95, страница 44

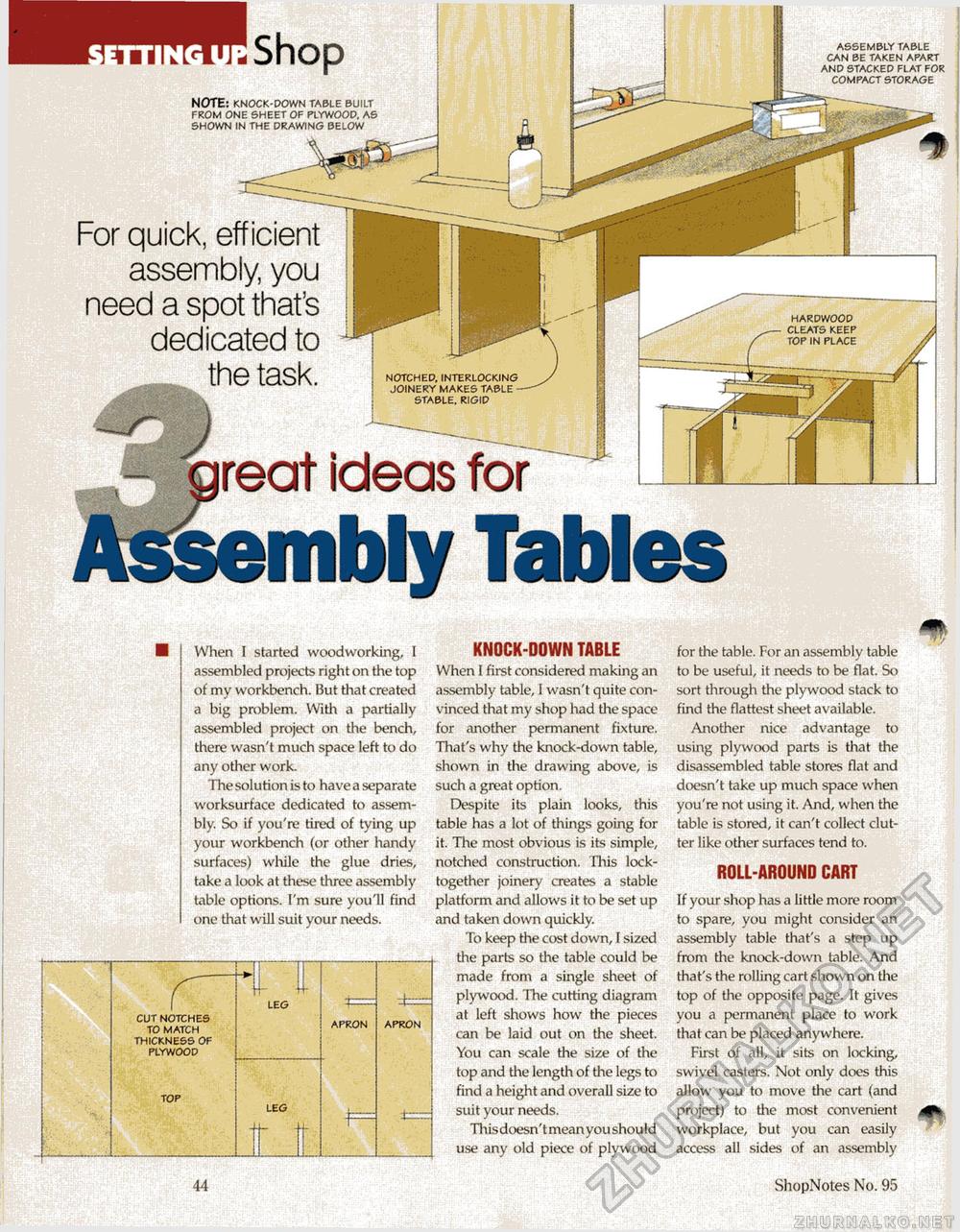

NOTE: KNOCK-DOWN TABLE BUILT FROM ONE SHEET OF PLYWOOD, AS SHOWN IN THE DRAWING BELOW ASSEMBLY TABLE CAN BE TAKEN APART AND STACKED FLAT FOR COMPACT STORAGE APRON TO MATCH THICKNESS OF PLYWOOD t= APRON For quick, effic assembly, you need a spot that's dedicated to HARDWOOD the task NOTCHED, INTERLOCKING JOINERY MAKES TABLE STABLE. RIGID ,- gre Asse reat ideas formbly Tables44 ShopNotes No. 95 for the table. For an assembly table to be useful, it needs to be flat. So sort through the plywood stack to find the flattest sheet available. Another nice advantage to using plywood parts is that the disassembled table stores flat and doesn't take up much space when you're not using it. And, when the table is stored, it can't collect clutter like other surfaces tend to. ROLL-AROUND CART If your shop has a little more room to spare, you might consider an assembly table that's a step up from the knock-down table. And that's the rolling cart shown on the top of the opposite page. It gives you a permanent place to work that can be placed anywhere. First of all, it sits on locking, swivel casters. Not only does this allow you to move the cart (and project) to the most convenient workplace, but you can easily access all sides of an assembly When I started woodworking, I assembled projects right on the top of my workbench. But that created a big problem. With a partially assembled project on the bench, there wasn't much space left to do any other work. The solution is to have a separate worksurface dedicated to assembly. So if you're tired of tying up your workbench (or other handy surfaces) while the glue dries, take a look at these three assembly table options. I'm sure you'll find one that will suit your needs. KNOCK DOWN TABLE When 1 first considered making an assembly table, I wasn't quite convinced that my shop had the space for another permanent fixture. That's why the knock-down table, shown in the drawing above, is such a great option. Despite its plain looks, this table has a lot of things going for it. The most obvious is its simple, notched construction. This lock-together joinery creates a stable platform and allows it to be set up and taken down quickly. To keep the cost down, I sized the parts so the table could be made from a single sheet of plywood. The cutting diagram at left shows how the pieces can be laid out on the sheet. You can scale the size of the top and the length of the legs to find a height and overall size to suit your needs. This doesn't mean you shou Id use any old piece of plywood |