85 - Router Table, страница 41

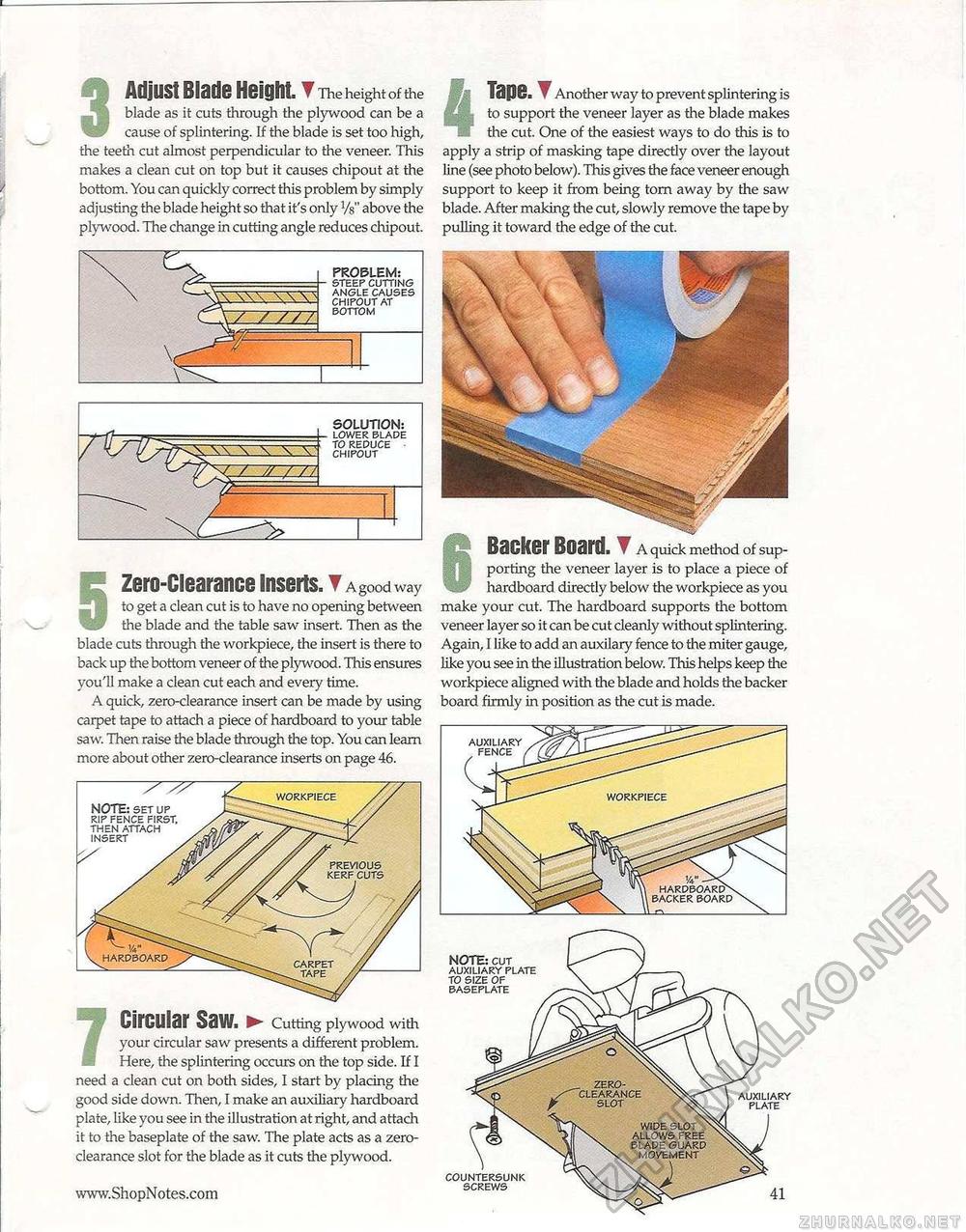

3 Adjust Blade Height Tn,e height 0f the blade as it cuts through the plywood can be a cause of splintering. If the blade is set too high, the teeth cut almost perpendicular to the veneer. This makes a clean cut on top but it causes chipout at the bottom. You can quickly correct this problem by simply adjusting the blade height so that it's only Vs" above the plywood. The change in cutting angle reduces chipout. 4 Tape. T Another way to prevent splintering is to support the veneer layer as the blade makes the cut. One of the easiest ways to do this is to apply a strip of masking tape directly over the layout line (see photo below). This gives the face veneer enough support to keep it from being torn away by tire saw blade. After making tire cut, slowly remove the tape by pulling it toward the edge of the cut. PROBLEM: STEEP CUTTING ANGLE CAUSES CHIPOUT AT BOTTOM SOLUTION: LOWER BLADE TO REDUCE CHIPOUT — 5 Zero-Clearance Inserts. T Ag00d way to get a clean cut is to have no opening between the blade and the table saw insert. Then as the blade cuts through the workpiece, the insert is there to back up the bottom veneer of the plywood. This ensures you'll make a clean cut each and every time. A quick, zero-clearance insert can be made by using carpet tape to attach a piece of hardboard to your table saw. Then raise the blade through tire top. You can learn more about other zero-clearance inserts on page 46. AUXILIARY FENCE WORKPIECE HARDBOARD^ BACKER BOARD NOTE: SET UP RIP FENCE FIRST. THEN ATTACH INSERT 7 Circular Saw. ► Cutting plywood with your circular saw presents a different problem. Here, the splintering occurs on the top side. If I need a clean cut on both sides, I start by placing the good side down. Then, I make an auxiliary hardboard plate, like you see in the illustration at right, and attach it to tire baseplate of the saw. The plate acts as a zero-clearance slot for the blade as it cuts the plywood. Backer Board. T A quick method of supporting the veneer layer is to place a piece of hardboard directly below the workpiece as you make your cut. The hardboard supports the bottom veneer layer so it can be cut cleanly without splintering. Again, I like to add an auxilary fence to the miter gauge, like you see in the illustration below. This helps keep tire workpiece aligned with the blade and holds the backer board firmly in position as the cut is made. NOTE: CUT AUXILIARY PLATE TO SIZE OF BASEPLATE COUNTERSUNK SCREWS AUXILIARY PLATE |