95, страница 46

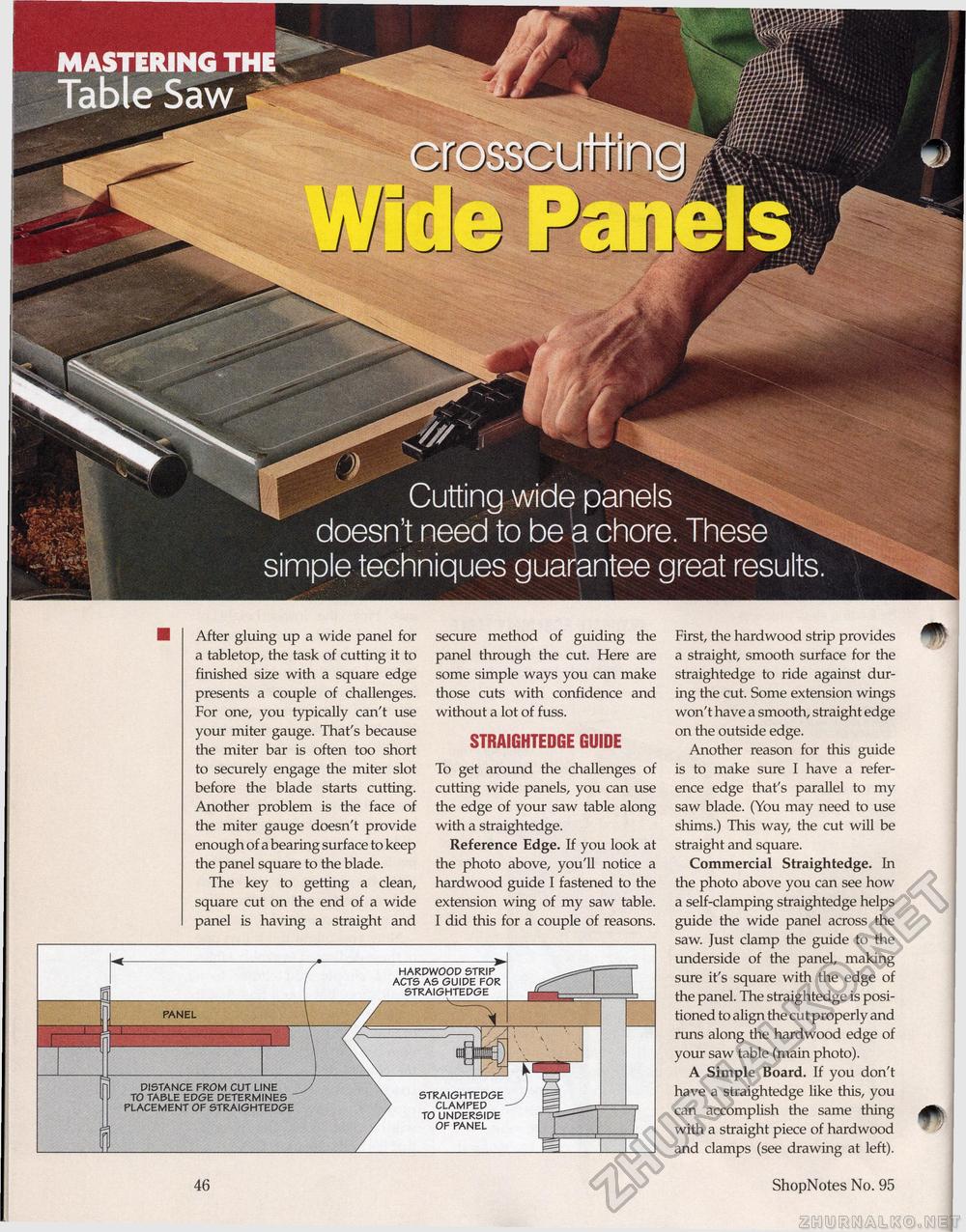

wmfii MASTERING THE Table Saw m Cutting wide panels doesn't need to be a chore. These simple techniques guarantee great results After gluing up a wide panel for a tabletop, the task of cutting it to finished size with a square edge presents a couple of challenges. For one, you typically can't use your miter gauge. That's because the miter bar is often too short to securely engage the miter slot before the blade starts cutting. Another problem is the face of the miter gauge doesn't provide enough of a bearing surface to keep the panel square to the blade. The key to getting a clean, square cut on the end of a wide panel is having a straight and secure method of guiding the panel through the cut. Here are some simple ways you can make those cuts with confidence and without a lot of fuss. STRAIGHTEDGE GUIDE To get around the challenges of cutting wide panels, you can use the edge of your saw table along with a straightedge. Reference Edge. If you look at the photo above, you'll notice a hardwood guide I fastened to the extension wing of my saw table. I did this for a couple of reasons. First, the hardwood strip provides a straight, smooth surface for the straightedge to ride against during the cut. Some extension wings won't have a smooth, straight edge on the outside edge. Another reason for this guide is to make sure I have a reference edge that's parallel to my saw blade. (You may need to use shims.) This way, the cut will be straight and square. Commercial Straightedge. In the photo above you can see how a self-clamping straightedge helps guide the wide panel across the saw. Just clamp the guide to the underside of the panel, making sure it's square with the edge of the panel. The straightedge is positioned to align the cut properly and runs along the hardwood edge of your saw table (main photo). A Simple Board. If you don't have a straightedge like this, you can accomplish the same thing with a straight piece of hardwood and clamps (see drawing at left). 46 ShopNotes No. 95 |