Woodworker's Journal 1981-5-6, страница 34

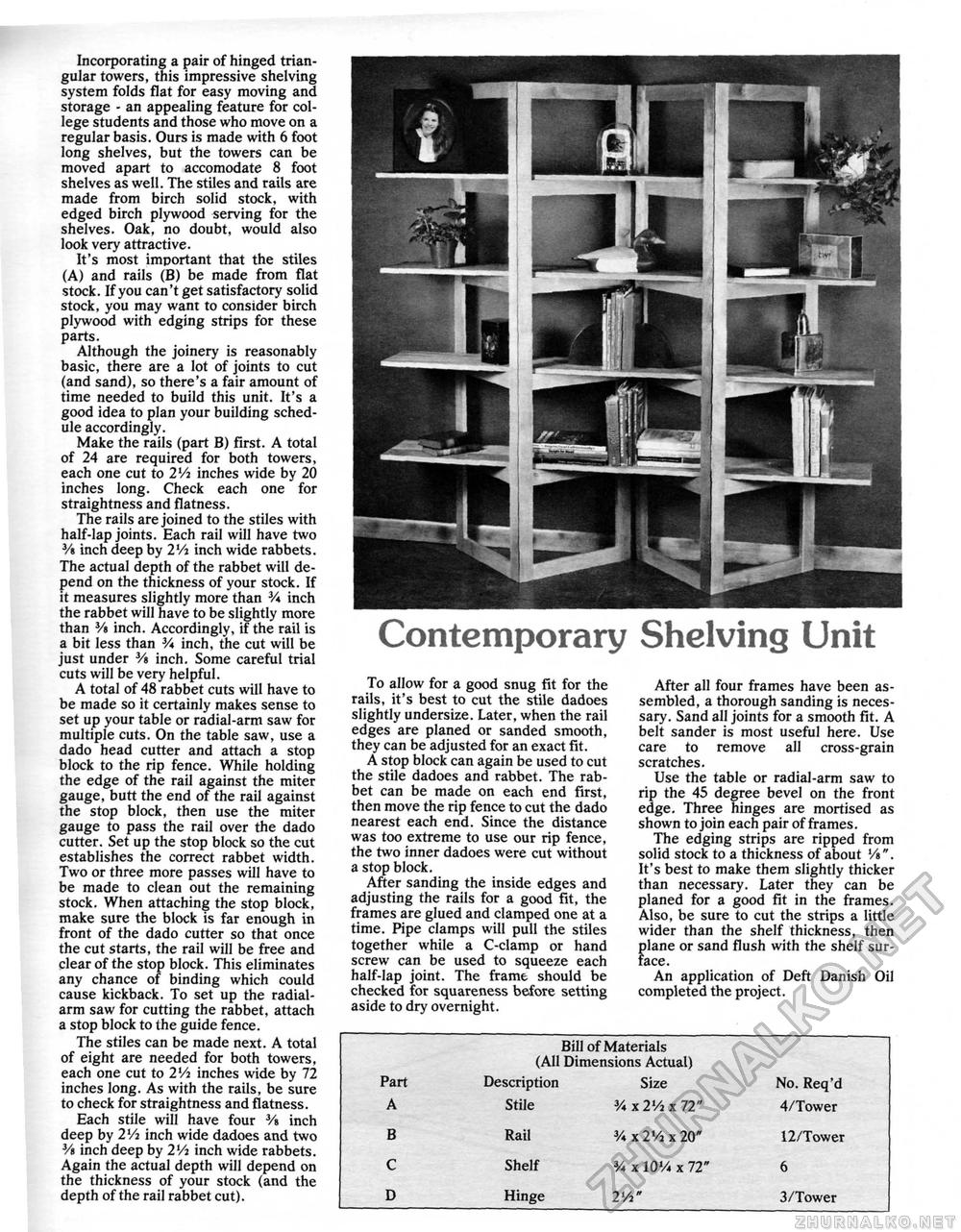

Contemporary Shelving Unit Incorporating a pair of hinged triangular towers, this impressive shelving system folds flat for easy moving and storage - an appealing feature for college students and those who move on a regular basis. Ours is made with 6 foot long shelves, but the towers can be moved apart to accomodate 8 foot shelves as well. The stiles and rails are made from birch solid stock, with edged birch plywood serving for the shelves. Oak, no doubt, would also look very attractive. It's most important that the stiles (A) and rails (B) be made from flat stock. If you can't get satisfactory solid stock, you may want to consider birch plywood with edging strips for these parts. Although the joinery is reasonably basic, there are a lot of joints to cut (and sand), so there's a fair amount of time needed to build this unit. It's a good idea to plan your building schedule accordingly. Make the rails (part B) first. A total of 24 are required for both towers, each one cut to 2Vi inches wide by 20 inches long. Check each one for straightness and flatness. The rails are joined to the stiles with half-lap joints. Each rail will have two Vt inch deep by 2Vi inch wide rabbets. The actual depth of the rabbet will depend on the thickness of your stock. If it measures slightly more than 3A inch the rabbet will have to be slightly more than Vt inch. Accordingly, if the rail is a bit less than V* inch, the cut will be just under 3/> inch. Some careful trial cuts will be very helpful. A total of 48 rabbet cuts will have to be made so it certainly makes sense to set up your table or radial-arm saw for multiple cuts. On the table saw, use a dado head cutter and attach a stop block to the rip fence. While holding the edge of the rail against the miter gauge, butt the end of the rail against the stop block, then use the miter gauge to pass the rail over the dado cutter. Set up the stop block so the cut establishes the correct rabbet width. Two or three more passes will have to be made to clean out the remaining stock. When attaching the stop block, make sure the block is far enough in front of the dado cutter so that once the cut starts, the rail will be free and clear of the stop block. This eliminates any chance of binding which could cause kickback. To set up the radial-arm saw for cutting the rabbet, attach a stop block to the guide fence. The stiles can be made next. A total of eight are needed for both towers, each one cut to 2Vi inches wide by 72 inches long. As with the rails, be sure to check for straightness and flatness. Each stile will have four V» inch deep by 2Vt inch wide dadoes and two Vs inch deep by 2Vj inch wide rabbets. Again the actual depth will depend on the thickness of your stock (and the depth of the rail rabbet cut). To allow for a good snug fit for the rails, it's best to cut the stile dadoes slightly undersize. Later, when the rail edges are planed or sanded smooth, they can be adjusted for an exact fit. A stop block can again be used to cut the stile dadoes and rabbet. The rabbet can be made on each end first, then move the rip fence to cut the dado nearest each end. Since the distance was too extreme to use our rip fence, the two inner dadoes were cut without a stop block. After sanding the inside edges and adjusting the rails for a good fit, the frames are glued and clamped one at a time. Pipe clamps will pull the stiles together while a C-clamp or hand screw can be used to squeeze each half-lap joint. The frame should be checked for squareness before setting aside to dry overnight. After all four frames have been assembled, a thorough sanding is necessary. Sand all joints for a smooth fit. A belt sander is most useful here. Use care to remove all cross-grain scratches. Use the table or radial-arm saw to rip the 45 degree bevel on the front edge. Three hinges are mortised as shown to join each pair of frames. The edging strips are ripped from solid stock to a thickness of about Vs". It's best to make them slightly thicker than necessary. Later they can be planed for a good fit in the frames. Also, be sure to cut the strips a little wider than the shelf thickness, then plane or sand flush with the shelf surface. An application of Deft Danish Oil completed the project. Bill of Materials (All Dimensions Actual) Bill of Materials (All Dimensions Actual)

|