95, страница 50

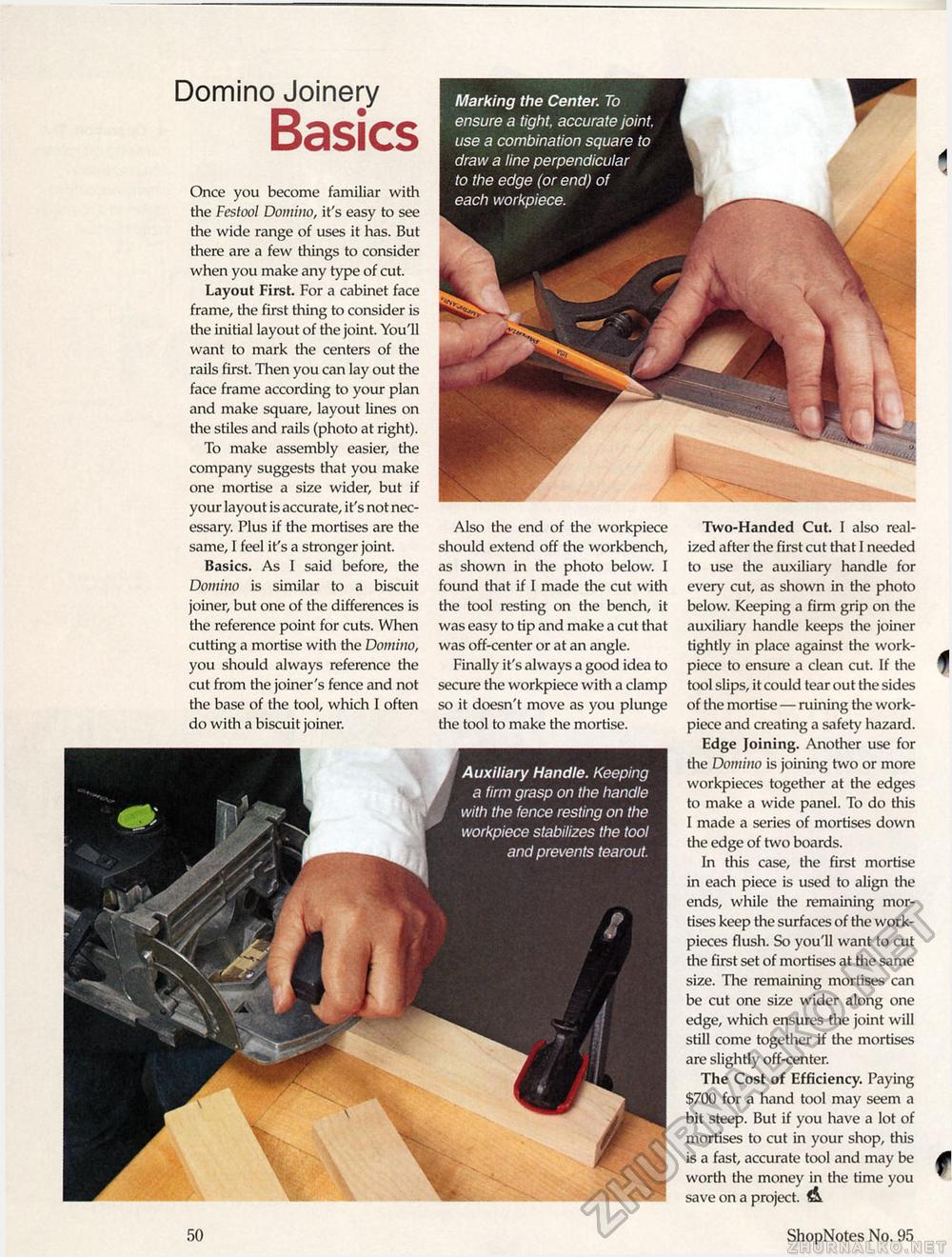

Marking the Center. To ensure a tight, accurate joint, use a combination square to draw a line perpendicular to the edge (or end) of each workpiece. Also the end of the workpiece should extend off the workbench, as shown in the photo below. I found that if I made the cut with the tool resting on the bench, it was easy to tip and make a cut that was off-center or at an angle. Finally it's always a good idea to secure the workpiece with a clamp so it doesn't move as you plunge the tool to make the mortise. Auxiliary Handle. Keeping a firm grasp on the handle with the fence resting on the workpiece stabilizes the tool and prevents tearout. Domino Joinery Basics Once you become familiar with the Festool Domino, it's easy to see the wide range of uses it has. But there are a few things to consider when you make any type of cut. Layout First. For a cabinet face frame, the first thing to consider is the initial layout of the joint. You'll want to mark the centers of the rails first. Then you can lay out the face frame according to your plan and make square, layout lines on the stiles and rails (photo at right). To make assembly easier, the company suggests that you make one mortise a size wider, but if your layout is accurate, it's not necessary. Plus if the mortises are the same, I feel it's a stronger joint. Basics. As I said before, the Domino is similar to a biscuit joiner, but one of the differences is the reference point for cuts. When cutting a mortise with the Domino, you should always reference the cut from the joiner's fence and not the base of the tool, which I often do with a biscuit joiner. Two-Handed Cut. I also realized after the first cut that I needed to use the auxiliary handle for every cut, as shown in the photo below. Keeping a firm grip on the auxiliary handle keeps the joiner tightly in place against the work-piece to ensure a clean cut. If the tool slips, it could tear out the sides of the mortise — ruining the work-piece and creating a safety hazard. Edge Joining. Another use for the Domino is joining two or more workpieces together at the edges to make a wide panel. To do this I made a series of mortises down the edge of two boards. In this case, the first mortise in each piece is used to align the ends, while the remaining mortises keep the surfaces of the work-pieces flush. So you'll want to cut the first set of mortises at the same size. The remaining mortises can be cut one size wider along one edge, which ensures the joint will still come together if the mortises are slightly off-center. The Cost of Efficiency. Paying $700 for a hand tool may seem a bit steep. But if you have a lot of mortises to cut in your shop, this is a fast, accurate tool and may be worth the money in the time you save on a project. A 50 ShopNotes No. 95 |