82 - The Complete Miter Saw Workstation, страница 50

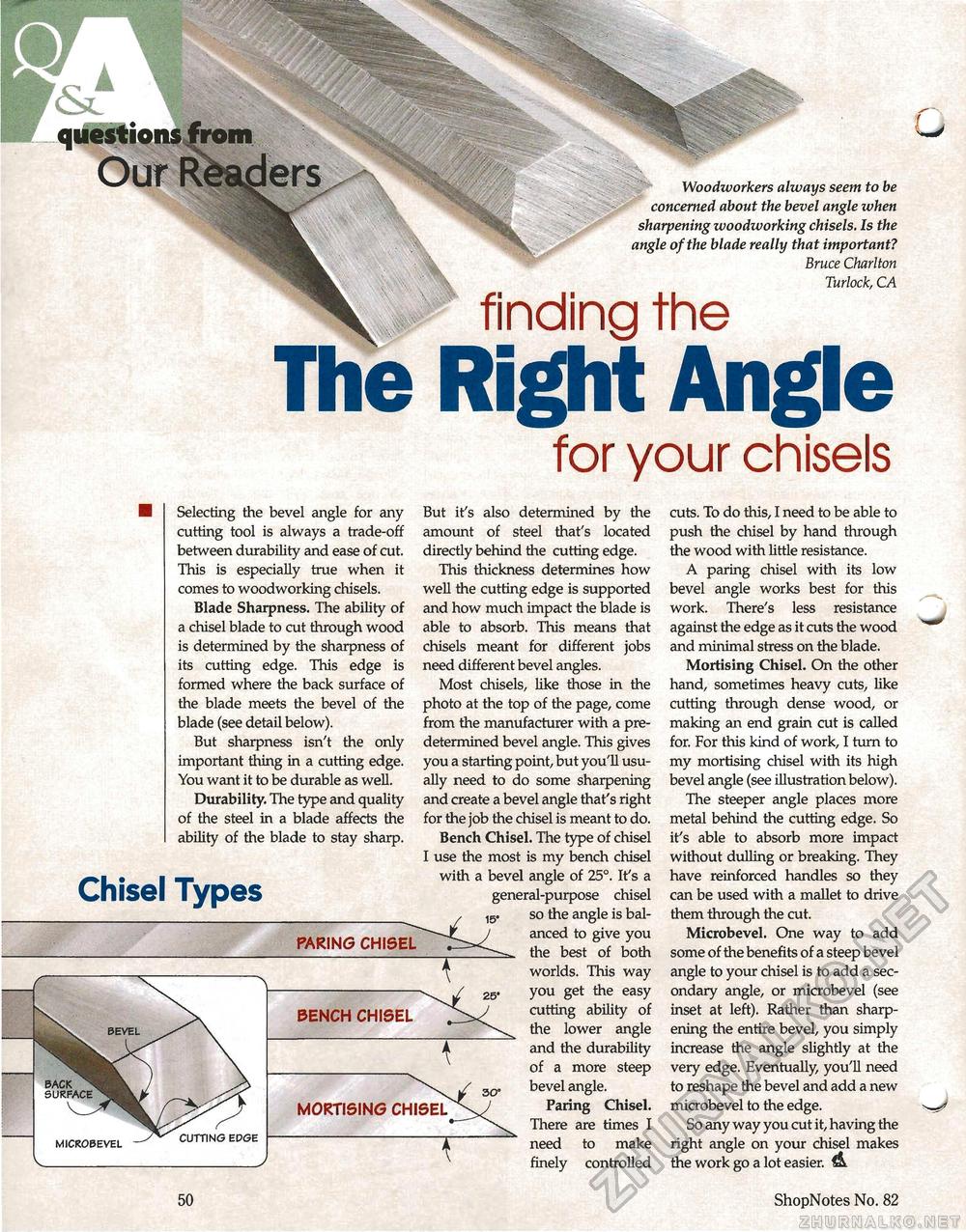

Woodworkers always seem to be concerned about the bevel angle when sharpening woodworking chisels. Is the angle of the blade really that important? Bruce Charlton Turlock, CA finding the The Right Anglefor your chisels Selecting the bevel angle for any cutting tool is always a trade-off between durability and ease of cut. This is especially true when it comes to woodworking chisels. Blade Sharpness. The ability of a chisel blade to cut through wood is determined by the sharpness of its cutting edge. This edge is formed where the back surface of the blade meets the bevel of the blade (see detail below). But sharpness isn't the only important thing in a cutting edge. You want it to be durable as well. Durability. The type and quality of the steel in a blade affects the ability of the blade to stay sharp. Chisel Types PARING CHISEL But it's also determined by the amount of steel that's located directly behind the cutting edge. This thickness determines how well the cutting edge is supported and how much impact the blade is able to absorb. This means that chisels meant for different jobs need different bevel angles. Most chisels, like those in the photo at the top of the page, come from the manufacturer with a predetermined bevel angle. This gives you a starting point, but you'll usually need to do some sharpening and create a bevel angle that's right for the job the chisel is meant to do. Bench Chisel. The type of chisel I use the most is my bench chisel with a bevel angle of 25°. If s a general-purpose chisel so the angle is balanced to give you the best of both worlds. This way you get the easy cutting ability of the lower angle A and the durability of a more steep bevel angle. Paring Chisel. There are times I need to make finely controlled cuts. To do this, I need to be able to push the chisel by hand through the wood with little resistance. A paring chisel with its low bevel angle works best for this work. There's less resistance against the edge as it cuts the wood and minimal stress on the blade. Mortising Chisel. On the other hand, sometimes heavy cuts, like cutting through dense wood, or making an end grain cut is called for. For this kind of work, I turn to my mortising chisel with its high bevel angle (see illustration below). The steeper angle places more metal behind the cutting edge. So it's able to absorb more impact without dulling or breaking. They have reinforced handles so they can be used with a mallet to drive them through the cut. Microbevel. One way to add some of the benefits of a steep bevel angle to your chisel is to add a secondary angle, or microbevel (see inset at left). Rather than sharpening the entire bevel, you simply increase the angle slightly at the very edge. Eventually, you'll need to reshape the bevel and add a new microbevel to the edge. So any way you cut it, having the right angle on your chisel makes the work go a lot easier. & 50 ShopNotes No. 82 |