Woodworker's Journal 1983-7-2, страница 52

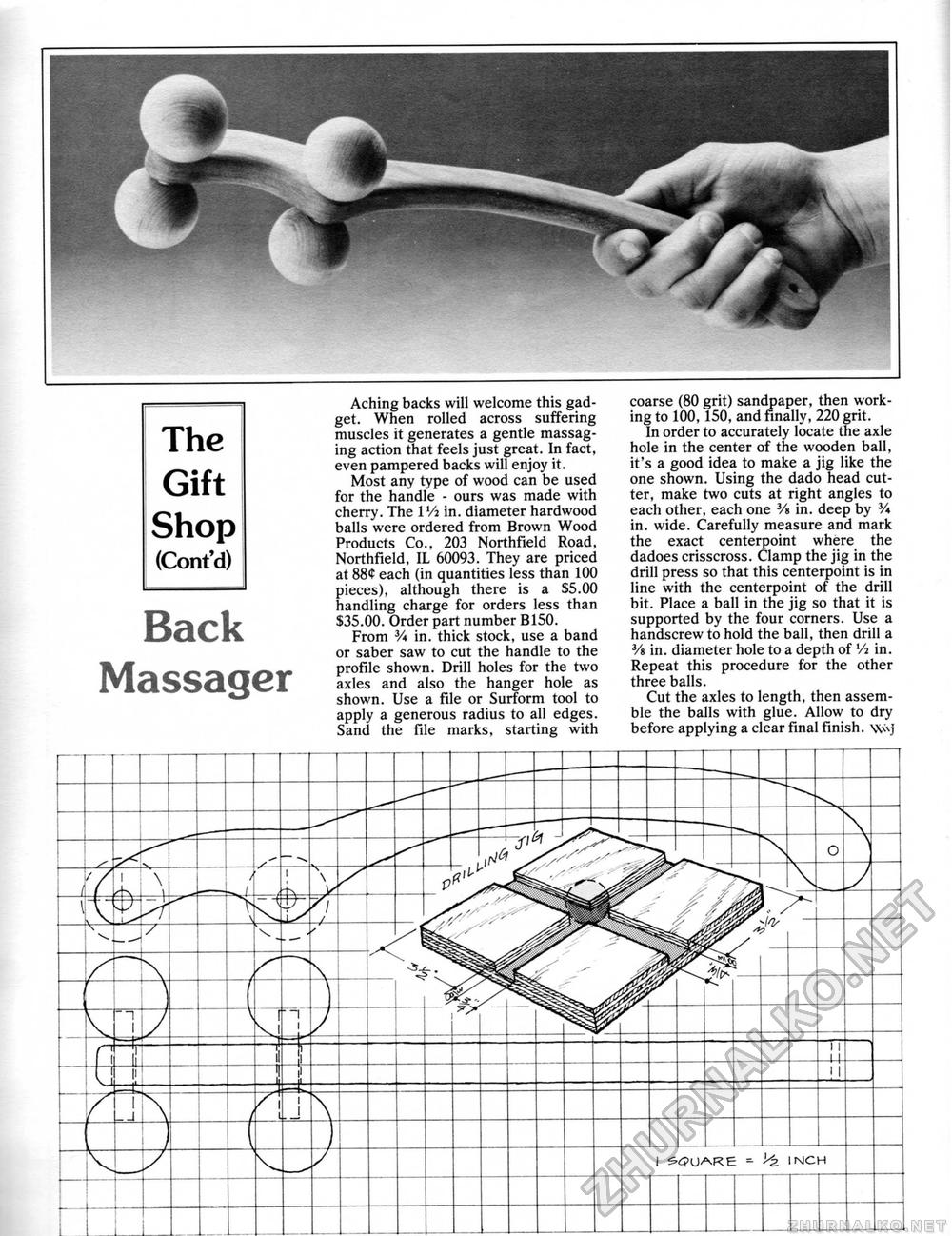

coarse (80 grit) sandpaper, then working to 100, 150, and finally, 220 grit. In order to accurately locate the axle hole in the center of the wooden ball, it's a good idea to make a jig like the one shown. Using the dado head cutter, make two cuts at right angles to each other, each one V» in. deep by V* in. wide. Carefully measure and mark the exact centerpoint where the dadoes crisscross. Clamp the jig in the drill press so that this centerpoint is in line with the centerpoint of the drill bit. Place a ball in the jig so that it is supported by the four corners. Use a handscrew to hold the ball, then drill a Vs in. diameter hole to a depth of Vi in. Repeat this procedure for the other three balls. Cut the axles to length, then assemble the balls with glue. Allow to dry before applying a clear final finish. \\<\j Back Massager Aching backs will welcome this gadget. When rolled across suffering muscles it generates a gentle massaging action that feels just great. In fact, even pampered backs will enjoy it. Most any type of wood can be used for the handle - ours was made with cherry. The l'/a in. diameter hardwood balls were ordered from Brown Wood Products Co., 203 Northfield Road, Northfield, IL 60093. They are priced at 88<t each (in quantities less than 100 pieces), although there is a $5.00 handling charge for orders less than $35.00. Order part number B150. From V* in. thick stock, use a band or saber saw to cut the handle to the profile shown. Drill holes for the two axles and also the hanger hole as shown. Use a file or Surform tool to apply a generous radius to all edges. Sand the file marks, starting with INCH |