83, страница 30

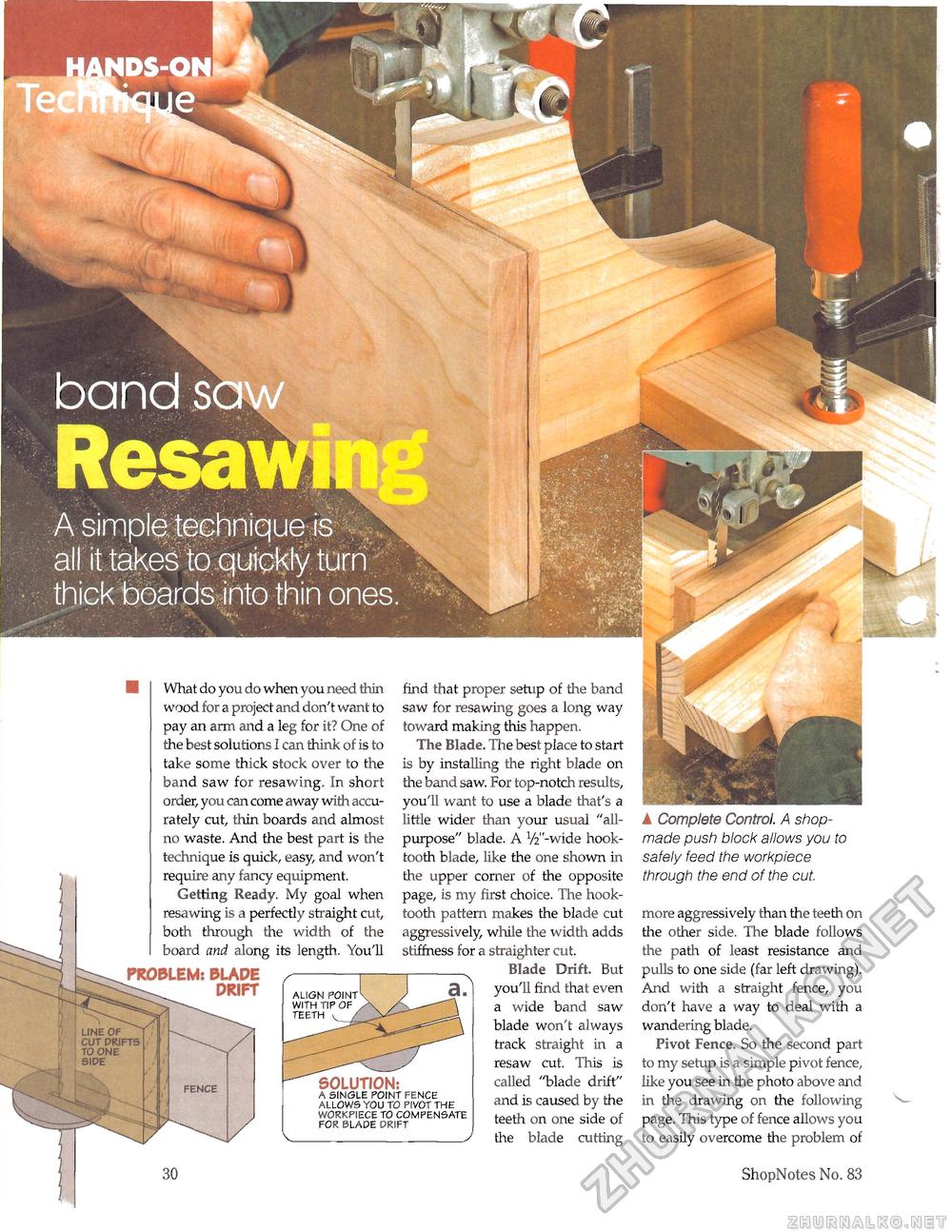

band s ResaA simple technique is all it takes to quickly turn thick boards into thin ones What do you do when you need thin wood for a project and don't want to pay an arm and a leg for it? One of the best solutions I can think of is to take some thick stock over to the band saw for resawing. In short order, you can come away with accurately cut, thin boards and almost no waste. And the best part is the technique is quick, easy, and won't require any fancy equipment. Getting Ready. My goal when resawing is a perfectly straight cut, both through the width of the board and along its length. You'll PROBLEM: BLADE DRIFT FENCE align with tip of teeth SOLUTION: a single point fence allows you to pivot the workpiece to compensate for blade drift _J find that proper setup of the band saw for resawing goes a long way toward making this happen. The Blade. The best place to start is by installing the right blade on the band saw. For top-notch results, you'll want to use a blade that's a little wider than your usual "all-purpose" blade. A VV'-wide hook-tooth blade, like the one shown in the upper corner of the opposite page, is my first choice. The hook-tooth pattern makes the blade cut aggressively, while the width adds stiffness for a straighter cut. Blade Drift. But you'll find that even a wide band saw blade won't always track straight in a resaw cut. This is called "blade drift" and is caused by the teeth on one side of the blade cutting A Complete Control. A shop-made push block allows you to safely feed the workpiece through the end of the cut. more aggressively than the teeth on the other side. The blade follows the path of least resistance and pulls to one side (far left drawing). And with a straight fence, you don't have a way to deal with a wandering blade. Pivot Fence. So the second part to my setup is a simple pivot fence, like you see in the photo above and in the drawing on the following page. This type of fence allows you to easily overcome the problem of 30 ShopNotes No. 83 |