93, страница 13

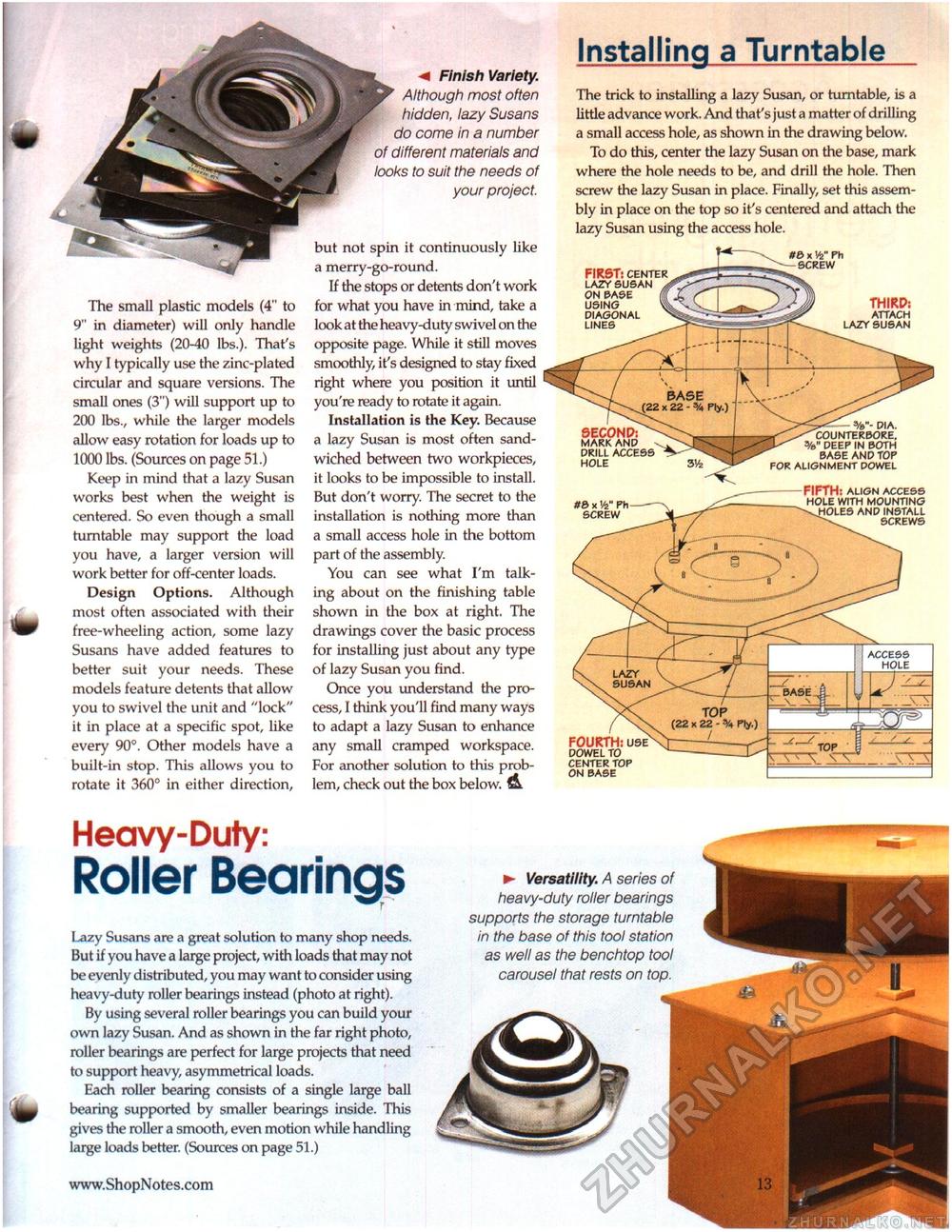

tar Heavy-Duty: Roller Bearings Lazy Susans are a great solution to many shop needs. But if you have a large project, with loads that may not be evenly distributed, you may want to consider using heavy-duty roller bearings instead (photo at right). By using several roller bearings you can build your own lazy Susan. And as shown in the far right photo, roller bearings are perfect for large projects that need to support heavy, asymmetrical loads. Each roller bearing consists of a single large ball bearing supported by smaller bearings inside. This gives the roller a smooth, even motion while handling large loads better. (Sources on page 51.) M Finish Variety. Although most often hidden, lazy Susans do come in a number of different materials and looks to suit the needs of your project. but not spin it continuously like a merry-go-round. If the stops or detents don't work for what you have in mind, take a look at the heavy-duty swivel on the opposite page. While it still moves smoothly, it's designed to stay fixed right where you position it until you're ready to rotate it again. Installation is the Key. Because a lazy Susan is most often sandwiched between two workpieces, it looks to be impossible to install. But don't worry. The secret to the installation is nothing more than a small access hole in the bottom part of the assembly. You can see what I'm talking about on the finishing table shown in the box at right. The drawings cover the basic process for installing just about any type of lazy Susan you find. Once you understand the process, 1 think you'll find many ways to adapt a lazy Susan to enhance any small cramped workspace. For another solution to this problem, check out the box below. & The small plastic models (4" to 9" in diameter) will only handle light weights (20-40 lbs.). That's why I typically use the zinc-plated circular and square versions. The small ones (3") will support up to 200 lbs., while the larger models allow easy rotation for loads up to 1000 lbs. (Sources on page 51.) Keep in mind that a lazy Susan works best when the weight is centered. So even though a small turntable may support the load you have, a larger version will work better for off-center loads. Design Options. Although most often associated with their free-wheeling action, some lazy Susans have added features to better suit your needs. These models feature detents that allow you to swivel the unit and "lock" it in place at a specific spot, like every 90°. Other models have a built-in stop. This allows you to rotate it 360° in either direction, Installing a Turntable ——■■■■■■"■—■ ^—- The trick to installing a lazy Susan, or turntable, is a little advance work. And that's just a matter of drilling a small access hole, as shown in the drawing below. To do this, center the lazy Susan on the base, mark where the hole needs to be, and drill the hole. Then screw the lazy Susan in place. Finally, set this assembly in place on the top so it's centered and attach the lazy Susan using the access hole. FIRST: center lazy susan on base using diagonal lines #0 x W Ph screw third: attach lazy susan SECOND: mark and drill access hole »e> x W screw DIA. COUNTERBORE. DEEP IN BOTH BASE AND TOP FOR ALIGNMENT DOWEL align access mounting and install screws FOURTH: use dowel to center top on base ■fl^HHHMHMMMNRMi ► Versatility. A series of heavy-duty roller bearings supports the storage turntable in the base of this tool station as well as the benchtop tool carousel that rests on top. |