93, страница 34

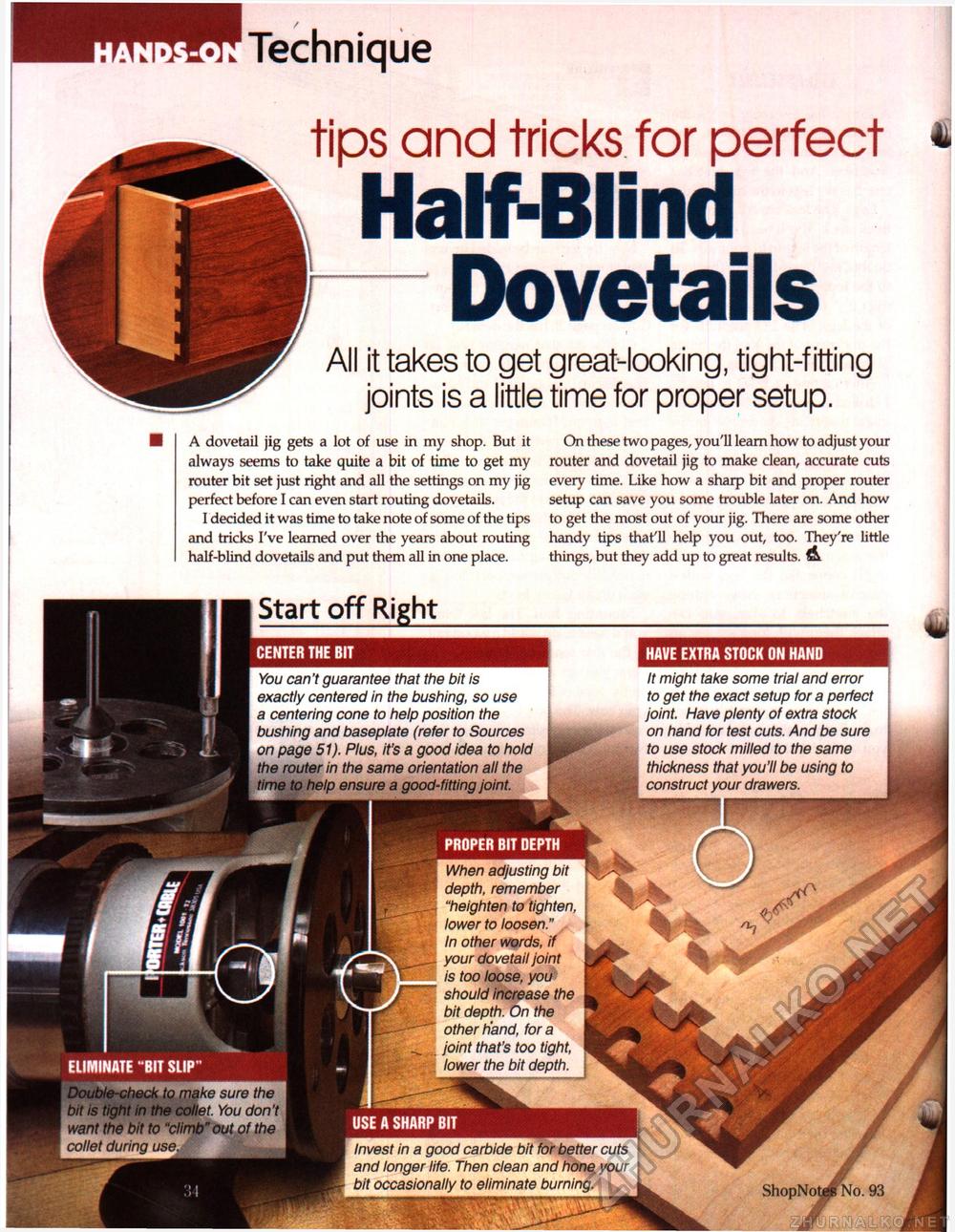

■Technique A dovetail jig gets a lot of use in my shop. But it always seems to take quite a bit of time to get my router bit set just right and all the settings on my jig perfect before I can even start routing dovetails. I decided it was time to take note of some of the tips and tricks I've learned over the years about routing half-blind dovetails and put them all in one place. On these two pages, you'll learn how to adjust your router and dovetail jig to make clean, accurate cuts every time. Like how a sharp bit and proper router setup can save you some trouble later on. And how to get the most out of your jig. There are some other handy tips that'll help you out, too. They're little things, but they add up to great results. A tips and tricks for perfectHalf-Blind DovetailsAll it takes to get great-looking, tight-fitting joints is a little time for proper setup. HAVE EXTRA STOCK ON HAND USE A SHARP BIT Start off Right It might take some trial and error to get the exact setup for a perfect joint. Have plenty of extra stock on hand for test cuts. And be sure to use stock milled to the same thickness that you'll be using to construct your drawers. You can't guarantee that the bit is exactly centered in the bushing, so use a centering cone to help position the bushing and baseplate (refer to Sources on page 51). Plus, it's a good idea to hold the router in the same orientation all the time to help ensure a good-fitting joint. When adjusting bit depth, remember "heighten to tighten, lower to loosen." In other words, if your dovetail joint is too loose, you should increase the bit depth. On the other hand, for a joint that's too tight, lower the bit depth. Double-check to make sure the bit is tight in the collet. You don't want the bit to *climb" out of the collet during use. Invest in a good carbide bit for better cuts and longer life. Then clean and hone your bit occasionally to eliminate burning. ShopNotgjB No. 93 |