Woodworker's Journal 1984-8-2, страница 19

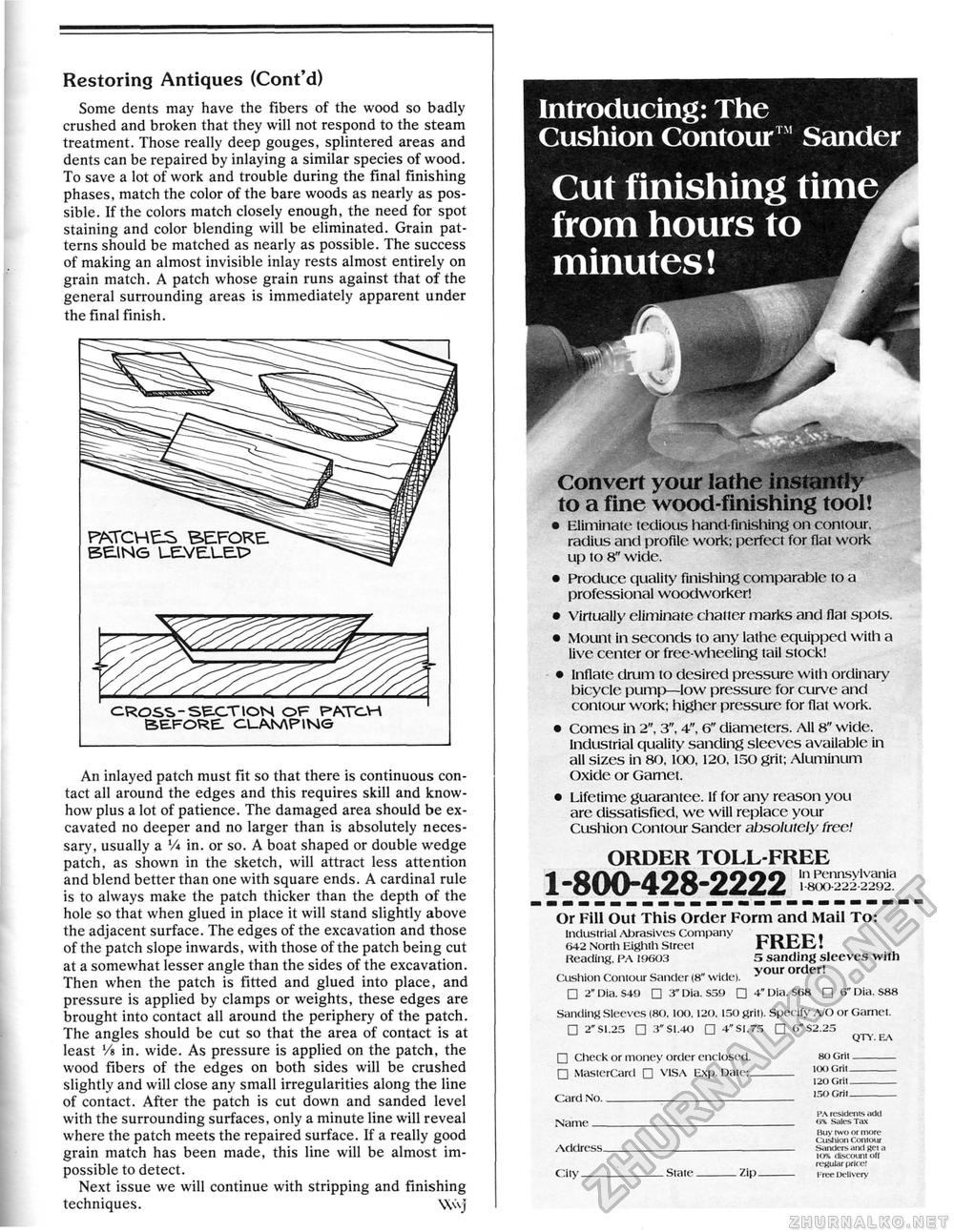

Restoring Antiques (Cont'd) Some dents may have the fibers of the wood so badly crushed and broken that they will not respond to the steam treatment. Those really deep gouges, splintered areas and dents can be repaired by inlaying a similar species of wood. To save a lot of work and trouble during the final finishing phases, match the color of the bare woods as nearly as possible. If the colors match closely enough, the need for spot staining and color blending will be eliminated. Grain patterns should be matched as nearly as possible. The success of making an almost invisible inlay rests almost entirely on grain match. A patch whose grain runs against that of the general surrounding areas is immediately apparent under the final finish. An inlayed patch must fit so that there is continuous contact all around the edges and this requires skill and know-how plus a lot of patience. The damaged area should be excavated no deeper and no larger than is absolutely necessary, usually a % in. or so. A boat shaped or double wedge patch, as shown in the sketch, will attract less attention and blend better than one with square ends. A cardinal rule is to always make the patch thicker than the depth of the hole so that when glued in place it will stand slightly above the adjacent surface. The edges of the excavation and those of the patch slope inwards, with those of the patch being cut at a somewhat lesser angle than the sides of the excavation. Then when the patch is fitted and glued into place, and pressure is applied by clamps or weights, these edges are brought into contact all around the periphery of the patch. The angles should be cut so that the area of contact is at least '/a in. wide. As pressure is applied on the patch, the wood fibers of the edges on both sides will be crushed slightly and will close any small irregularities along the line of contact. After the patch is cut down and sanded level with the surrounding surfaces, only a minute line will reveal where the patch meets the repaired surface. If a really good grain match has been made, this line will be almost impossible to detect. Next issue we will continue with stripping and finishing techniques. W\\j ORDER TOLL-FREE 1-800-428-2222 Or Fill Out This Order Form and Mail To: Industrial Abrasives Company u r? | 642 North Eighth Street Jr KcL J Reading, pa I9603 5 sanding sleeves with ,. - „ ■, . your order! Cushion Contour Sander <8 wide). □ 2" Dia. $49 □ 3" Dia. S39 □ 4" Dia. SfiH □ 6" Dla. SS8 Sanding Sleeves |8(), loo. 120.150 grin. Specify A/O or Garnet. □ 2* SI.25 □ 3" SI,4t) □ SI.75 □ 6" S2.2S □ Check or money order enclosed □ MasterCard □ VISA Exp. Date:, Card No.. Name. Address- City. _ State. . Zip. QTY. EA 80 Gril___„ )<x> Grit___ 120 Gril.--- ISO Grit--- PA residents ijclcj t >*. sales Tax Iki, two or nKine cushion Contour Sandejs antt a Krtt <HS£'ount oil rcj4u lur price! Free Delivery Introducing: The Cushion Contour ™ Sander Cut finishing time from hours to minutes! Convert your lathe instantly to a fine wood-finishing tool! • Eliminate tedious hand-finishing on contour, radius and profile work; perfect for flat work up to 8" wide. • Produce quality finishing comparable to a professional woodworker! • Virtually eliminate chatter marks and flat spots. • Mount in seconds to any lathe equipped with a live center or free-wheeling tail stock! • Inflate drum to desired pressure with ordinary bicycle pump—low pressure for curve and contour work; higher pressure for flat work. • Comes in 2", 3", 4", 6" diameters. All 8" wide, industrial quality sanding sleeves available in all sizes in 80, 100,120, ISO grit; Aluminum Oxide or Garnet. • Lifetime guarantee. If for any reason you are dissatisfied, we will replace your Cushion Contour Sander absolutely free! |