81 - Ultimate Sharpening Station, страница 36

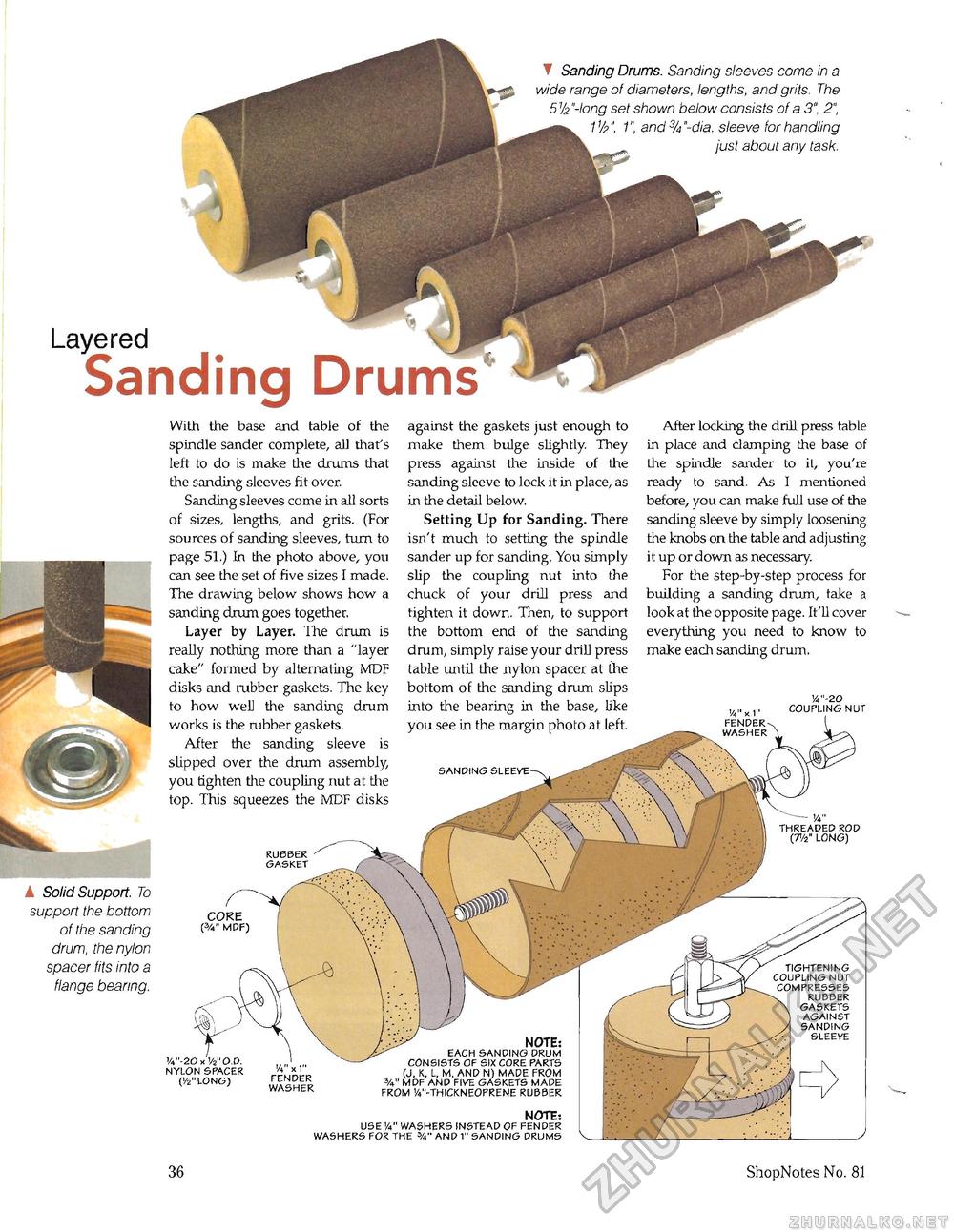

¥ Sanding Dnjms. Sanding sleeves come in a wide range of diameters, lengths, and grits. The 51k "-long set shown below consists of a 3° 2", IV2", 1", and3/4°-dia. sleeve for handling just about any task. Layered Sanding DrumsHi ▲ Solid Support. To support the bottom of the sanding drum, the nylon spacer fits into a flange bearing. With the base and table of the spindle sander complete, all that's left to do is make the drums that the sanding sleeves fit over. Sanding sleeves come in all sorts of sizes, lengths, and grits. (For sources of sanding sleeves, turn to page 51.) In the photo above, you can see the set of five sizes I made. The drawing below shows how a sanding drum goes together. Layer by Layer. The drum is really nothing more than a "layer cake" formed by alternating MDF disks and rubber gaskets. The key to how well the sanding drum works is the rubber gaskets. After the sanding sleeve is slipped over the drum assembly, you tighten the coupling nut at the top. This squeezes the MDF disks rubber GASKET against the gaskets just enough to make them bulge slightly. They press against the inside of the sanding sleeve to lock it in place, as in the detail below. Setting Up for Sanding. There isn't much to setting the spindle sander up for sanding. You simply slip the coupling nut into the chuck of your drill press and tighten it down. Then, to support the bottom end of the sanding drum, simply raise your drill press table until the nylon spacer at the bottom of the sanding drum slips into the bearing in the base, like you see in the margin photo at left. SANDING SLEEVE After locking the drill press table in place and clamping the base of the spindle sander to it, you're ready to sand. As I mentioned before, you can make full use of the sanding sleeve by simply loosening the knobs on the table and adjusting it up or down as necessary. For the step-by-step process for building a sanding drum, take a look at the opposite page. It'll cover everything you need to know to make each sanding drum. 'A" x 1" 'A"-20 coupling nut V*"-20 x Vz" O.O. NYLON SPACER 0/2" LONG) V4" x 1" FENDER WASHER NOTE: USE 'A" WASHERS INSTEAD OF FENDER WASHERS FOR THE V AND 1" SANDING DRUMS 36 ShopNotes No. 81 |