Woodworker's Journal 1983-7-5, страница 16

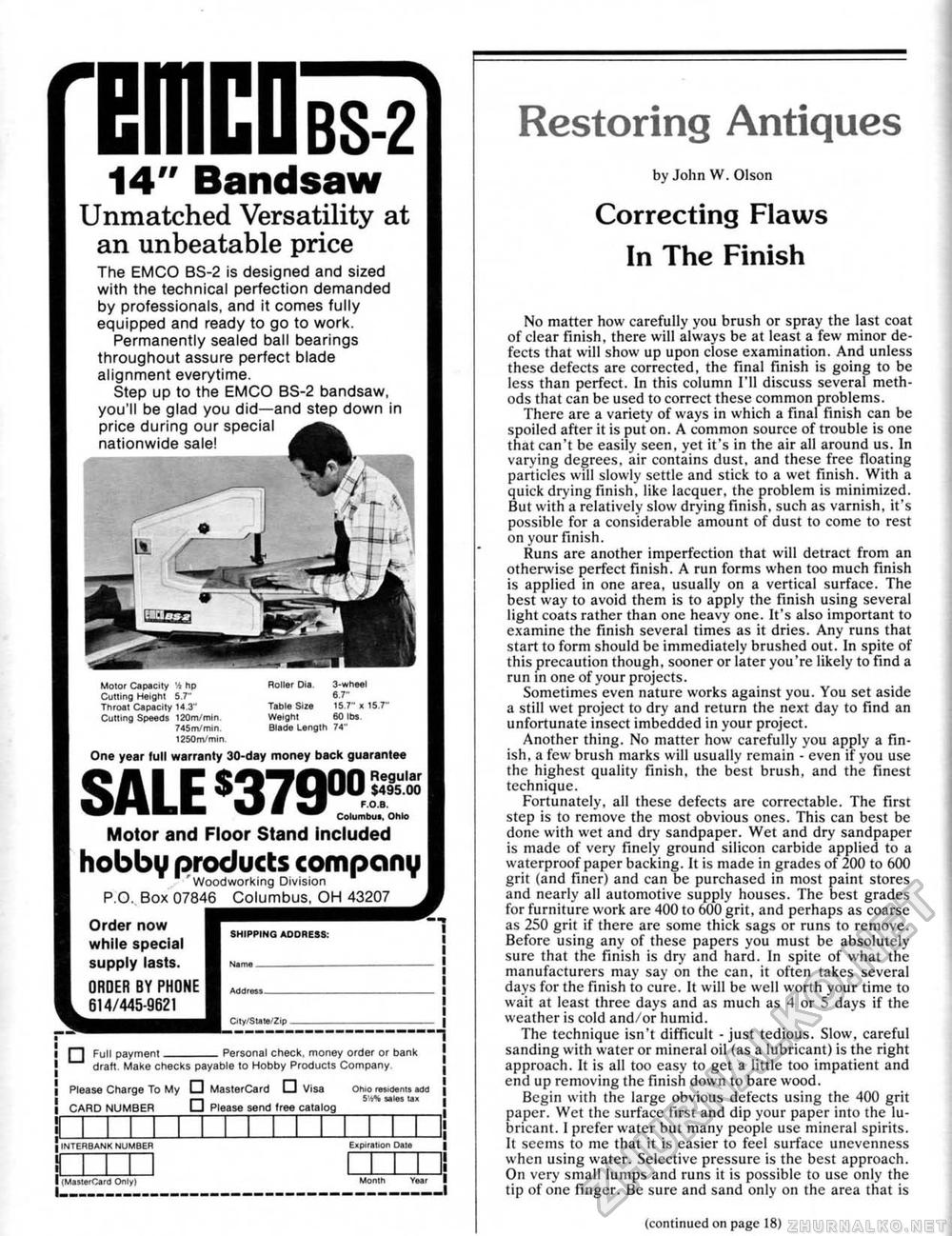

BS-214" Bandsaw Unmatched Versatility at an unbeatable price The EMCO BS-2 is designed and sized with the technical perfection demanded by professionals, and it comes fully equipped and ready to go to work. Permanently sealed bail bearings throughout assure perfect blade alignment everytime. Step up to the EMCO BS-2 bandsaw, you'll be glad you did—and step down in price during our special nationwide sale! Motor Capacity tip Cutting Heigh i 5.7" Throat Capacity 14.3" Cutting Speeds IJCm/mln 745m/min. Roller Dra 3-wheel 8.7" Table Size 15 7" * 15 7" weigtit 60 lbs. Blade Length 7A" SALE $379°1 1250m/min. One year lull warranty 30-day money back guarantee Regular $495.00 F.O.B. Columbus, Ohio Motor and Floor Stand included hobby products company 'Woodworking Division P.O. Box 07846 Columbus, OH 43207 Order now while special supply lasts. ORDER BY PHONE 614/445-9621 ! ] Full payment. SHIPPING ADDRESS: Cily/Slatoi'Zip . . Personal check, money order or bank drafl. Make checks payable lo Hobby Products Company Please Charge To My Q MasterCard ED Visa Oh.o roidenii sua CARD NUMBER_O Please send tree catalog 5 .S sales tax Expiration Dale Month Year Restoring Antiques by John W. Olson Correcting Flaws In The Finish No matter how carefully you brush or spray the last coat of clear finish, there will always be at least a few minor defects that will show up upon close examination. And unless these defects are corrected, the final finish is going to be less than perfect. In this column I'll discuss several methods that can be used to correct these common problems. There are a variety of ways in which a final finish can be spoiled after it is put on. A common source of trouble is one that can't be easily seen, yet it's in the air all around us. In varying degrees, air contains dust, and these free floating particles will slowly settle and stick to a wet finish. With a quick drying finish, like lacquer, the problem is minimized. But with a relatively slow drying finish, such as varnish, it's possible for a considerable amount of dust to come to rest on your finish. Runs are another imperfection that will detract from an otherwise perfect finish, A run forms when too much finish is applied in one area, usually on a vertical surface. The best way to avoid them is to apply the finish using several light coats rather than one heavy one. It's also important to examine the finish several times as it dries. Any runs that start to form should be immediately brushed out. In spite of this precaution though, sooner or later you're likely to find a run in one of your projects. Sometimes even nature works against you. You set aside a still wet project to dry and return the next day to find an unfortunate insect imbedded in your project. Another thing. No matter how carefully you apply a finish, a few brush marks will usually remain - even if you use the highest quality finish, the best brush, and the finest technique. Fortunately, all these defects are correctable. The first step is to remove the most obvious ones. This can best be done with wet and dry sandpaper. Wet and dry sandpaper is made of very finely ground silicon carbide applied to a waterproof paper backing. It is made in grades of 200 to 600 grit (and finer) and can be purchased in most paint stores and nearly all automotive supply houses. The best grades for furniture work are 400 to 600 grit, and perhaps as coarse as 250 grit if there are some thick sags or runs to remove. Before using any of these papers you must be absolutely sure that the finish is dry and hard. In spite of what the manufacturers may say on the can, it often takes several days for the finish to cure. It will be well worth your time to wait at least three days and as much as 4 or 5 days if the weather is cold and/or humid. The technique isn't difficult - just tedious. Slow, careful sanding with water or mineral oil (as a lubricant) is the right approach. It is all too easy to get a little too impatient and end up removing the finish down to bare wood. Begin with the large obvious defects using the 400 grit paper. Wet the surface first and dip your paper into the lubricant. I prefer water but many people use mineral spirits. It seems to me that it is easier to feel surface unevenncss w:hen using water. Selective pressure is the best approach. On very small lumps and runs it is possible to use only the tip of one finger. Be sure and sand only on the area that is (continued on page 18) State. Zip . |