Woodworker's Journal 1983-7-2, страница 55

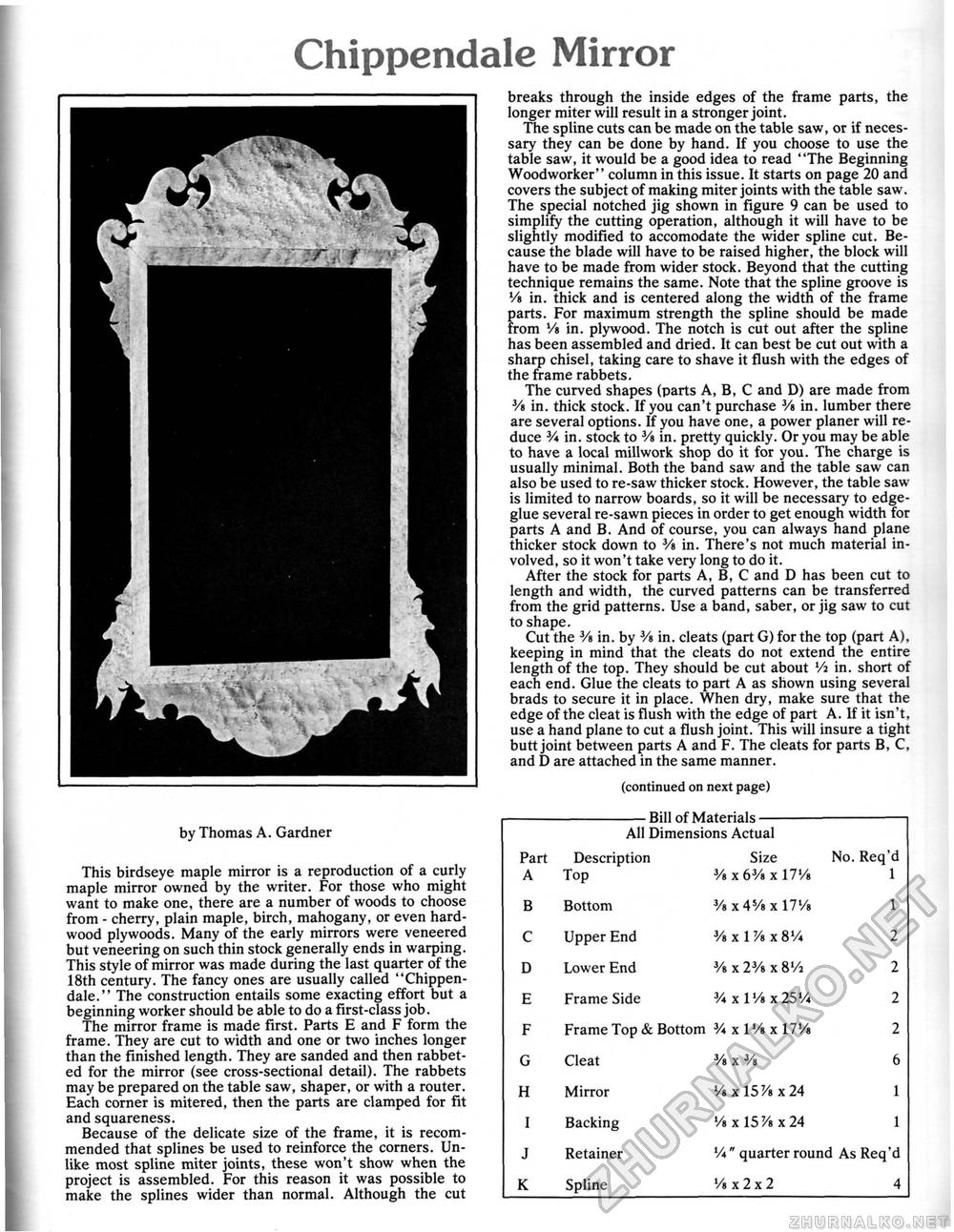

Chippendale Mirror by Thomas A. Gardner This birdseye maple mirror is a reproduction of a curly maple mirror owned by the writer. For those who might want to make one, there are a number of woods to choose from - cherry, plain maple, birch, mahogany, or even hardwood plywoods. Many of the early mirrors were veneered but veneering on such thin stock generally ends in warping. This style of mirror was made during the last quarter of the 18th century. The fancy ones are usually called "Chippendale." The construction entails some exacting effort but a beginning worker should be able to do a first-class job. The mirror frame is made first. Parts E and F form the frame. They are cut to width and one or two inches longer than the finished length. They are sanded and then rabbeted for the mirror (see cross-sectional detail). The rabbets may be prepared on the table saw, shaper, or with a router. Each corner is mitered, then the parts are clamped for fit and squareness. Because of the delicate size of the frame, it is recommended that splines be used to reinforce the corners. Unlike most spline miter joints, these won't show when the project is assembled. For this reason it was possible to make the splines wider than normal. Although the cut breaks through the inside edges of the frame parts, the longer miter will result in a stronger joint. The spline cuts can be made on the table saw, or if necessary they can be done by hand. If you choose to use the table saw, it would be a good idea to read "The Beginning Woodworker" column in this issue. It starts on page 20 and covers the subject of making miter joints with the table saw. The special notched jig shown in figure 9 can be used to simplify the cutting operation, although it will have to be slightly modified to accomodate the wider spline cut. Because the blade will have to be raised higher, the block will have to be made from wider stock. Beyond that the cutting technique remains the same. Note that the spline groove is Vs in. thick and is centered along the width of the frame parts. For maximum strength the spline should be made from Vs in. plywood. The notch is cut out after the spline has been assembled and dried. It can best be cut out with a sharp chisel, taking care to shave it flush with the edges of the frame rabbets. The curved shapes (parts A, B, C and D) are made from Vs in. thick stock. If you can't purchase Vs in. lumber there are several options. If you have one, a power planer will reduce V* in. stock to Vs in. pretty quickly. Or you may be able to have a local millwork shop do it for you. The charge is usually minimal. Both the band saw and the table saw can also be used to re-saw thicker stock. However, the table saw is limited to narrow boards, so it will be necessary to edge-glue several re-sawn pieces in order to get enough width for parts A and B. And of course, you can always hand plane thicker stock down to Vs in. There's not much material involved, so it won't take very long to do it. After the stock for parts A, B, C and D has been cut to length and width, the curved patterns can be transferred from the grid patterns. Use a band, saber, or jig saw to cut to shape. Cut the Vs in. by Vs in. cleats (part G) for the top (part A), keeping in mind that the cleats do not extend the entire length of the top. They should be cut about Vi in. short of each end. Glue the cleats to part A as shown using several brads to secure it in place. When dry, make sure that the edge of the cleat is flush with the edge of part A. If it isn't, use a hand plane to cut a flush joint. This will insure a tight butt joint between parts A and F. The cleats for parts B, C, and D are attached in the same manner. (continued on next page) — Bill of Materials — All Dimensions Actual

|