Woodworker's Journal 1983-7-2, страница 47

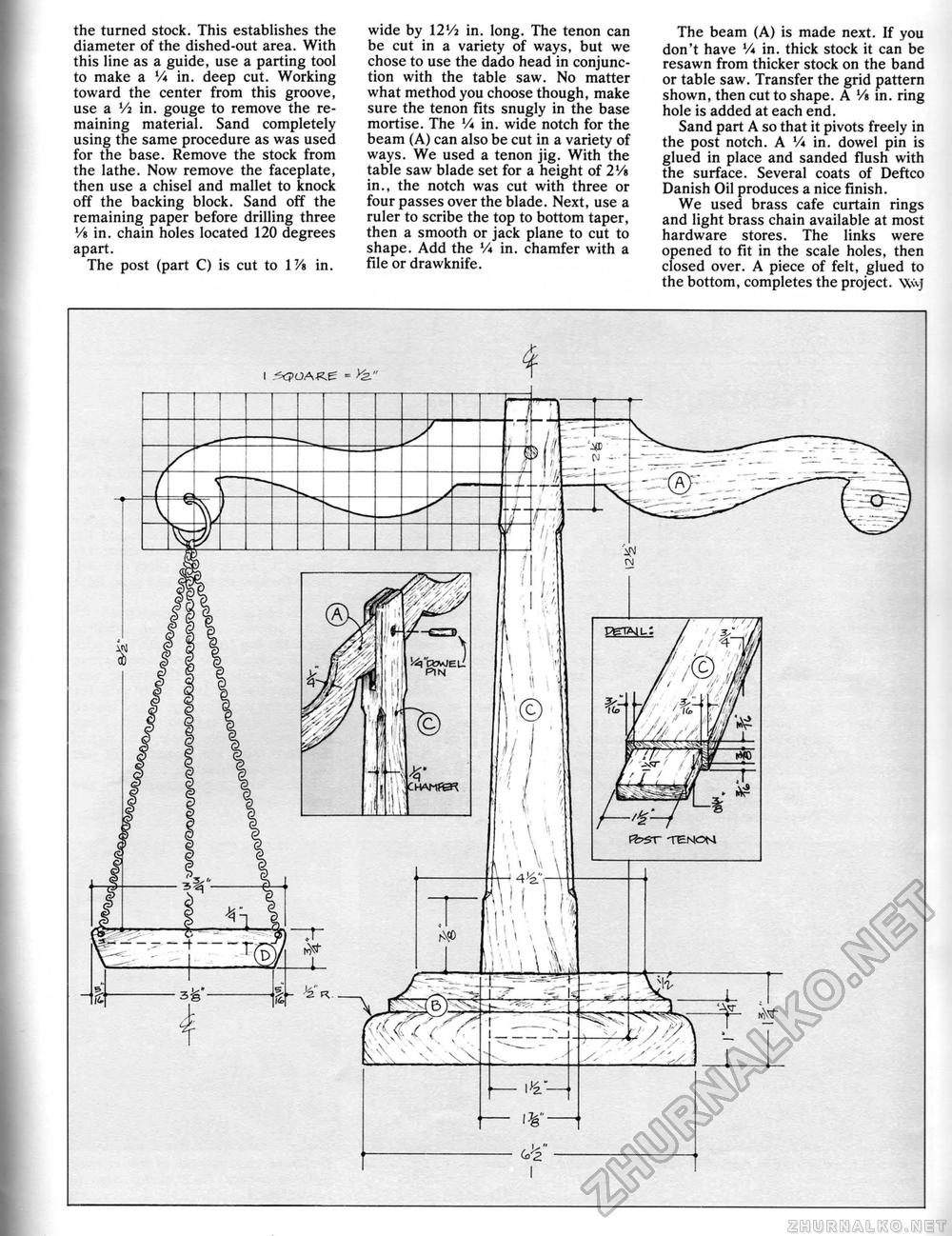

the turned stock. This establishes the diameter of the dished-out area. With this line as a guide, use a parting tool to make a V* in. deep cut. Working toward the center from this groove, use a Vi in. gouge to remove the remaining material. Sand completely using the same procedure as was used for the base. Remove the stock from the lathe. Now remove the faceplate, then use a chisel and mallet to knock off the backing block. Sand off the remaining paper before drilling three Vs in. chain holes located 120 degrees apart. The post (part C) is cut to 17s in. wide by 12'/2 in. long. The tenon can be cut in a variety of ways, but we chose to use the dado head in conjunction with the table saw. No matter what method you choose though, make sure the tenon fits snugly in the base mortise. The Vi in. wide notch for the beam (A) can also be cut in a variety of ways. We used a tenon jig. With the table saw blade set for a height of 2Vs in., the notch was cut with three or four passes over the blade. Next, use a ruler to scribe the top to bottom taper, then a smooth or jack plane to cut to shape. Add the Vi in. chamfer with a file or drawknife. The beam (A) is made next. If you don't have Vi in. thick stock it can be resawn from thicker stock on the band or table saw. Transfer the grid pattern shown, then cut to shape. A Vs in. ring hole is added at each end. Sand part A so that it pivots freely in the post notch. A V* in. dowel pin is glued in place and sanded flush with the surface. Several coats of Deftco Danish Oil produces a nice finish. We used brass cafe curtain rings and light brass chain available at most hardware stores. The links were opened to fit in the scale holes, then closed over. A piece of felt, glued to the bottom, completes the project. W\\j |