. Turn the page to learn more. on the mend: Hose Repair ▲ Joining the Middle. For fixing the middle of a hose, a double-barbed coupler and a pair of hose clamps are all you'll need. k Hose End Repair. A barbed-end fitting and hose clamp make quick work of repairing the end of a hose. made from reinforced polyurethane. So it's almost impossible to kink and ifs virtually crush-proof. Since the hose is translucent, you can actually see the braiding that reinforces the hose. Plus, you don't have to worry too much about the "memory" that most hoses seem to have. With the FLEXEEL you can "release" most of the memory by pulling on the hose until it "crackles." I know. It sounds strange, but it works. And in cold weather, the hose stays just as flexible and easy to work with. Of course, there are a couple downsides. The hose costs more (about double) than a rubber hose. And a hot ember or ash can damage the hose by melting through it. So it's not good for any area where welding or other "hof jobs are going on. Even so, repair is quick and clean, as shown in the photos at right. If you're thinking about replacing a hose or two (or you're just starting out), you might want to give the FLEXEEL hose shown below some serious consideration. (For sources, see page 51). Now, you might be wondering what makes this new hose so much better. Well, for starters, ifs about half the weight of a rubber hose. Now that might not seem like a big deal, but hauling a heavy hose around or coiling it up to store can be a hassle. And don't think the light weight means light duty. This hose is Smooth Repair. You won't catch anything on the coupler and threaded ferrules that connect these two hose sections. ▼ A Clean Fix. A barbed-end fitting and threaded ferrule make for a clean hose end repair. ▼ |