Woodworker's Journal 1984-8-1, страница 23

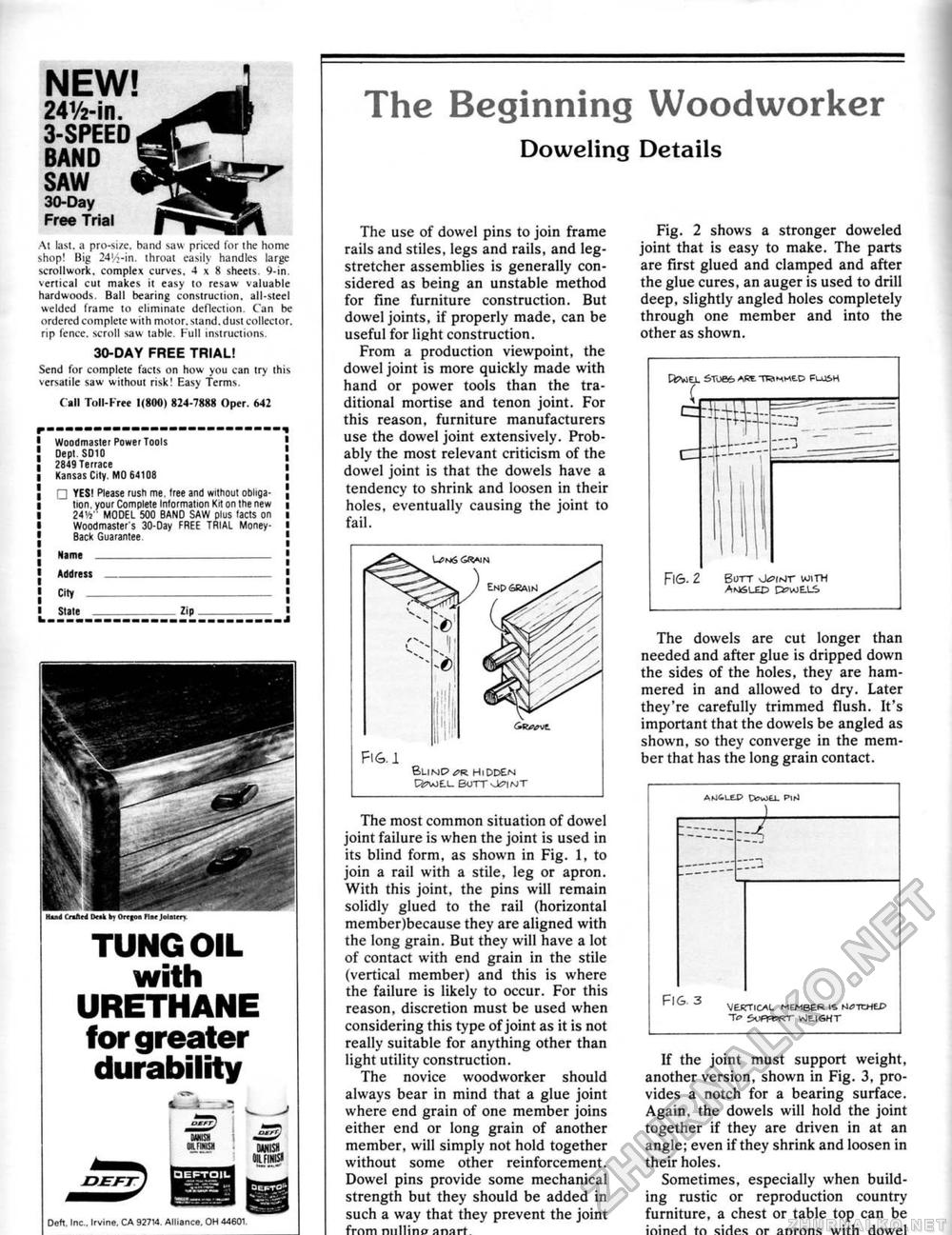

NEW! 24Y2-in. 3-SPEED BAND SAW 30-Day Free Trial At last, a pro-size, band sa« priced fur the home shop! Big 24l/i-in. throat easily handles large scrollwork, com pie* curves, 4x8 sheets. 9-in. vertical cut makes it easy to resaw valuable hardwoods. Ball bearing construction, all-steel welded frame to eliminate deflection. Can be ordered complete with motor, stand, dust collector, rip fence, scroll saw table. Full instructions. 30-DAY FREE TRIAL! Send for complete facts on how you can try this versatile saw without risk! Easy Terms. ( all Toll-Free 1(80*1) 824-78X8 Oper. 641 Woodmasler Power Tools Dept. SD1D 2849 Terrace Kansas City. MO 641 OS □ YES! Please rush me. tree and without obligation, your Complete Information Kit on the new 2AW MODEL 500 BAND SAW plus facts on Wood master's 30-0ay FREE TRIAL Money-Sack Guarantee Name Address City _ Stale _ Zif). d CnJtrd Dnh bi Ortfon FIik Jointm. TUNG OIL with URETHANE for greater durability DANISH OIL fehisi Defi. Inc., Irvine. CA 93714 Alliance, OH 4460V The Beginning Woodworker Doweling Details The use of dowel pins to join frame rails and stiles, legs and rails, and leg-stretcher assemblies is generally considered as being an unstable method for fine furniture construction. But dowei joints, if properly made, can be useful for light construction. From a production viewpoint, the dowel joint is more quickly made with hand or power tools than the traditional mortise and tenon joint. For this reason, furniture manufacturers use the dowel joint extensively. Probably the most relevant criticism of the dowel joint is that the dowels have a tendency to shrink and loosen in their holes, eventually causing the joint to fail. Ft<=>. 1 BUMP <?tz Hidden RSVJE-L BUTT^int The most common situation of dowel joint failure is when the joint is used in its blind form, as shown in Fig, 1. to join a rail with a stile, leg or apron. With this joint, the pins will remain solidly glued to the rail (horizontal member)because they are aligned with the long grain. But they will have a lot of contact with end grain in the stile (vertical member) and this is where the failure is likely to occur. For this reason, discretion must be used when considering this type of joint as it is not realiy suitable for anything other than light utility construction. The novice woodworker should always bear in mind that a glue joint where end grain of one member joins either end or long grain of another member, will simply not hold together without some other reinforcement. Dowel pins provide some mechanical strength but they should be added in such a way that they prevent the joint from ntillino an.irt Fig. 2 shows a stronger doweled joint that is easy to make. The parts are first glued and clamped and after the glue cures, an auger is used to drill deep, slightly angled holes completely through one member and into the other as shown. CfcVltL Sroefe ARE. trimmed Fl-U&H Fie -2 Butt o^nsir win-f AMSLED The dowels are cut longer than needed and after glue is dripped down the sides of the holes, they are hammered in and allowed to dry. Later they're carefully trimmed flush. It's important that the dowels be angled as shown, so they converge in the member that has the long grain contact. Ahl&LEP CfuJEL PI hi Fig. 3 VERTICAL MEMBER 14 MATCHED Te> 5*JfWRT" V0E.ISHT If the joint must support weight, another version, shown in Fig. 3, provides a notch for a bearing surface. Again, the dowels will hold the joint together if they are driven in at an angle; even if they shrink and loosen in their holes. Sometimes, especially when building rustic or reproduction country furniture, a chest or table top can be inined to sides or arirons with dowel |