Woodworker's Journal 1981-5-6, страница 32

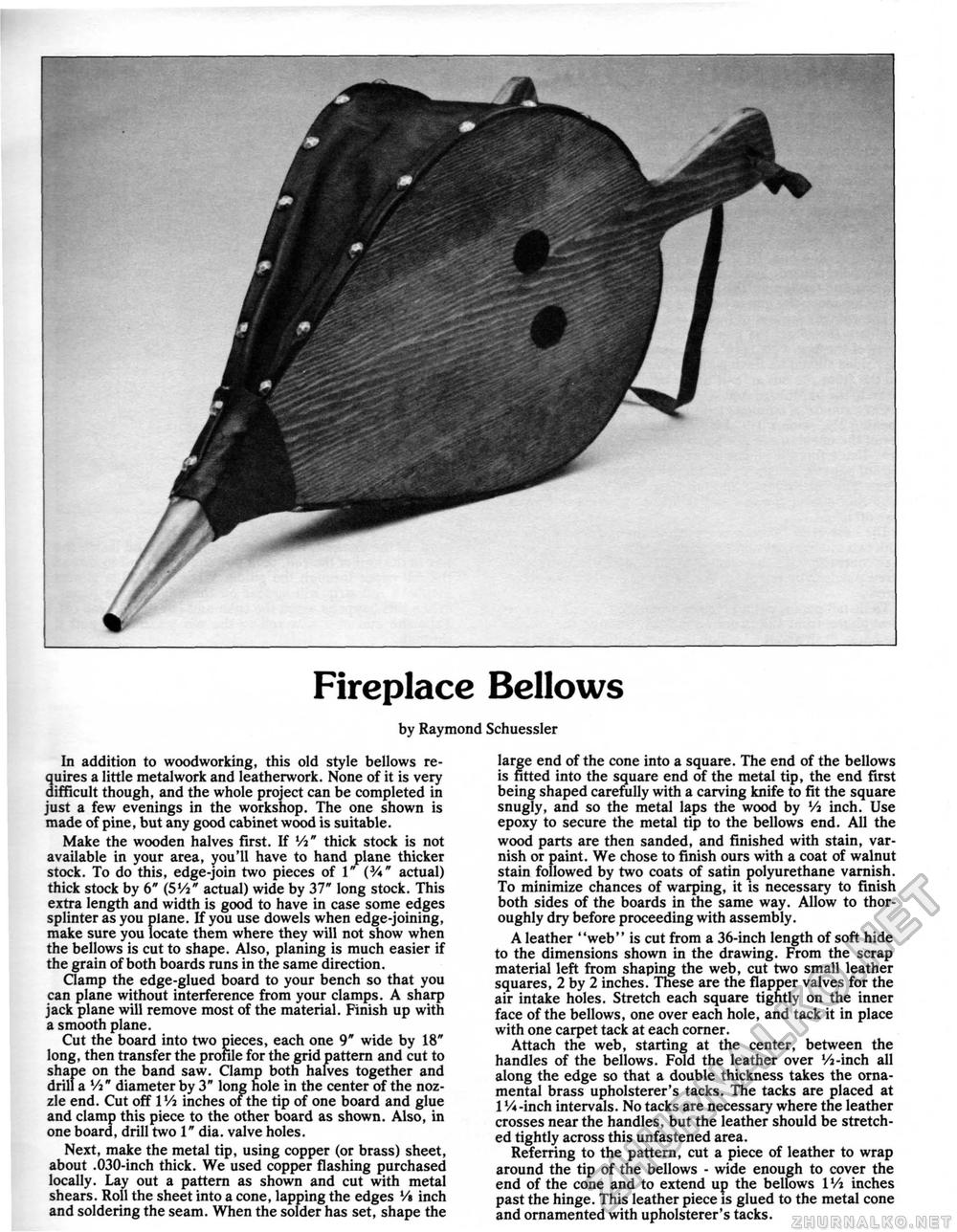

Fireplace Bellows by Raymond Schuessler In addition to woodworking, this old style bellows requires a little metalwork and leatherwork. None of it is very difficult though, and the whole project can be completed in just a few evenings in the workshop. The one shown is made of pine, but any good cabinet wood is suitable. Make the wooden halves first. If Vi" thick stock is not available in your area, you'll have to hand plane thicker stock. To do this, edge-join two pieces of 1" (3A" actual) thick stock by 6" (5'/j" actual) wide by 37" long stock. This extra length and width is good to have in case some edges splinter as you plane. If you use dowels when edge-joining, make sure you locate them where they will not show when the bellows is cut to shape. Also, planing is much easier if the grain of both boards runs in the same direction. Clamp the edge-glued board to your bench so that you can plane without interference from your clamps. A sharp jack plane will remove most of the material. Finish up with a smooth plane. Cut the board into two pieces, each one 9" wide by 18" long, then transfer the profile for the grid pattern and cut to shape on the band saw. Clamp both halves together and drill a Vi" diameter by 3" long hole in the center of the nozzle end. Cut off l'/i inches of the tip of one board and glue and clamp this piece to the other board as shown. Also, in one board, drill two 1" dia. valve holes. Next, make the metal tip, using copper (or brass) sheet, about .030-inch thick. We used copper flashing purchased locally. Lay out a pattern as shown and cut with metal shears. Roll the sheet into a cone, lapping the edges Vi inch and soldering the seam. When the solder has set, shape the large end of the cone into a square. The end of the bellows is fitted into the square end of the metal tip, the end first being shaped carefully with a carving knife to fit the square snugly, and so the metal laps the wood by Vi inch. Use epoxy to secure the metal tip to the bellows end. All the wood parts are then sanded, and finished with stain, varnish or paint. We chose to finish ours with a coat of walnut stain followed by two coats of satin polyurethane varnish. To minimize chances of warping, it is necessary to finish both sides of the boards in the same way. Allow to thoroughly dry before proceeding with assembly. A leather "web" is cut from a 36-inch length of soft hide to the dimensions shown in the drawing. From the scrap material left from shaping the web, cut two small leather squares, 2 by 2 inches. These are the flapper valves for the air intake holes. Stretch each square tightly on the inner face of the bellows, one over each hole, and tack it in place with one carpet tack at each corner. Attach the web, starting at the center, between the handles of the bellows. Fold the leather over Vi-inch all along the edge so that a double thickness takes the ornamental brass upholsterer's tacks. The tacks are placed at 1 Vi-inch intervals. No tacks are necessary where the leather crosses near the handles, but the leather should be stretched tightly across this unfastened area. Referring to the pattern, cut a piece of leather to wrap around the tip of the bellows - wide enough to cover the end of the cone and to extend up the bellows V/i inches past the hinge. This leather piece is glued to the metal cone and ornamented with upholsterer's tacks. |