95, страница 47

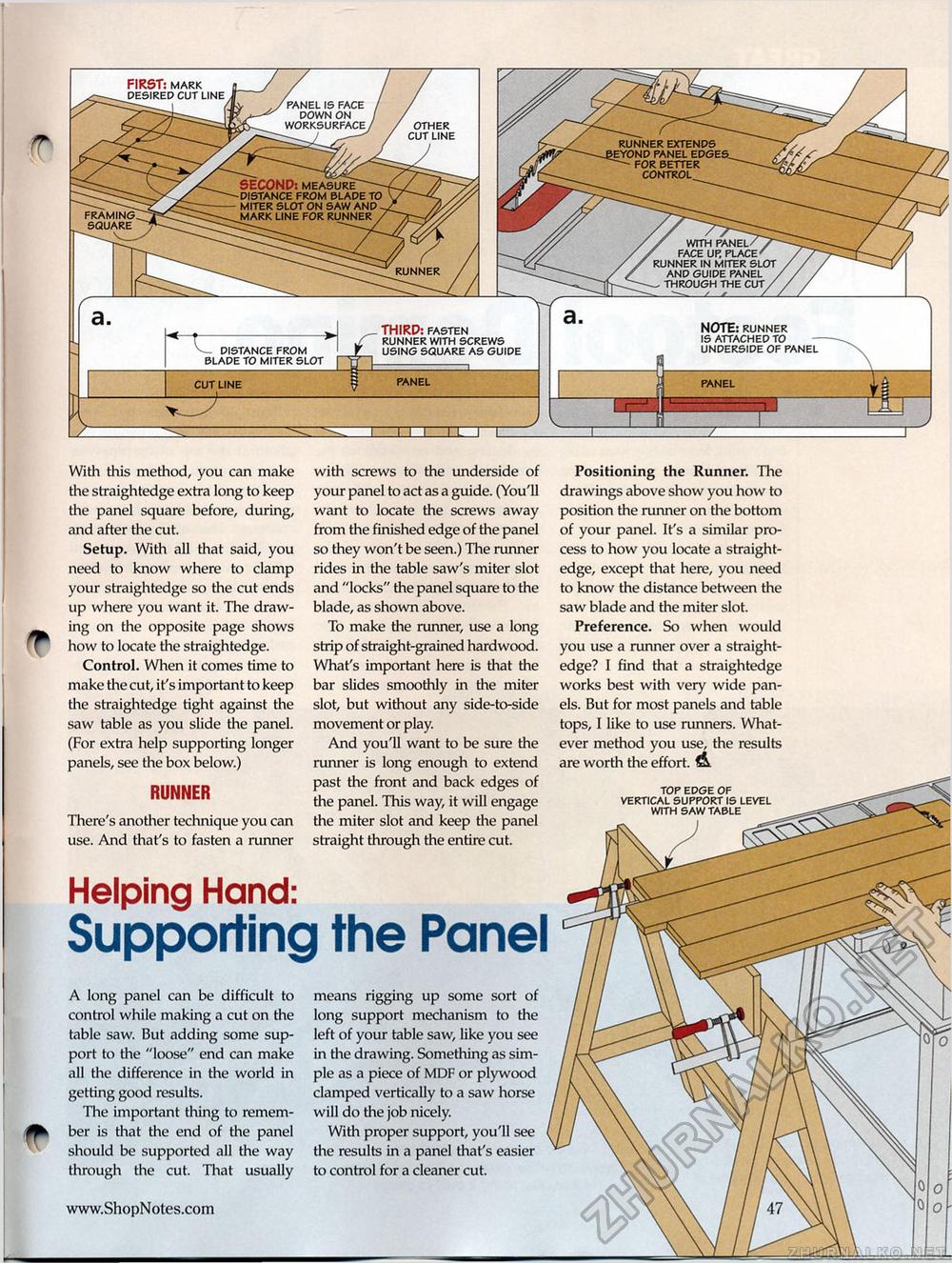

T With this method, you can make the straightedge extra long to keep the panel square before, during, and after the cut. Setup. With all that said, you need to know where to clamp your straightedge so the cut ends up where you want it. The drawing on the opposite page shows how to locate the straightedge. Control. When it comes time to make the cut, it's important to keep the straightedge tight against the saw table as you slide the panel. (For extra help supporting longer panels, see the box below.) RUNNER There's another technique you can use. And that's to fasten a runner with screws to the underside of your panel to act as a guide. (You'll want to locate the screws away from the finished edge of the panel so they won't be seen.) The runner rides in the table saw's miter slot and "locks" the panel square to the blade, as shown above. To make the runner, use a long strip of straight-grained hardwood. What's important here is that the bar slides smoothly in the miter slot, but without any side-to-side movement or play. And you'll want to be sure the runner is long enough to extend past the front and back edges of the panel. This way, it will engage the miter slot and keep the panel straight through the entire cut. Helping Hand: Supporting the Panel A long panel can be difficult to control while making a cut on the table saw. But adding some support to the "loose" end can make all the difference in the world in getting good results. The important thing to remem-ittk ber is that the end of the panel should be supported all the way through the cut. That usually means rigging up some sort of long support mechanism to the left of your table saw, like you see in the drawing. Something as simple as a piece of MDF or plywood clamped vertically to a saw horse will do the job nicely. With proper support, you'll see the results in a panel that's easier to control for a cleaner cut. Positioning the Runner. The drawings above show you how to position the runner on the bottom of your panel. It's a similar process to how you locate a straightedge, except that here, you need to know the distance between the saw blade and the miter slot. Preference. So when would you use a runner over a straightedge? I find that a straightedge works best with very wide panels. But for most panels and table tops, I like to use runners. Whatever method you use, the results are worth the effort. A top edge of vertical support is level with saw table panel is face down on worksurface runner extends eyond panel edge —- for better control SECOND: measur[T~—- distance from blade to miter slot on saw and -mark line for runner / framing square / with panel/ f face uf! place' runner in miter slot and guide panel , _ through the cut/ runner FIRST: mark desired cut line . other cut line distance from blade to miter slot _ THIRD: fasten x runner with screws v using square as guide cut line panel NOTE: runner is attached to underside of |