87, страница 8

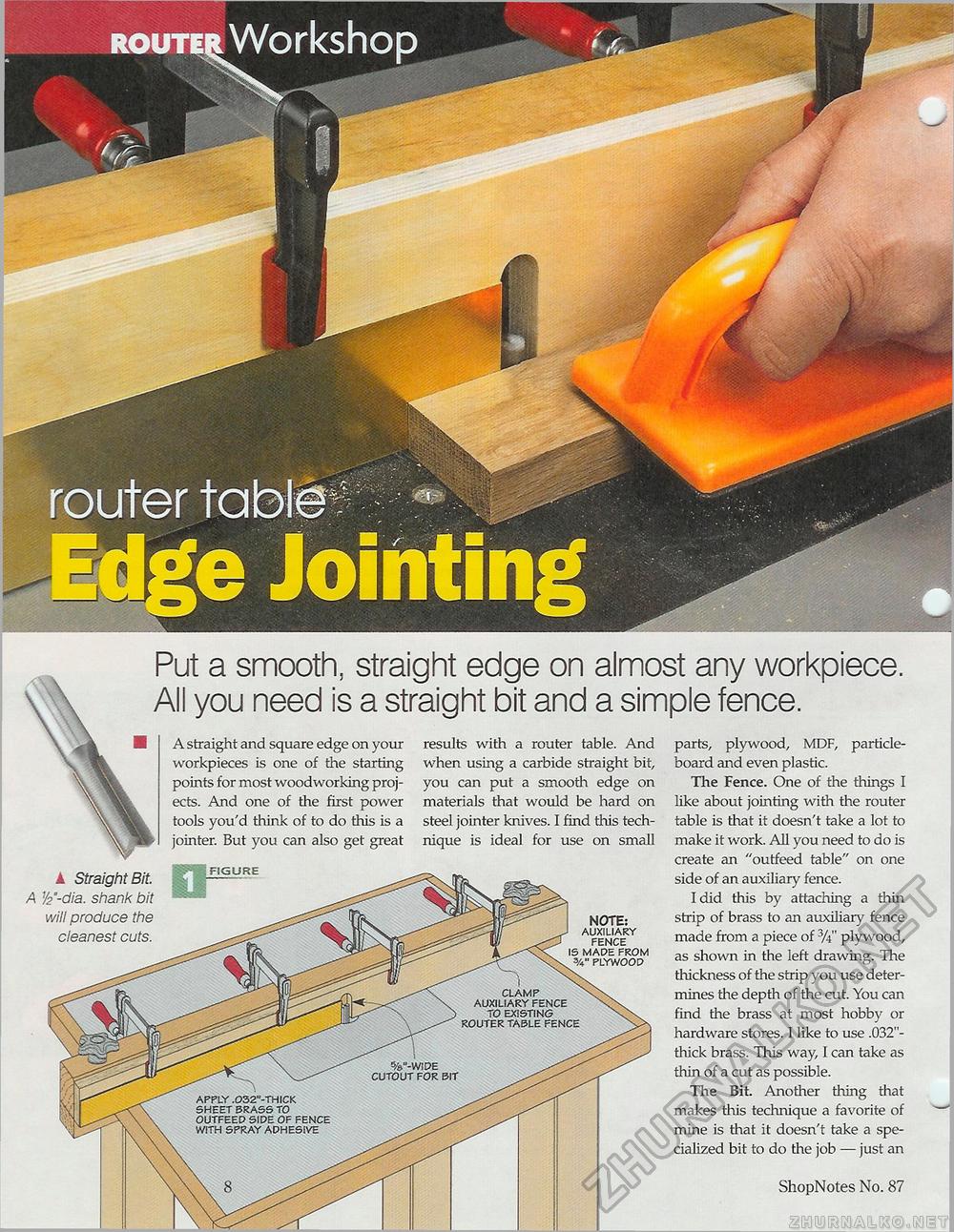

Workshop CLAMP AUXILIARY FENCE TO EXISTING ROUTER TABLE FENCE %"-WIDE CUTOUT FOR BIT APPLY .032"-THICK SHEET BRASS TO OUTFEED SIDE OF FENCE WITH SPRAY ADHESIVE Put a smooth, straight edge on almost any workpiece. All you need is a straight bit and a simple fence. parts, plywood, MDF, particle-board and even plastic. The Fence. One of the things I like about jointing with the router table is that it doesn't take a lot to make it work. All you need to do is create an "outfeed table" on one side of an auxiliary fence. I did this by attaching a thin strip of brass to an auxiliary fence made from a piece of %" plywood, as shown in the left drawing. The thickness of the strip you use determines the depth of the cut. You can find the brass at most hobby or hardware stores. I like to use .032"-thick brass. This way, I can take as thin of a cut as possible. The Bit. Another thing that makes this technique a favorite of mine is that it doesn't take a specialized bit to do the job — just an 90 ShoDNotes No. 87 A straight and square edge on your workpieces is one of the starting points for most woodworking projects. And one of the first power tools you'd think of to do this is a jointer. But you can also get great ▲ Straight Bit. A fe'-dia. shank bit will produce the cleanest cuts. results with a router table. And when using a carbide straight bit, you can put a smooth edge on materials that would be hard on steel jointer knives. I find this technique is ideal for use on small NOTE: AUXILIARY FENCE IS MADE FROM %" PLYWOOD FIGURE |