Woodworker's Journal 1983-7-3, страница 43

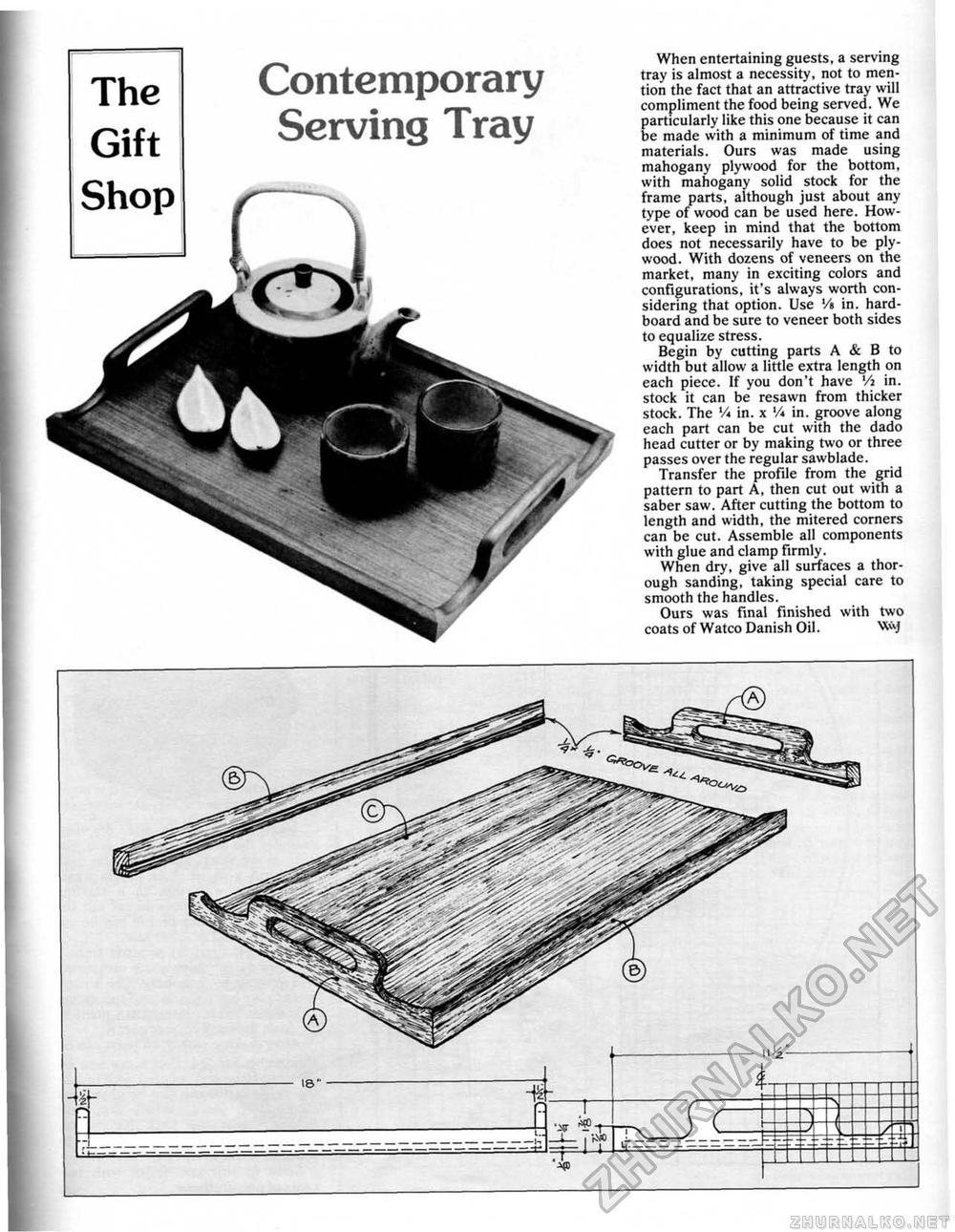

When entertaining guests, a serving tray is almost a necessity, not to mention the fact that an attractive tray will compliment the food being served. We particularly like this one because it can be made with a minimum of time and materials. Ours was made using mahogany plywood for the bottom, with mahogany solid stock for the frame parts, although just about any type of wood can be used here. However, keep in mind that the bottom does not necessarily have to be plywood. With dozens of veneers on the market, many in exciting colors and configurations, it's always worth considering that option. Use '/» in. hard-board and be sure to veneer both sides to equalize stress. Begin by cutting parts A & B to width but allow a little extra length on each piece. If you don't have 'A in. stock it can be resawn from thicker stock. The V* in. x lA in. groove along each part can be cut with the dado head cutter or by making two or three passes over the regular sawblade. Transfer the profile from the grid pattern to pan A, then cut out with a saber saw. After cutting the bottom to length and width, the mitered corners can be cut. Assemble all components with giue and clamp firmly. When dry, give all surfaces a thorough sanding, taking special care to smooth the handles. Ours was final finished with two coats of Watco Danish Oil. W*i Contemporary Serving Tray |