Woodworker's Journal 1983-7-1, страница 46

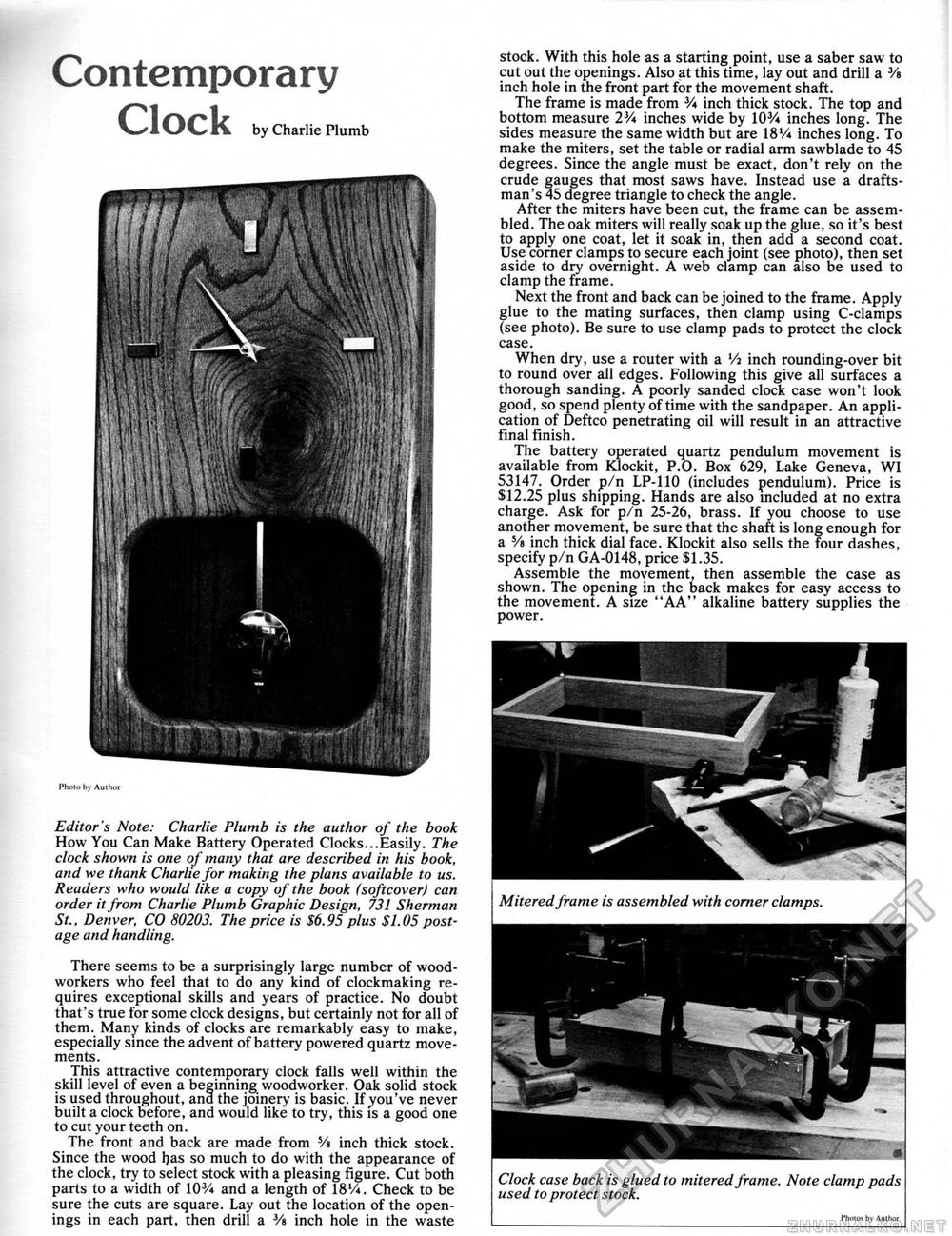

stock. With this hole as a starting point, use a saber saw to cut out the openings. Also at this time, lay out and drill a Vs inch hole in the front part for the movement shaft. The frame is made from V* inch thick stock. The top and bottom measure 2V* inches wide by 10V* inches long. The sides measure the same width but are 18'/« inches long. To make the miters, set the table or radial arm sawblade to 45 degrees. Since the angle must be exact, don't rely on the crude gauges that most saws have. Instead use a draftsman's 45 degree triangle to check the angle. After the miters have been cut, the frame can be assembled. The oak miters will really soak up the glue, so it's best to apply one coat, let it soak in, then add a second coat. Use corner clamps to secure each joint (see photo), then set aside to dry overnight. A web clamp can also be used to clamp the frame. Next the front and back can be joined to the frame. Apply glue to the mating surfaces, then clamp using C-cIamps (see photo). Be sure to use clamp pads to protect the clock case. When dry, use a router with a Vi inch rounding-over bit to round over all edges. Following this give all surfaces a thorough sanding. A poorly sanded clock case won't look good, so spend plenty of time with the sandpaper. An application of Deftco penetrating oil will result in an attractive final finish. The battery operated quartz pendulum movement is available from Klockit, P.O. Box 629, Lake Geneva, WI 53147. Order p/n LP-110 (includes pendulum). Price is $12.25 plus shipping. Hands are also included at no extra charge. Ask for p/n 25-26, brass. If you choose to use another movement, be sure that the shaft is long enough for a SA inch thick dial face. Klockit also sells the four dashes, specify p/n GA-0148, price $1.35. Assemble the movement, then assemble the case as shown. The opening in the back makes for easy access to the movement. A size "AA" alkaline battery supplies the power. ContemporaryClock by Charlie Plumb Photo by Author Editor 's Note: Charlie Plumb is the author of the book How You Can Make Battery Operated Clocks...Easily. The clock shown is one of many that are described in his book, and we thank Charlie for making the plans available to us. Readers who would like a copy of the book (softcover) can order it from Charlie Plumb Graphic Design, 731 Sherman St.. Denver, CO 80203. The price is $6.95 plus $1.05 postage and handling. There seems to be a surprisingly large number of woodworkers who feel that to do any kind of clockmaking requires exceptional skills and years of practice. No doubt that's true for some clock designs, but certainly not for all of them. Many kinds of clocks are remarkably easy to make, especially since the advent of battery powered quartz movements. This attractive contemporary clock falls well within the skill level of even a beginning woodworker. Oak solid stock is used throughout, ana the joinery is basic. If you've never built a clock before, and would like to try, this is a good one to cut your teeth on. The front and back are made from Vt inch thick stock. Since the wood has so much to do with the appearance of the clock, try to select stock with a pleasing figure. Cut both parts to a width of 10V* and a length of I8V4. Check to be sure the cuts are square. Lay out the location of the openings in each part, then drill a 3/e inch hole in the waste Mitered frame is assembled with corner clamps. Clock case back is glued to mitered frame. Note clamp pads used to protect stock. Photos by Author |