Woodworker's Journal 1984-8-1, страница 20

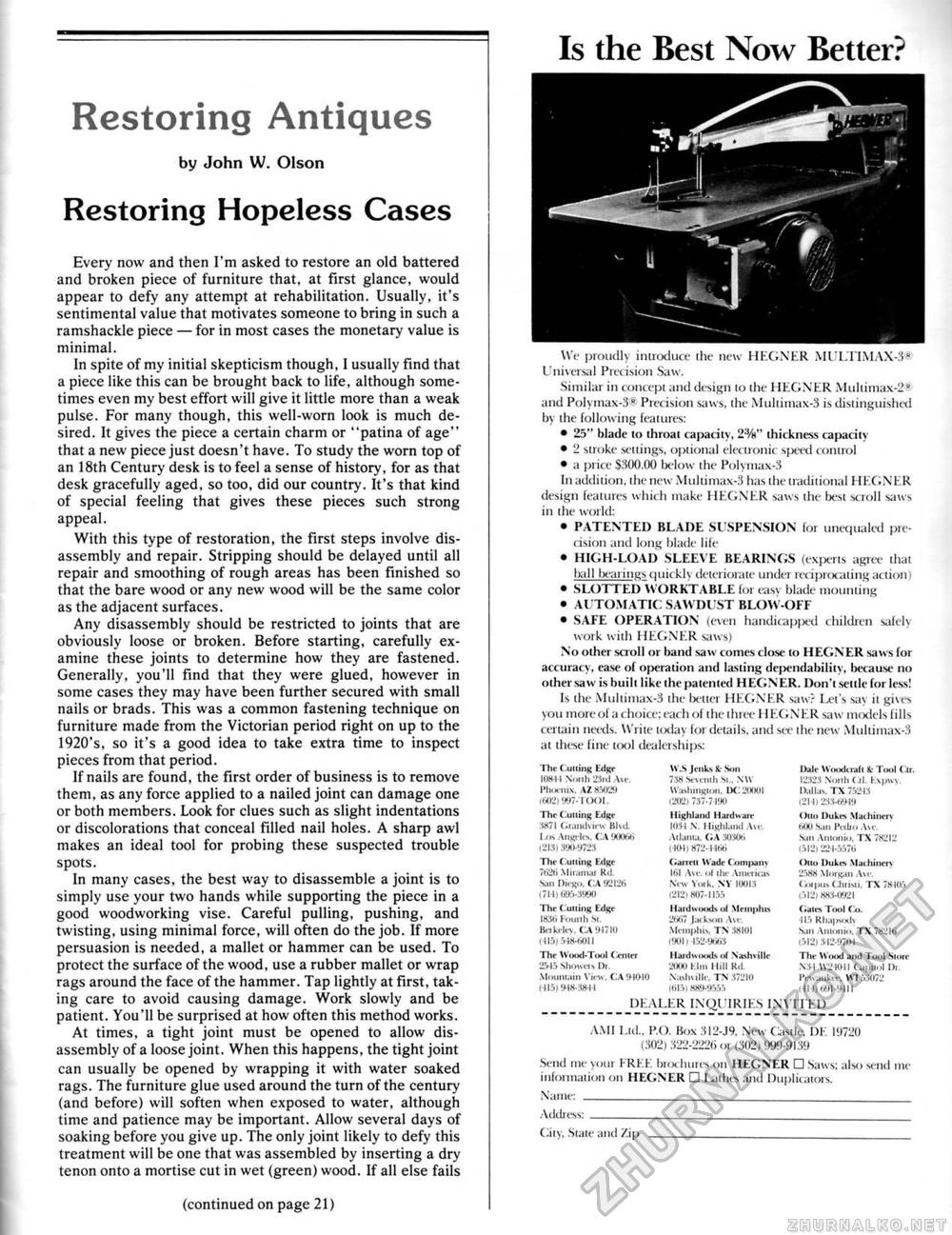

Restoring Antiques by John W. Olson Restoring Hopeless Cases Every now and then I'm asked to restore an old battered and broken piece of furniture that, at first glance, would appear to defy any attempt at rehabilitation. Usually, it's sentimental value that motivates someone to bring in such a ramshackle piece — for in most cases the monetary value is minimal. In spite of my initial skepticism though, 1 usually find that a piece like this can be brought back to life, although sometimes even my best effort will give it little more than a weak puise. For many though, this well-worn look is much desired, It gives the piece a certain charm or "patina of age" that a new piece just doesn't have. To study the worn top of an 18th Century desk is to feel a sense of history, for as that desk gracefully aged, so too, did our country. It's that kind of special feeling that gives these pieces such strong appeal. With this type of restoration, the first steps involve disassembly and repair. Stripping should be delayed until all repair and smoothing of rough areas has been finished so that the bare wood or any new wood will be the same color as the adjacent surfaces. Any disassembly should be restricted to joints that are obviously loose or broken. Before starting, carefully examine these joints to determine how they are fastened. Generally, you'll find that they were glued, however in some cases they may have been further secured with small nails or brads. This was a common fastening technique on furniture made from the Victorian period right on up to the 1920's, so it's a good idea to take extra time to inspect pieces from that period. If nails are found, the first order of business is to remove them, as any force applied to a nailed joint can damage one or both members. Look for clues such as slight indentations or discolorations that conceal filled nail holes. A sharp awl makes an ideal tool for probing these suspected trouble spots. In many cases, the best way to disassemble a joint is to simply use your two hands while supporting the piece in a good woodworking vise. Careful pulling, pushing, and twisting, using minimal force, will often do the job. If more persuasion is needed, a mallet or hammer can be used. To protect the surface of the wood, use a rubber mallet or wrap rags around the face of the hammer. Tap lightly at first, taking care to avoid causing damage. Work slowly and be patient. You'll be surprised at how often this method works. At times, a tight joint must be opened to allow disassembly of a loose joint. When this happens, the tight joint can usually be opened by wrapping it with water soaked rags. The furniture glue used around the turn of the century (and before) will soften when exposed to water, although time and patience may be important. Allow several days of soaking before you give up. The only joint likely to defy this treatment will be one that was assembled by inserting a dry tenon onto a mortise cut in wet (green) wood. If ail else fails Is the Best Now Better? We proudly introduce the new HEGNER MULnMAX-3" Universal Precision Saw. Similar in concept and design to the HEGNER Multimax-2" and Polymax-3» Precision saws, the Multimax-3 is distinguished by the following features: • 25" blade to throat capacity, 2%" thickness capacity • 2 stroke settings, optional electronic speed control • a price S300.00 below the Polymax-3 In addition, the new Multimax-3 has the traditional HEGNER design features which make HEGNER saws tilt* !>e>i scroll saws in the world: • PATENTED BLADE SUSPENSION for unequakd precision and long blade life • HIGH-LOAD SLEEVE BEARINGS (experts agree that ball bearings quit kly deteriorate under reripnxating action • SLOTTED'WORKTABLE lor easy blade mourning • AUTOMATIC SAWDUST BLOW-OFF • SAFE OPERATION {even handicapped children salely work with HEGNER saws) Net other scroll or band saw comes close to HEGN ER saws for accuracy, ease of operation and lasting dependability, because no other saw is built like the patented HEGNER. Don't settle for less! Is the Multimax-S tile ix'ttei HEGNER saw"- l.et's say it gives you more of a c hoice; each oi the three HEGNER saw models lills certain needs. Write today for details, and see the new Multitnax-5 at these fine tool dealerships: The < iitting Edge I tWI I Ninth 23rd An-1'tiwiiix. MWOa (lIKl W-TOOl. The t.iming I ■ i.1 3K71 Grantlvitw Blul, [ jpi Angelis. ca boosli 1219} swmi72s Tin- Culling fridge 762(i Mir-tJivu K i SB!) Oiego. C:a 92136 (714) 693-3990 I In- (lulling tdgr IWtti Foul!11 si, btlla-lrv ( a W7IU (4i5| 548-6011 Thr Wood-Tool Center 2M5 Shoutis IJi Mountain View. ca '.MOIO (list m*-»n W.S Jfiiksfc Sun 7 is Seventh St- \W Washington, IK 20001 1W'im Highland Hardware 1034 N. I highland An Atl.uiu, CA 3030B (4(H) 872-1486 Cairetl Walk- ( ompan) I'll Ave. ol :l>. America* New Vortt, NV 11X113 12! 21 807-1IM Dale Wot nit mil ft Tool (it. !.::lL". Nmth Ol. I \|>w\ IXdlai. TX 75213 (214) 233-09411 Oitu Du Jlci Maehinen itlmi Sail I'edln Am-S.iii Anlimiu, TX 78212 (1121 224-5576 Oitn I luLi-. M,.i IIIIii I'. 2.WS Morgan Axe. ChrtMI. tx VHKI'i I."il2l KK3-1S2I Hanlwoods of MI I |-1 ;!ii- -17 Jackson Ave. Memphis. TN 38101 (901) -152-9663 Hardivuods ot Vashiilk 2000 t lm Kill Kit Naihutte, TV 37210 iril.ii N89.9555 C.au^ Tool <'i. I l.'i R! ti; I-I , i. Sail .......... TX 782H> <5121 SI2-97IH The Wood i nl Tool .Suite \:t-l W2IHH (.ipnoi Dr. PewauJar, W1 >1(172 (4H)B9|.»1II DEALER INQUIRIES INVITED AMI [.tel.. P.O. Box SI2-J9. New Castle, DE 19720 (302) 322-2226 or (302) 999-9139 .Send me your FREE brochures on HEGNER □ Saws; also send me information on HEGNER □ I villus and Duplicators. Name: _ Address: _________ f lily. State and Zip (continued on page 21) |