Woodworker's Journal 1983-7-5, страница 22

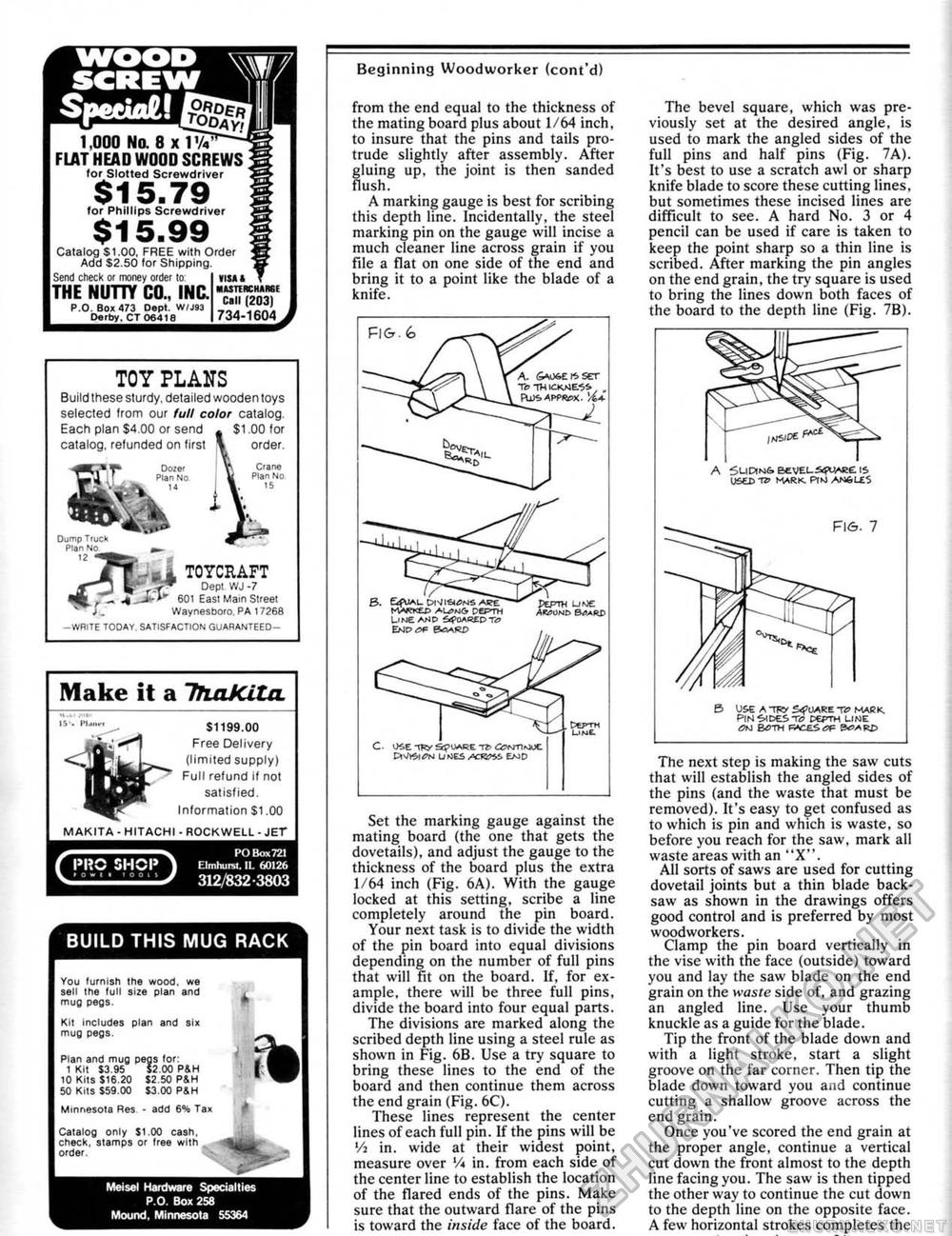

jSSfy*' 1,000 No. 8 x 1W FLAT HEAD WOOD SCREWS for Slotted Screwdriver $15.79 tor Phillips Screwdriver $15.99 Catalog 51.00, FREE with Order Add $2.50 lor Shipping. Send check or money order to: THE NUTIY CO., INC. P.O. Box473 Dept. w/jsa Derby, CT 06418 »ISA» KUHKMR6E Call (203) 734-1604 A TOY PLANS Build these sturdy, detailed wooden toys selected from our full color catalog Each plan $4.00 or send 8 $1,00 for catalog, refunded on first \ order ifci. TOYCRAFT (j - Depl WJ -7 _ f ^ ^ . Ji- 601 Easl Mam Street ) , Waynesboro. PA 17268 — WRITE TODAY SATISFACTION GUARANTEED — Make it a 7haJCita. $1199.00 Free Delivery (limited supply) Full refund if not satisfied. Information $1.00 MAKITA - HITACHI - ROCKWELL ■ JET PRC SHOP PO Bon 721 Elmhurst, It. 60126 312/S32-3803 BUILD THIS MUG RACK You furnish the wood, wo sell Ihe lull size plan and mug pegs. Kit includes plan and Six mug pegs. Plan and mug pegs for 1 Kit 13 95 S2 00 P&H 10 Kils S16.20 S2 50 P&H 50 Kils S59.00 S3.00 P&H Minnesota Res - add 6% Tax Catalog only $1.00 cash, ctieck, stamps or tree with order Meisel Hardware Specialties P.O. Box 258 Mound, Minnesota 55364 Beginning Woodworker (cont'd) from the end equal to the thickness of the mating board plus about 1/64 inch, to insure that the pins and tails protrude slightly after assembly. After gluing up, the joint is then sanded flush. A marking gauge is best for scribing this depth line. Incidentally, the steel marking pin on the gauge will incise a much cleaner line across grain if you file a flat on one side of the end and bring it to a point like the blade of a knife. A. Te lUlCKHEt* , Set the marking gauge against the mating board (the one that gets the dovetails), and adjust the gauge to the thickness of the board plus the extra 1/64 inch (Fig. 6A). With the gauge locked at this setting, scribe a line completely around the pin board. Your next task is to divide the width of the pin board into equal divisions depending on the number of full pins that will fit on the board. If, for example, there will be three full pins, divide the board into four equal parts. The divisions are marked along the scribed depth line using a steel rule as shown in Fig. 6B. Use a try square to bring these lines to the end of the board and then continue them across the end grain (Fig. 6C). These lines represent the center lines of each full pin. If the pins will be Vi in. wide at their widest point, measure over V* in. from each side of the center iine to establish the location of the flared ends of the pins. Make sure that the outward flare of the pins is toward the inside face of the board. The bevel square, which was previously set at the desired angle, is used to mark the angled sides of the full pins and half pins (Fig. 7A). It's best to use a scratch awl or sharp knife blade to score these cutting lines, but sometimes these incised lines are difficult to see. A hard No. 3 or 4 pencil can be used if care is taken lo keep the point sharp so a thin line is scribed. After marking the pin angles on the end grain, the try square is used to bring the lines down both faces of the board to the depth line (Fig. 7B). USED TP MARK HU AN&LES F\&. 7 3 U&E A TRr SQUARE TiS MACK. PlfJ CCS -fH £3£pTH UME on Both The next step is making the saw cuts that will establish the angled sides of the pins (and the waste that must be removed). It's easy to get confused as to which is pin and which is waste, so before you reach for the saw, mark all waste areas with an "X". All sorts of saws are used for cutting dovetail joints but a thin blade back-saw as shown in the drawings offers good control and is preferred by most woodworkers. Clamp the pin board vertically in the vise with the face (outside) toward you and lay the saw blade on the end grain on the waste side of, and grazing an angled line. Use your thumb knuckle as a guide for the blade. Tip the front of the blade down and with a light stroke, start a slight groove on the far corner. Then tip the blade down toward you atid continue cutting a shallow groove across the end grain. Once you've scored the end grain at the proper angle, continue a vertical cut down the front almost to the depth line facing you. The saw is then tipped the other way to continue the cut down to the depth line on the opposite face. A few horizontal strokes completes the C- IKE "BV Tt> CJMT1MUC PWr-=>li?N UUES ACR^i Pep-™ UNI Lli^E BAARD |