Woodworker's Journal 1983-7-2, страница 44

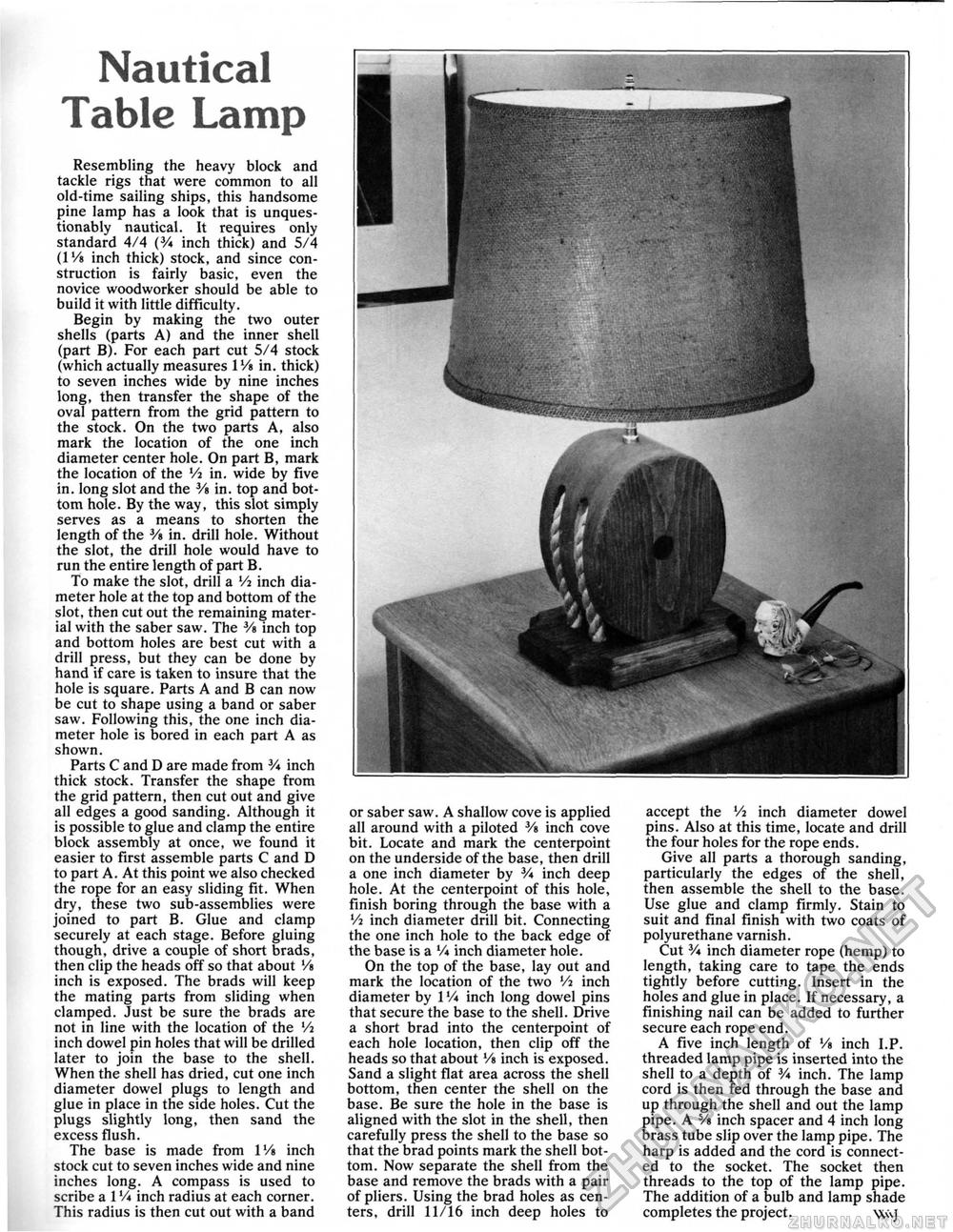

Nautical Table Lamp Resembling the heavy block and tackle rigs that were common to all old-time sailing ships, this handsome pine lamp has a look that is unquestionably nautical. It requires only standard 4/4 (V« inch thick) and 5/4 (l'/« inch thick) stock, and since construction is fairly basic, even the novice woodworker should be able to build it with little difficulty. Begin by making the two outer shells (parts A) and the inner shell (part B). For each part cut 5/4 stock (which actually measures 1 Vt in. thick) to seven inches wide by nine inches long, then transfer the shape of the oval pattern from the grid pattern to the stock. On the two parts A, also mark the location of the one inch diameter center hole. On part B, mark the location of the Vi in. wide by five in. long slot and the Vt in. top and bottom hole. By the way, this slot simply serves as a means to shorten the length of the Vt in. drill hole. Without the slot, the drill hole would have to run the entire length of part B. To make the slot, drill a Vt inch diameter hole at the top and bottom of the slot, then cut out the remaining material with the saber saw. The Vt inch top and bottom holes are best cut with a drill press, but they can be done by hand if care is taken to insure that the hole is square. Parts A and B can now be cut to shape using a band or saber saw. Following this, the one inch diameter hole is bored in each part A as shown. Parts C and D are made from V* inch thick stock. Transfer the shape from the grid pattern, then cut out and give all edges a good sanding. Although it is possible to glue and clamp the entire block assembly at once, we found it easier to first assemble parts C and D to part A. At this point we also checked the rope for an easy sliding fit. When dry, these two sub-assemblies were joined to part B. Glue and clamp securely at each stage. Before gluing though, drive a couple of short brads, then clip the heads off so that about Vt inch is exposed. The brads will keep the mating parts from sliding when clamped. Just be sure the brads are not in line with the location of the Vt inch dowel pin holes that will be drilled later to join the base to the shell. When the shell has dried, cut one inch diameter dowel plugs to length and glue in place in the side holes. Cut the plugs slightly long, then sand the excess flush. The base is made from 1 Vi inch stock cut to seven inches wide and nine inches long. A compass is used to scribe a 1V* inch radius at each corner. This radius is then cut out with a band or saber saw. A shallow cove is applied all around with a piloted Vt inch cove bit. Locate and mark the centerpoint on the underside of the base, then drill a one inch diameter by V* inch deep hole. At the centerpoint of this hole, finish boring through the base with a Vt inch diameter drill bit. Connecting the one inch hole to the back edge of the base is a V* inch diameter hole. On the top of the base, lay out and mark the location of the two Vt inch diameter by IV* inch long dowel pins that secure the base to the shell. Drive a short brad into the centerpoint of each hole location, then clip off the heads so that about Vt inch is exposed. Sand a slight flat area across the shell bottom, then center the shell on the base. Be sure the hole in the base is aligned with the slot in the shell, then carefully press the shell to the base so that the brad points mark the shell bottom. Now separate the shell from the base and remove the brads with a pair of pliers. Using the brad holes as centers, drill 11/16 inch deep holes to accept the Vi inch diameter dowel pins. Also at this time, locate and drill the four holes for the rope ends. Give all parts a thorough sanding, particularly the edges of the shell, then assemble the shell to the base. Use glue and clamp firmly. Stain to suit and final finish with two coats of polyurethane varnish. Cut Va inch diameter rope (hemp) to length, taking care to tape the ends tightly before cutting. Insert in the holes and glue in place. If necessary, a finishing nail can be added to further secure each rope end. A five inch length of Vt inch I.P. threaded lamp pipe is inserted into the shell to a depth of V* inch. The lamp cord is then fed through the base and up through the shell and out the lamp pipe. A Vt inch spacer and 4 inch long brass tube slip over the lamp pipe. The harp is added and the cord is connected to the socket. The socket then threads to the top of the lamp pipe. The addition of a bulb and lamp shade completes the project. \\\\j |