Woodworker's Journal 1983-7-3, страница 42

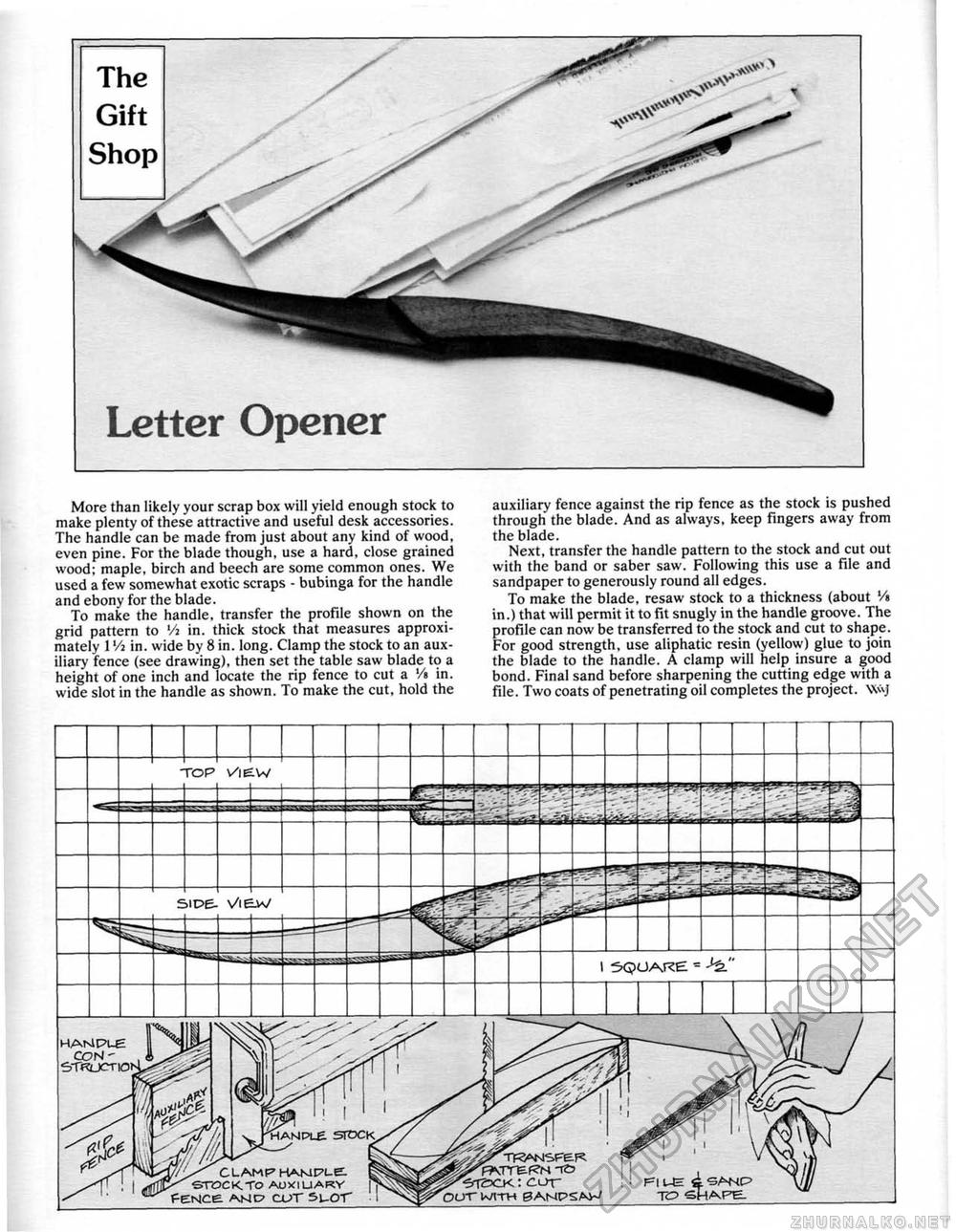

More than likely your scrap box will yield enough stock to make plenty of these attractive and useful desk accessories. The handle can be made from just about any kind of wood, even pine. For the blade though, use a hard, close grained wood; maple, birch and beech are some common ones. We used a few somewhat exotic scraps - bubinga for the handle and ebony for the blade. To make the handle, transfer the profile shown on the grid pattern to Vi in. thick stock that measures approximately 1 '/i in. wide by 8 in. long. Clamp the stock to an auxiliary fence {see drawing), then set the table saw blade to a height of one inch and locate the rip fence to cut a Vt in. wide slot in the handle as shown. To make the cut, hold the auxiliary fence against the rip fence as the stock is pushed through the blade. And as always, keep fingers away from the blade. Next, transfer the handle pattern to the stock and cut out with the band or saber saw. Following this use a file and sandpaper to generously round all edges. To make the blade, resaw stock to a thickness (about Vt in.) that will permit it to fit snugly in the handle groove. The profile can now be transferred to the stock and cut to shape. For good strength, use aliphatic resin (yellow) glue to join the blade to the handle. A clamp will help insure a good bond. Final sand before sharpening the cutting edge with a file. Two coats of penetrating oil completes the project. W\J |