Woodworker's Journal 1983-7-5, страница 39

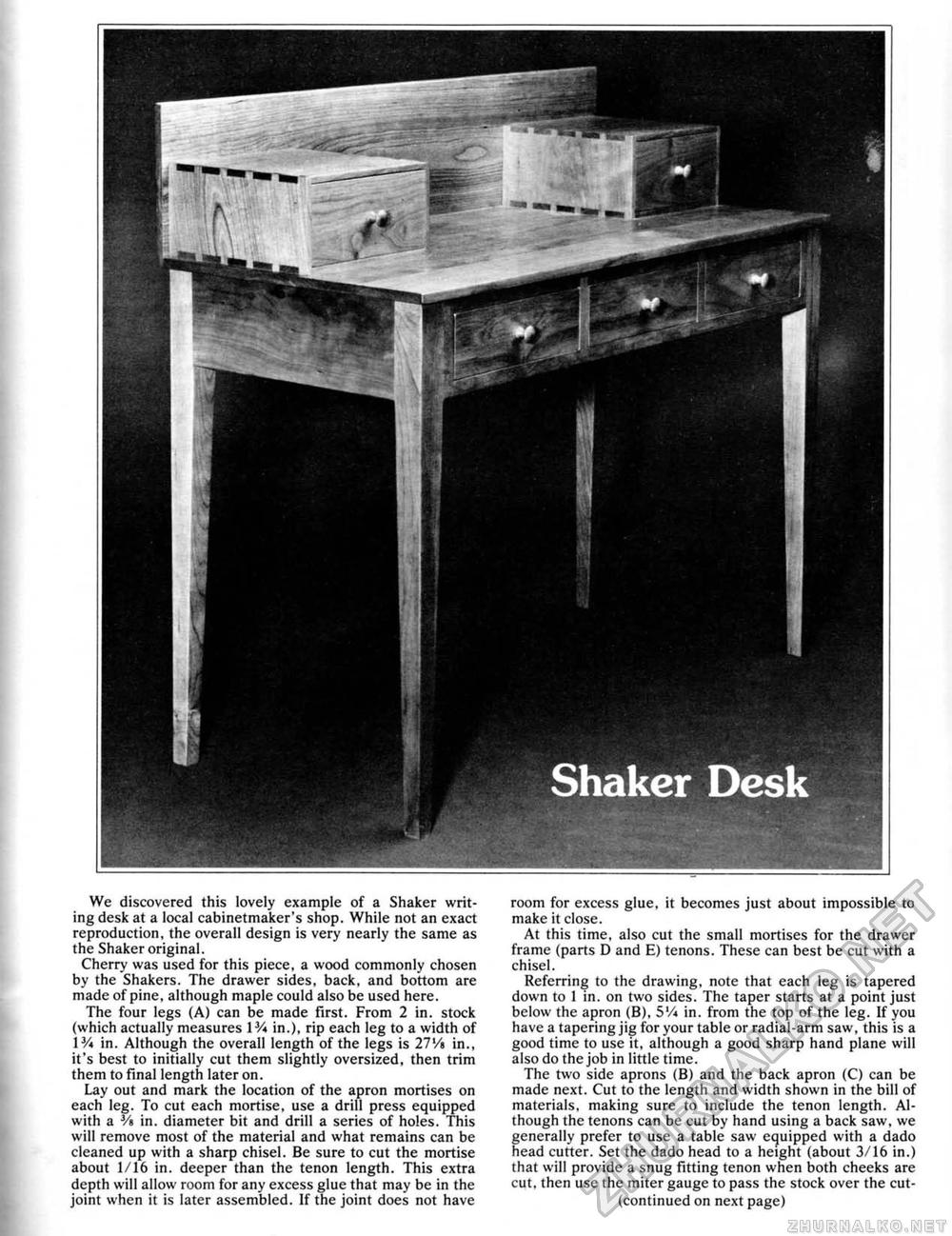

We discovered this lovely example of a Shaker writing desk at a local cabinetmaker's shop. While not an exact reproduction, the overall design is very nearly the same as the Shaker original. Cherry was used for this piece, a wood commonly chosen by the Shakers. The drawer sides, back, and bottom are made of pine, although maple could also be used here. The four legs (A) can be made first. From 2 in. stock (which actually measures IV* in.), rip each leg to a width of 1V* in. Although the overall length of the legs is 27'/« in., it's best to initially cut them slightly oversized, then trim them to final length later on. Lay out and mark the location of the apron mortises on each leg. To cut each mortise, use a drill press equipped with a Vs in. diameter bit and drill a series of holes. This will remove most of the material and what remains can be cleaned up with a sharp chisel. Be sure to cut the mortise about 1/16 in. deeper than the tenon length. This extra depth will allow room for any excess glue that may be in the joint when it is later assembled. If the joint does not have room for excess glue, it becomes just about impossible to make it close. At this time, also cut the small mortises for the drawer frame (parts D and E) tenons. These can best be cut with a chisel. Referring to the drawing, note that each leg is tapered down to 1 in. on two sides. The taper starts at a point just below the apron (B), 5% in. from the top of the leg. If you have a tapering jig for your table or radial-arm saw, this is a good time to use it, although a good sharp hand plane will also do the job in little time. The two side aprons (B) and the back apron (C) can be made next. Cut to the length and width shown in the bill of materials, making sure to include the tenon length. Although the tenons can be cut by hand using a back saw, we generally prefer to use a table saw equipped with a dado head cutter. Set the dado head to a height (about 3/16 in.) that will provide a snug fitting tenon when both cheeks are cut, then use the miter gauge to pass the stock over the cut-(continued on next page) |