Woodworker's Journal 1983-7-5, страница 20

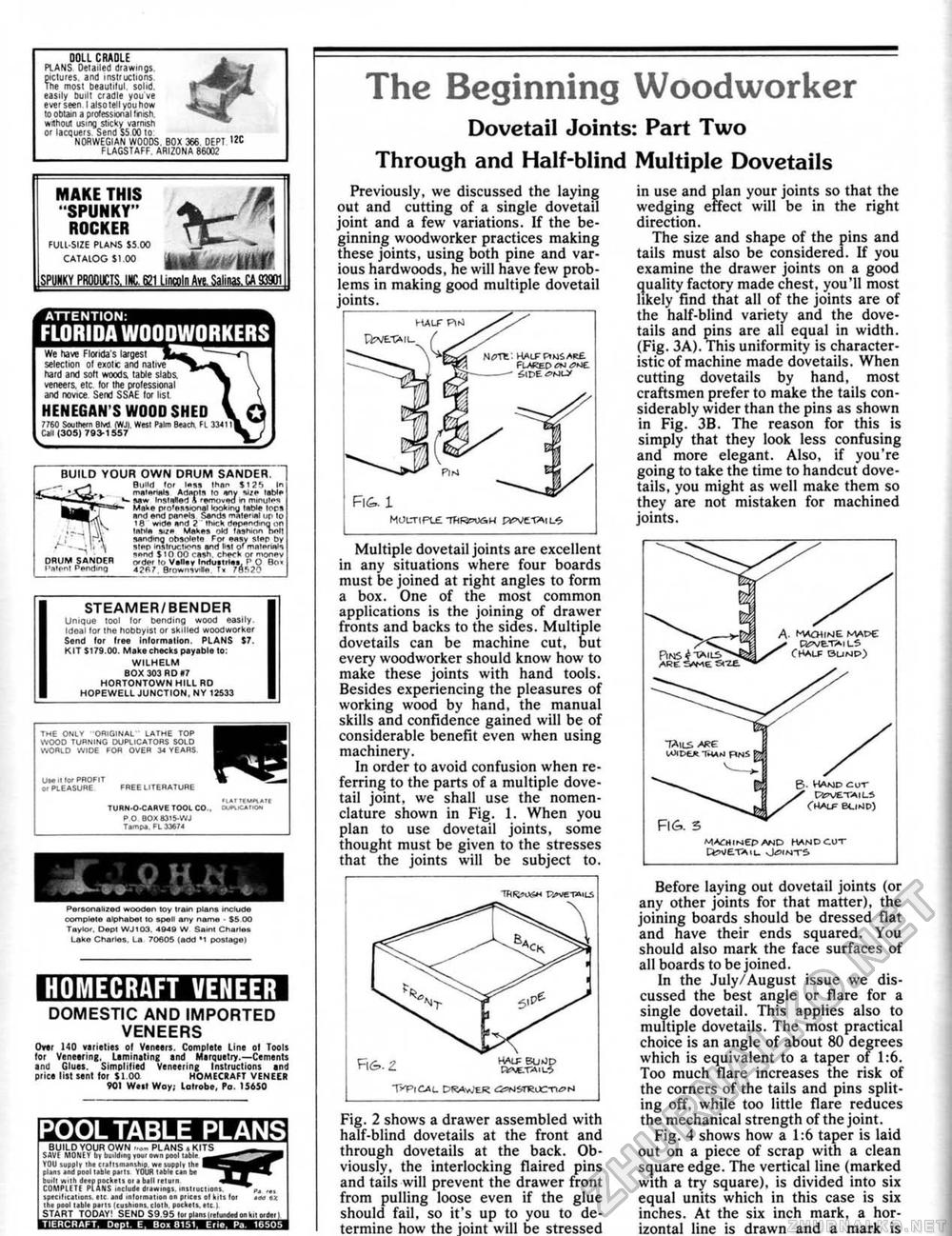

OOLL CRADLE PLANS Delailed Drawings Die lures, and instructions The most beautilul. solid, easily t)uilI cradle you've ever seen. I alsoteil youho* to ostain a picrfessional rush, without using slicky varnish or lacquers Send $5 00 10 NORWEGIAN WOODS BOX 366 DEPT I" FLAGSTAFF ARIZONA 8500? V fM MAKE THIS "SPUNKY" ROCKER FUtt-SIZE PLANS £5.00 catalog si oo ^Mfc jf ftiliff SPUHKV PRODUCTS. INC. S21 Lincoln Ave. Salinas. M 93901 BUILD YOUR OWN DRUM SANDER. Build lor l»ma than Si 25 in mninrtflls Atlnpla to any size labia - saw installed K romovM in minute* Make professional looking taWe lor® and end panels Sands material up lo u^ 19 wide and ? thick depending t>n u iftNa su" Makes old fashion V>lt aandng obsolete For easy sler by 5tap mstructmns and ReJ of mnterWn _ ____ *nnd $ 10 00 cash, check of money DRUM SANDER fydar j0 Vellsy fnriuitriaij P O Bo* Pftle-M Peod<nq +2*7 Brownsville T* 7 STEAMER/BENDER Unique tool for tending wood easily Ideal tor the hob&yist or skilled woodworker Send for free information. PLANS S7. KIT S179.00. Make checks payable to: WILHELM BOX 303 BD #7 HOftTONTOWN HILL RD HOPEWELL JUNCTION, NY 12533 THE ONLY ORIGINAL LATHE TOP WOOD TURNING DUPLICATORS SOLD WORLD WIDE FOR OVER 34 YEARS Uftfr "I lot PROFIT Of PLEASURE FREE LITERATURE TURN-O-CARVE TOOL CO., P O BOX &3l 5-WJ Timpa. FL 13674 Personalized wooden toy train plans include complete alphabet to spell any name - SS OO Toy tor. Depl WJ103. 4049 W Saint Charles Lake Charles. La 70605 (add M postage) HOMECRAFT VENEER DOMESTIC AND IMPORTED VENEERS Ova: 140 varieties ot Veneers. Complete Line ol Tools tot Veneering, Uminating end Marquetry.—Ceminis and Glues, Simplified Veneering Instructions and price list sent for $1 00 HOMECRAFT VENEER 901 WmI Woy; tolrobe, Pa. 15650 POOL TABLE PLANS BUILD YOUB OWN PLANS * KITS SAVE MONEY by building v»ur oen pool tabln YOU supply crallim.ini.liip. we supply ihc pi am and pool tafaU; paris YOUR table can be built with deep packet* 01 a ball lelum COMPUTE PIANS tncludir drawings instruction specifications, etc and information on prices ol hits loi the pool table parts Icushions. cloth, pockets, etc.] START TOO AY? SEND S9.95 lor plaits (refunded TIERCRAFT. Dept. E. Box 8151, Erie. Pa. 16505 The Beginning Woodworker Dovetail Joints: Part Two Through and Half-blind Multiple Dovetails Previously, we discussed the laying out and cutting of a single dovetail joint and a few variations. If the beginning woodworker practices making these joints, using both pine and various hardwoods, he will have few problems in making good multiple dovetail joints. HALF" PIPI CWEXAIU NiTTV FutKEO ew f MOCTIPLE Tftranuan Rs^t-TAi L-5 Multiple dovetail joints are excellent in any situations where four boards must be joined at right angles to form a box. One of the most common applications is the joining of drawer fronts and backs to the sides. Multiple dovetails can be machine cut, but every woodworker should know how to make these joints with hand tools. Besides experiencing the pleasures of working wood by hand, the manual skills and confidence gained will be of considerable benefit even when using machinery. In order to avoid confusion when referring to the parts of a multiple dovetail joint, we shall use the nomenclature shown in Fig. 1. When you plan to use dovetail joints, some thought must be given to the stresses that the joints will be subject to. TTifSsijsM n«ie-p»iLS Topical. DRAPER a^vmocn^n Fig. 2 shows a drawer assembled with half-blind dovetails at the front and through dovetails at the back. Obviously, the interlocking flaired pins and tails will prevent the drawer front from pulling loose even if the glue should fail, so it's up to you to determine how the joint will be stressed in use and plan your joints so that the wedging effect will be in the right direction. The size and shape of the pins and tails must also be considered. If you examine the drawer joints on a good Cjuality factory made chest, you'll most likely find that all of the joints are of the half-blind variety and the dovetails and pins are ail equal in width. (Fig. 3A). This uniformity is characteristic of machine made dovetails. When cutting dovetails by hand, most craftsmen prefer to make the tails considerably wider than the pins as shown in Fig. 3B. The reason for this is simply that they look less confusing and more elegant. Also, if you're going to take the time to handcut dovetails, you might as well make them so they are not mistaken for machined joints. tails ARE SilE A- 1-VtOtlNE MAt>£ ' RJ'VfeTAiL'S (HALF BUMP) . Hand CUT P23VETA IL.S fMAjjr BOiJM Ft 6. 3 MA£HIN£P AMD httNDCUT CfnlETAlL. 0(51 NTS Before laying out dovetail joints (or any other joints for that matter), the joining boards should be dressed flat and have their ends squared. You should also mark the face surfaces of all boards to be joined. In the July/August issue we discussed the best angle or flare for a single dovetail. This applies also to multiple dovetails. The most practical choice is an angle of about 80 degrees which is equivalent to a taper of 1:6. Too much flare increases the risk of the corners of the tails and pins spitting off, while too little flare reduces the mechanical strength of the joint. Fig. 4 shows how a 1:6 taper is laid out on a piece of scrap with a clean square edge. The vertical line (marked with a try square), is divided into six equal units which in this case is six inches. At the six inch mark, a horizontal line is drawn and a mark is Ws haw Florida's selection ot t hard and soli veneers, etc tot and novice Send HENEGAN S WOODSHED 7760 Soultiern BM IWJI W«l Film Beldi Fl Ml 1305) 793-1557 |