86, страница 26

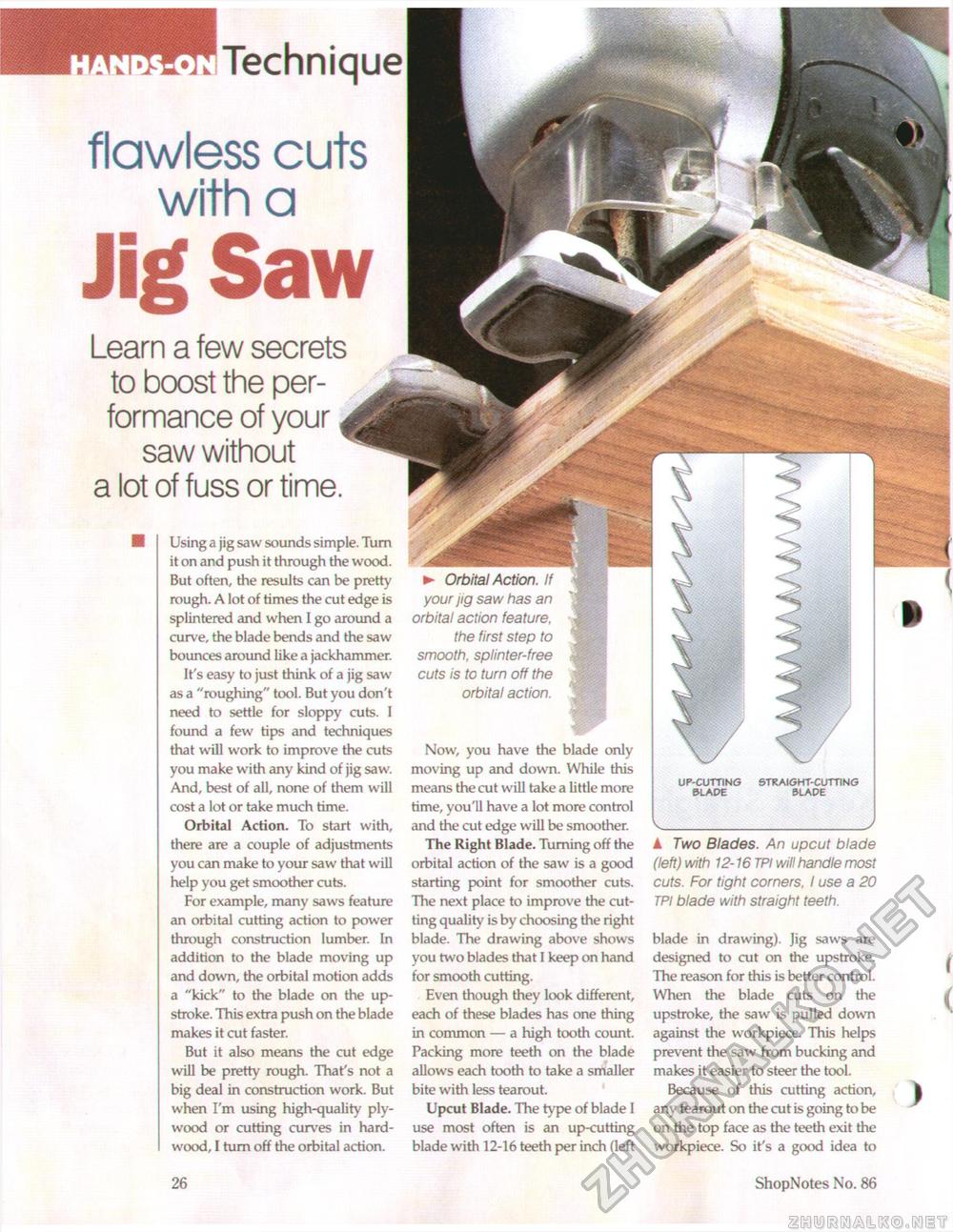

^Technique flawless cuts with a Jig Saw A Two Blades. An upcut blade (left) with 12-16 TPl will handle most cuts. For tight corners, I use a 20 TPl blade with straight teeth. blade in drawing). Jig saws are designed to cut on the upstroke. The reason for this is better control. When the blade cuts on the upstroke, the saw is pulled down against the workpiece. This helps prevent the saw from bucking and makes it easier to steer the tool. Because of this cutting action, any tearout on the cut is going to be on the top face as the teeth exit the workpiece. So it's a good idea to Learn a few secrets to boost the performance of your saw without a lot of fuss or time. ( Using a jig saw sounds simple. Turn it on and push it through the wood. But often, the results can be pretty rough. A lot of times the cut edge is splintered and when I go around a curve, the blade bends and the saw bounces around like a jackhammer. It's easy to just think of a jig saw as a "roughing" tool. But you don't need to settle for sloppy cuts. I found a few tips and techniques that will work to improve the cuts you make with any kind of jig saw. And, best of all, none of them will cost a lot or take much time. Orbital Action. To start with, there are a couple of adjustments you can make to your saw that will help you get smoother cuts. For example, many saws feature an orbital cutting action to power through construction lumber. In addition to the blade moving up and down, the orbital motion adds a "kick" to the blade on the upstroke. This extra push on the blade makes it cut faster. But it also means the cut edge will be pretty rough. That's not a big deal in construction work. But when I'm using high-quality plywood or cutting curves in hardwood, I turn off the orbital action. up-cutting straight-cutting &lade blade ► Orbital Action. If your jig saw has an orbital action feature, the first step to smooth, splinter-free cuts is to turn off the orbital action. Now, you have the blade only moving up and down. While this means the cut will take a little more time, you'll have a lot more control and the cut edge will be smoother. The Right Blade. Turning off the orbital action of the saw is a good starting point for smoother cuts. The next place to improve the cutting quality is by choosing the right blade. The drawing above shows you two blades that I keep on hand for smooth cutting. Even though they look different, each of these blades has one thing in common — a high tooth count. Packing more teeth on the blade allows each tooth to take a smaller bite with less tearout. Upcut Blade. The type of blade I use most often is an up-cutting blade with 12-16 teeth per inch (left 26 ShopNotes No. 86 |