Woodworker's Journal 1983-7-2, страница 48

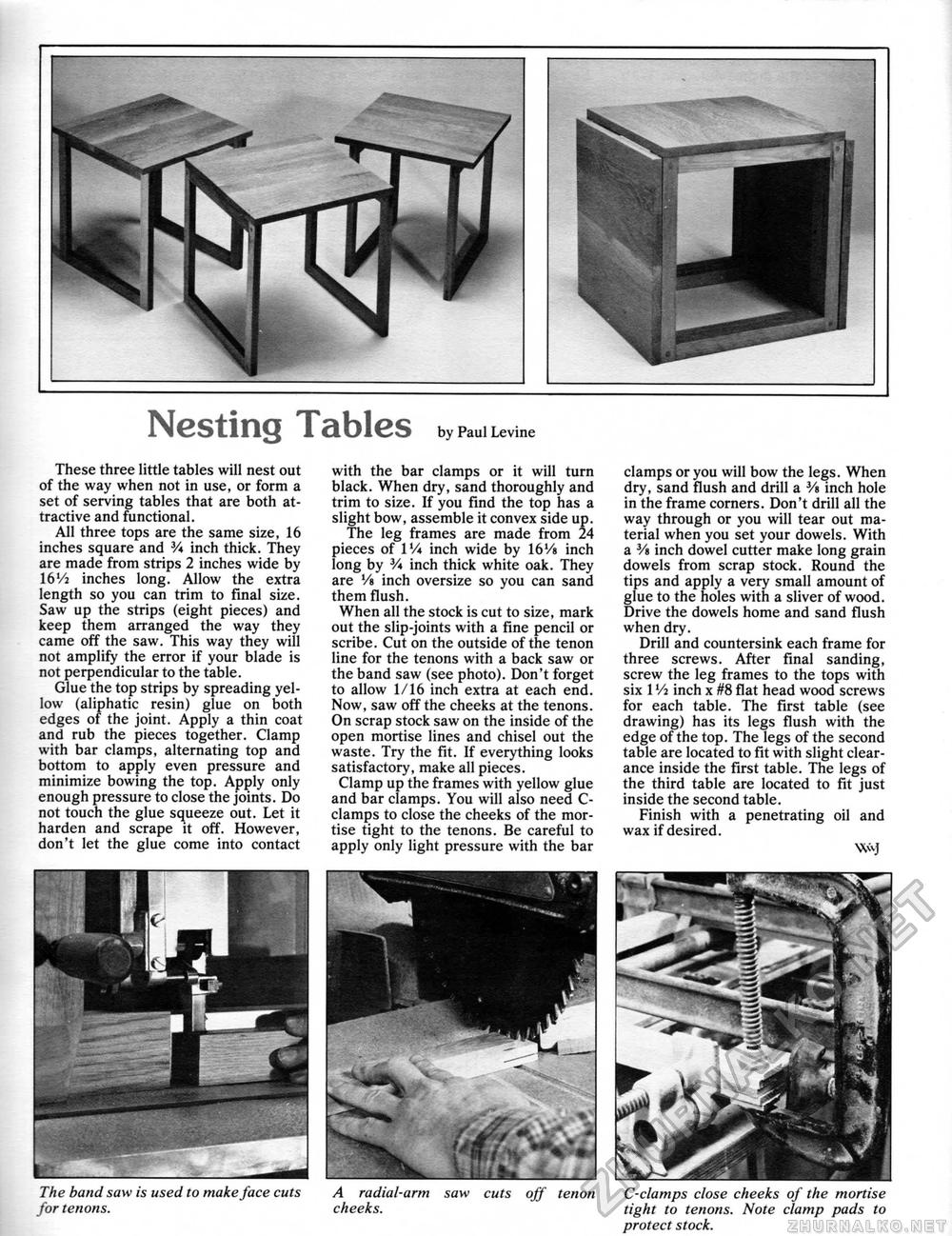

Nesting Tables by Paul Levine These three little tables will nest out of the way when not in use, or form a set of serving tables that are both attractive and functional. All three tops are the same size, 16 inches square and V* inch thick. They are made from strips 2 inches wide by 16 Vi inches long. Allow the extra length so you can trim to final size. Saw up the strips (eight pieces) and keep them arranged the way they came off the saw. This way they will not amplify the error if your blade is not perpendicular to the table. Glue the top strips by spreading yellow (aliphatic resin) glue on both edges of the joint. Apply a thin coat and rub the pieces together. Clamp with bar clamps, alternating top and bottom to apply even pressure and minimize bowing the top. Apply only enough pressure to close the joints. Do not touch the glue squeeze out. Let it harden and scrape it off. However, don't let the glue come into contact with the bar clamps or it will turn black. When dry, sand thoroughly and trim to size. If you find the top has a slight bow, assemble it convex side up. The leg frames are made from 24 pieces of 1'/« inch wide by 16V4 inch long by 3A inch thick white oak. They are Vs inch oversize so you can sand them flush. When all the stock is cut to size, mark out the slip-joints with a fine pencil or scribe. Cut on the outside of the tenon line for the tenons with a back saw or the band saw (see photo). Don't forget to allow 1/16 inch extra at each end. Now, saw off the cheeks at the tenons. On scrap stock saw on the inside of the open mortise lines and chisel out the waste. Try the fit. If everything looks satisfactory, make all pieces. Clamp up the frames with yellow glue and bar clamps. You will also need C-clamps to close the cheeks of the mortise tight to the tenons. Be careful to apply only light pressure with the bar clamps or you will bow the legs. When dry, sand flush and drill a Vs inch hole in the frame corners. Don't drill all the way through or you will tear out material when you set your dowels. With a Vs inch dowel cutter make long grain dowels from scrap stock. Round the tips and apply a very small amount of glue to the holes with a sliver of wood. Drive the dowels home and sand flush when dry. Drill and countersink each frame for three screws. After final sanding, screw the leg frames to the tops with six 1 Vi inch x #8 flat head wood screws for each table. The first table (see drawing) has its legs flush with the edge of the top. The legs of the second table are located to fit with slight clearance inside the first table. The legs of the third table are located to fit just inside the second table. Finish with a penetrating oil and wax if desired. WvJ The band saw is used to make face cuts A radial-arm saw cuts off tenon for tenons. cheeks. C-clamps close cheeks of the mortise tight to tenons. Note clamp pads to protect stock. |