85 - Router Table, страница 39

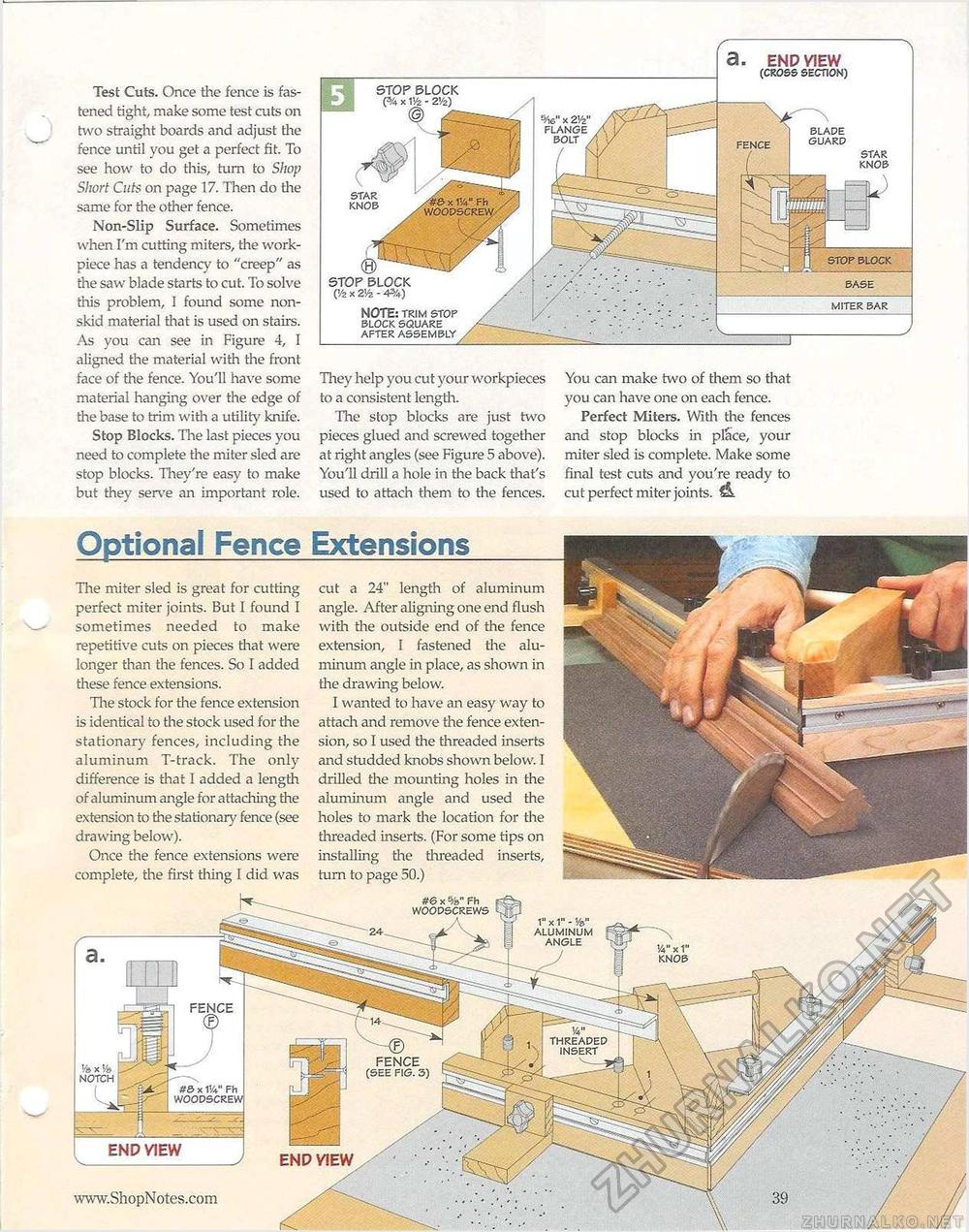

Test Cuts. Once the fence is fastened tight make some test cuts on two straight boards and adjust the fence until you get a perfect fit. To see how to do this, turn to Shop Short Cuts on page 17. Then do the same for the other fence. Non-Slip Surface. Sometimes when I'm cutting miters, the work-piece has a tendency to "creep" as the saw blade starts to cut. To solve this problem, I found some non-skid material that is used on stairs. As you can see in Figure 4, I aligned the material with the front face of the fence. You'll have some material hanging over the edge of the base to trim with a utility knife. Stop Blocks. The last pieces you need to complete the miter sled are stop blocks. They're easy to make but they serve an important role. They help you cut your workpieces to a consistent length. The stop blocks are just two pieces glued and screwed together at right angles (see Figure 5 above). You'll drill a hole in the back that's used to attach them to the fences. You can make two of them so that you can have one on each fence. Perfect Miters. With the fences and stop blocks in place, your miter sled is complete. Make some final test cuts and you're ready to cut perfect miter joints. & STAR KNOB base MITER BAR STOP BLOCK ('/2 x 2Vt - 4%) NOTE: TRIM STOP BLOCK SQUARE AFTER ASSEMBLY stop block a. END VIEW (cross section) Optional Fence Extensions The miter sled is great for cutting perfect miter joints. But I found I sometimes needed to make repetitive cuts on pieces that were longer than the fences. So I added these fence extensions. The stock for the fence extension is identical to the stock used for the stationary fences, including the aluminum T-track. The only difference is that I added a length of aluminum angle for attaching the extension to the stationary fence (see drawing below). Once the fence extensions were complete, the first thing I did was cut a 24" length of aluminum angle. After aligning one end flush with the outside end of the fence extension, I fastened the aluminum angle in place, as shown in the drawing below. I wanted to have an easy way to attach and remove the fence extension, so I used the threaded inserts and studded knobs shown below. I drilled tire mounting holes in the aluminum angle and used the holes to mark the location for the threaded inserts. (For some tips on installing tire threaded inserts, turn to page 50.) END VIEW FENCE (SEE FIG. 3) END VIEW Vs. x'/» NOTCH #0 x W Fh WOODSCREW |