95, страница 27

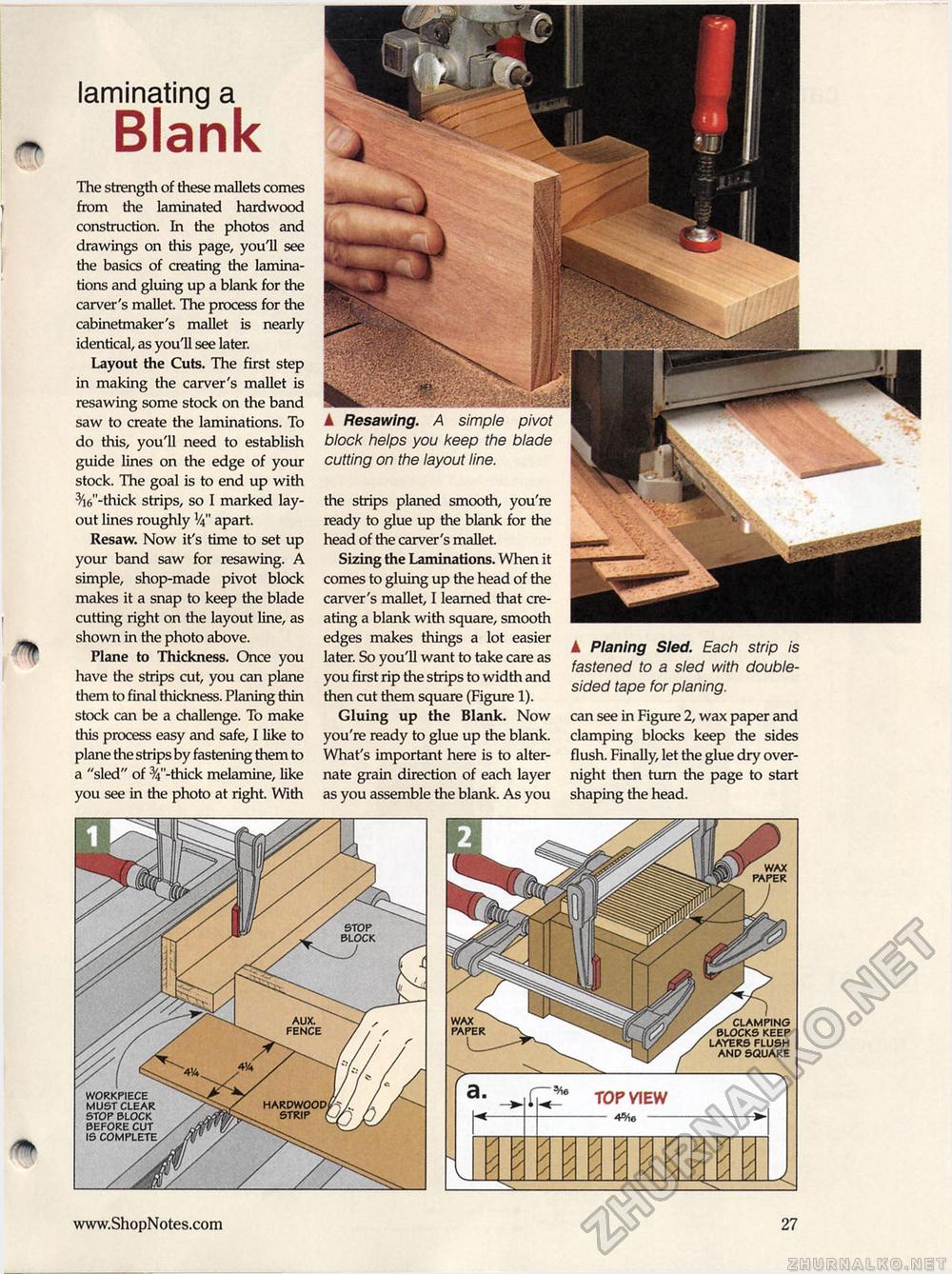

laminating a Blank The strength of these mallets comes from the laminated hardwood construction. In the photos and drawings on this page, you'll see the basics of creating the laminations and gluing up a blank for the carver's mallet. The process for the cabinetmaker's mallet is nearly identical, as you'll see later. Layout the Cuts. The first step in making the carver's mallet is resawing some stock on the band saw to create the laminations. To do this, you'll need to establish guide lines on the edge of your stock. The goal is to end up with 3/i6"-thick strips, so I marked layout lines roughly V4" apart. Resaw. Now it's time to set up your band saw for resawing. A simple, shop-made pivot block makes it a snap to keep the blade cutting right on the layout line, as shown in the photo above. Plane to Thickness. Once you have the strips cut, you can plane them to final thickness. Planing thin stock can be a challenge. To make this process easy and safe, I like to plane the strips by fastening them to a "sled" of %"-thick melamine, like you see in the photo at right. With ▲ Resawing. A simple pivot block helps you keep the blade cutting on the layout line. the strips planed smooth, you're ready to glue up the blank for the head of the carver's mallet. Sizing the Laminations. When it comes to gluing up the head of the carver's mallet, I learned that creating a blank with square, smooth edges makes things a lot easier later. So you'll want to take care as you first rip the strips to width and then cut them square (Figure 1). Gluing up the Blank. Now you're ready to glue up the blank. What's important here is to alternate grain direction of each layer as you assemble the blank. As you ▲ Planing Sled. Each strip is fastened to a sled with double-sided tape for planing. can see in Figure 2, wax paper and clamping blocks keep the sides flush. Finally, let the glue dry overnight then turn the page to start shaping the head. STOP BLOCK WORKPIECE MUST CLEAR STOP BLOCK BEFORE CUT IS COMPLETE HARDWOOD: STRIP ( CLAMPING BLOCKS KEEP LAYERS FLUSH AND SQUARE TOP VIEW — 4^8 — |