Woodworker's Journal 1983-7-1, страница 42

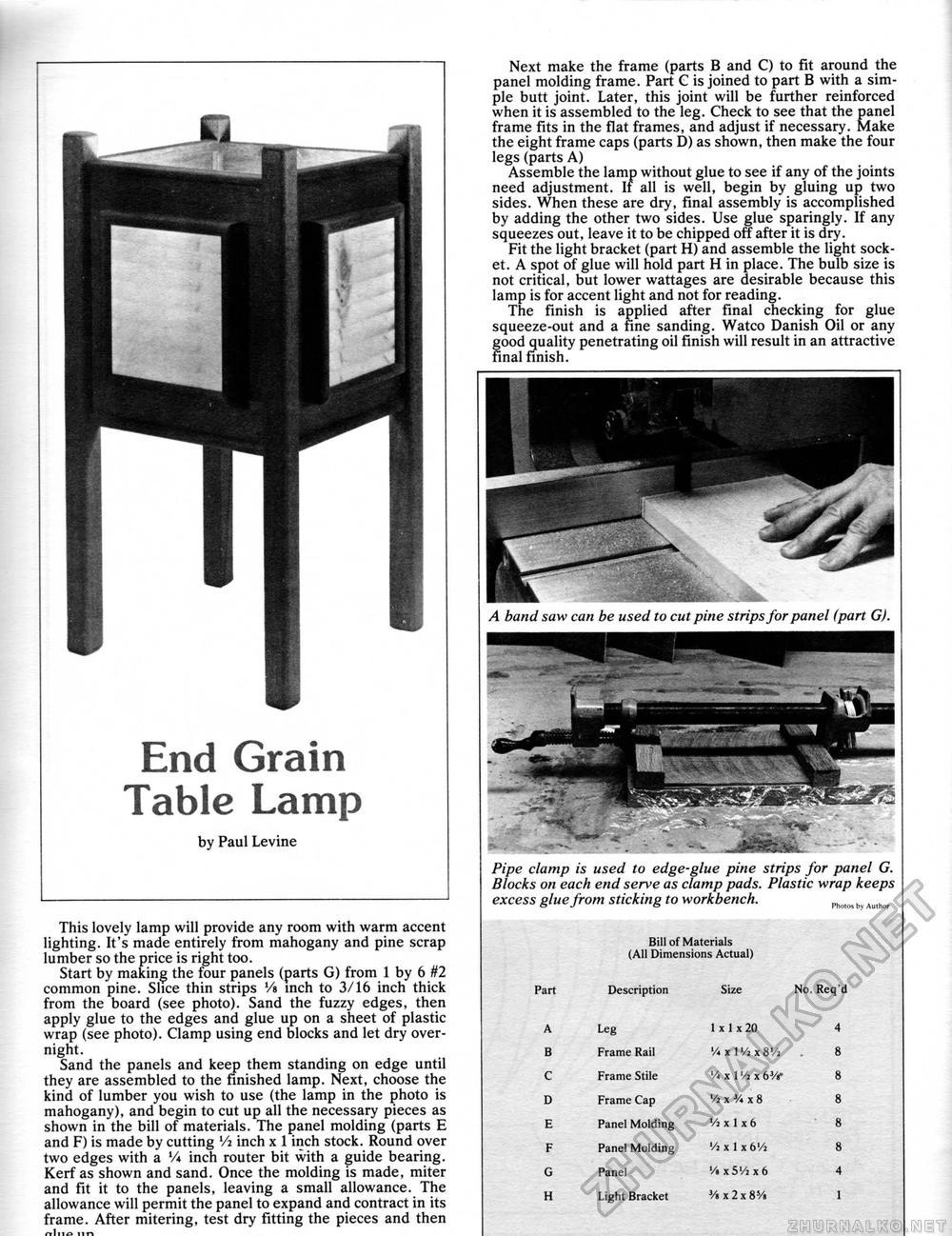

End Grain Table Lampby Paul Levine This lovely lamp will provide any room with warm accent lighting. It's made entirely from mahogany and pine scrap lumber so the price is right too. Start by making the four panels (parts G) from 1 by 6 #2 common pine. Slice thin strips V» inch to 3/16 inch thick from the board (see photo). Sand the fuzzy edges, then apply glue to the edges and glue up on a sheet of plastic wrap (see photo). Clamp using end blocks and let dry overnight. Sand the panels and keep them standing on edge until they are assembled to the finished lamp. Next, choose the kind of lumber you wish to use (the lamp in the photo is mahogany), and begin to cut up all the necessary pieces as shown in the bill of materials. The panel molding (parts E and F) is made by cutting Vi inch x 1 inch stock. Round over two edges with a '/* inch router bit with a guide bearing. Kerf as shown and sand. Once the molding is made, miter and fit it to the panels, leaving a small allowance. The allowance will permit the panel to expand and contract in its frame. After mitering, test dry fitting the pieces and then Next make the frame (parts B and C) to fit around the panel molding frame. Part C is joined to part B with a simple butt joint. Later, this joint will be further reinforced when it is assembled to the leg. Check to see that the panel frame fits in the flat frames, and adjust if necessary. Make the eight frame caps (parts D) as shown, then make the four legs (parts A) Assemble the lamp without glue to see if any of the joints need adjustment. If all is well, begin by gluing up two sides. When these are dry, final assembly is accomplished by adding the other two sides. Use glue sparingly. If any squeezes out, leave it to be chipped off after it is dry. Fit the light bracket (part H) and assemble the light socket. A spot of glue will hold part H in place. The bulb size is not critical, but lower wattages are desirable because this lamp is for accent light and not for reading. The finish is applied after final checking for glue squeeze-out and a fine sanding. Watco Danish Oil or any good quality penetrating oil finish will result in an attractive final finish. n hp nn A band saw can be used to cut pine strips for panel (part G). Pipe clamp is used to edge-glue pine strips for panel G. Blocks on each end serve as clamp pads. Plastic wrap keeps excess glue from sticking to workbench. Phoiro by Author Bill of Materials (All Dimensions Actual) Bill of Materials (All Dimensions Actual)

|