95, страница 8

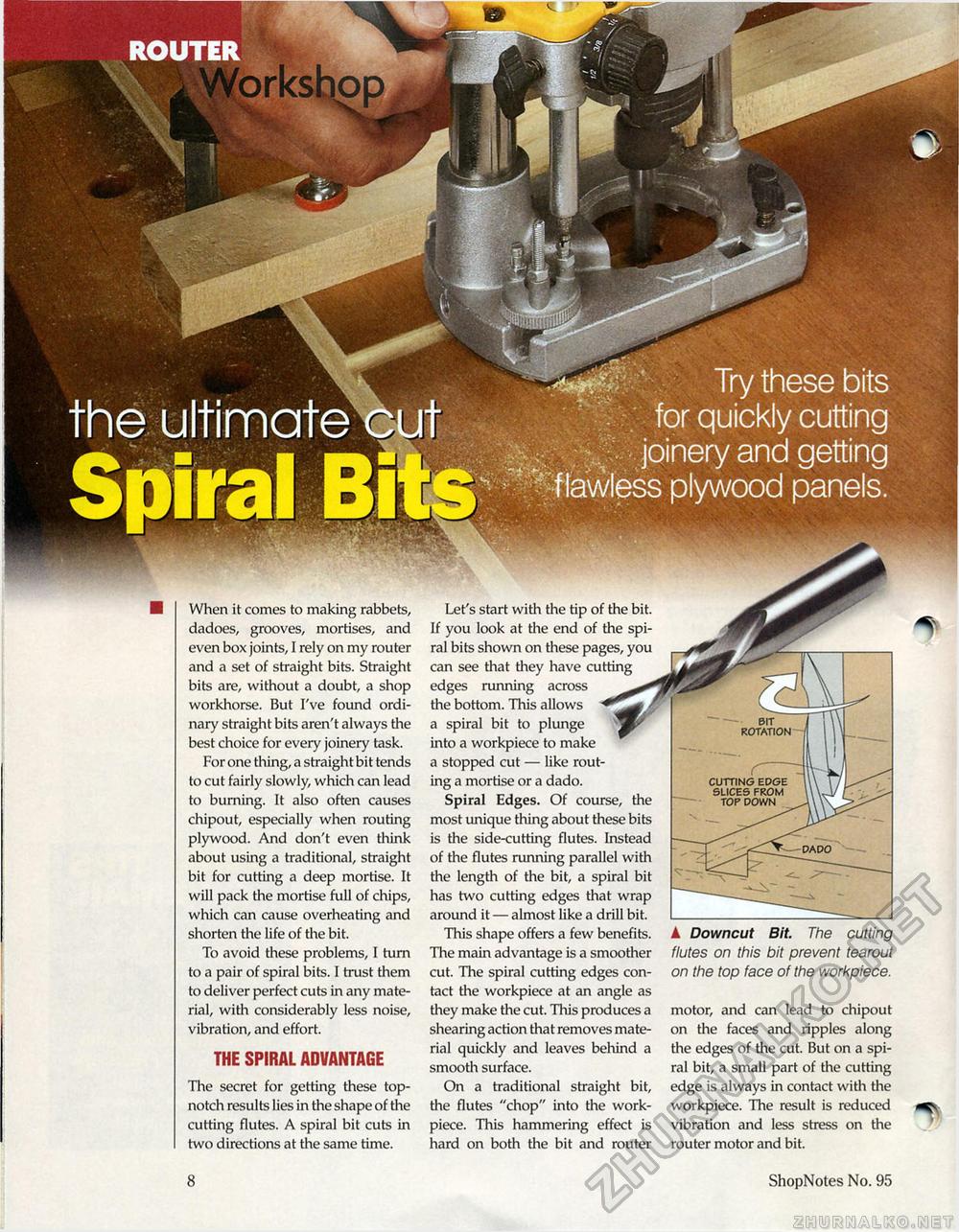

bit rotation dado v*wag*} Try these bits for quickly cutting joinery and getting flawless plywood panels. ►rkshop ▲ Downcut Bit. The cutting flutes on this bit prevent tearout on the top face of the workpiece. motor, and can lead to chipout on the faces and ripples along the edges of the cut. But on a spiral bit, a small part of the cutting edge is always in contact with the workpiece. The result is reduced vibration and less stress on the router motor and bit. When it comes to making rabbets, dadoes, grooves, mortises, and even box joints, I rely on my router and a set of straight bits. Straight bits are, without a doubt, a shop workhorse. But I've found ordinary straight bits aren't always the best choice for every joinery task. For one thing, a straight bit tends to cut fairly slowly, which can lead to burning. It also often causes chipout, especially when routing plywood. And don't even think about using a traditional, straight bit for cutting a deep mortise. It will pack the mortise full of chips, which can cause overheating and shorten the life of the bit. To avoid these problems, I turn to a pair of spiral bits. I trust them to deliver perfect cuts in any material, with considerably less noise, vibration, and effort. THE SPIRAL ADVANTAGE The secret for getting these top-notch results lies in the shape of the cutting flutes. A spiral bit cuts in two directions at the same time. Let's start with the tip of the bit. If you look at the end of the spiral bits shown on these pages, you can see that they have cutting edges running across the bottom. This allows a spiral bit to plunge into a workpiece to make a stopped cut — like routing a mortise or a dado. Spiral Edges. Of course, the most unique thing about these bits is the side-cutting flutes. Instead of the flutes running parallel with the length of the bit, a spiral bit has two cutting edges that wrap around it — almost like a drill bit. This shape offers a few benefits. The main advantage is a smoother cut. The spiral cutting edges contact the workpiece at an angle as they make the cut. This produces a shearing action that removes material quickly and leaves behind a smooth surface. On a traditional straight bit, the flutes "chop" into the work-piece. This hammering effect is hard on both the bit and router cutting edge slices from top down - 8 ShopNotes No. 95 |