Woodworker's Journal 1984-8-2, страница 20

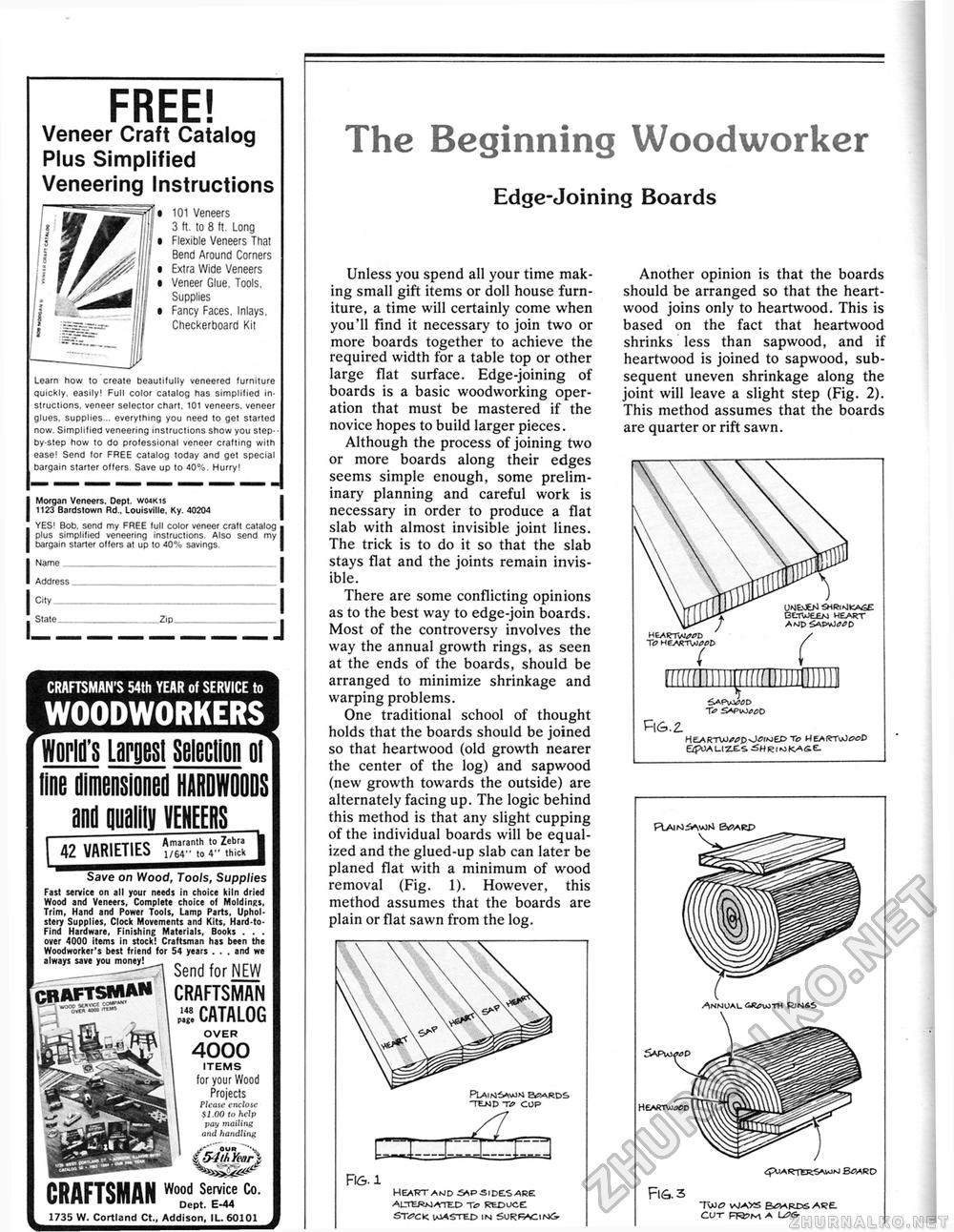

FREE! Veneer Craft Catalog Plus Simplified Veneering Instructions • 101 Veneers 3 ft. to 8 ft. Long • Flexible Veneers That Bend Around Corners • Extra Wide Veneers • Veneer Glue. Tools. Supplies t Fancy Faces. Inlays, Checkerboard Kit Learn how to create beautifully veneered furniture quickly, easily! Full color catalog has simplified in-structions. veneer selector chart. 101 veneers, veneer glues, supplies... everything you need to get started now. Simplified veneering instructions show you step-by-step how to do professional veneer crafting with ease! Send for FREE catalog today and get special bargain starter offers. Save up to 40%. Hurry! Morgan Veneers. Dept. wmms 1123 Bardstown Rd„ Louisville. Ky. 40204 YES! Bob. send my FREE full color veneer craft catalog ■ plus simplified veneering instructions. Also send my I bargain starter offers at up to 40% savings. Name _______ ________ City _ State. _Zip. CRAFTSMAN'S 54th YEAR of SERVICE to WOODWORKERS World's Largest Selection ol line dimensioned HARDWOODS and Quality VENEERS l 42 VARIETIES | Save on Wood, Tools, Supplies Fast service on all your needs in choice kiln dried Wood and Veneers, Complete choice ol Moldings, Trim, Hand and Power Tools, Lamp Parts, Upholstery Supplies, Clock Movements and Kits, Hard-to-Find Hardware, Finishing Materials, Books . . . over 4000 items in stock! Craftsman has been the Woodworker's best friend for 54 years . . . and we always save you money! craftsman Send for NEW CRAFTSMAN Z CATALOG OVER 4000 ITEMS for your Wood Projects Please enclose $1.00 to help pay mailing and handling OUR £5-1 Kurt CRAFTSMAN wtPtSe™e00 1735 W. Cortland Ct„ Addison, 1L. 60101 The Beginning Woodworker Edge-Joining Boards Unless you spend all your time making small gift items or doll house furniture, a time will certainly come when you'll find it necessary to join two or more boards together to achieve the required width for a table top or other large flat surface. Edge-joining of boards is a basic woodworking operation that must be mastered if the novice hopes to build larger pieces. Although the process of joining two or more boards along their edges seems simple enough, some preliminary planning and careful work is necessary in order to produce a flat slab with almost invisible joint lines. The trick is to do it so that the slab stays flat and the joints remain invisible. There are some conflicting opinions as to the best way to edge-join boards. Most of the controversy involves the way the annual growth rings, as seen at the ends of the boards, should be arranged to minimize shrinkage and warping problems. One traditional school of thought holds that the boards should be joined so that heartwood (old growth nearer the center of the log) and sapwood (new growth towards the outside) are alternately facing up. The logic behind this method is that any slight cupping of the individual boards will be equalized and the glued-up slab can later be planed flat with a minimum of wood removal (Fig. 1). However, this method assumes that the boards are plain or flat sawn from the log. Heart awd ^apsides/Are ALrrERMATCD To REDUCE ST0CK WASTED IN SURf=*C.IN&- Another opinion is that the boards should be arranged so that the heart-wood joins only to heartwood. This is based on the fact that heartwood shrinks less than sapwood, and if heartwood is joined to sapwood, subsequent uneven shrinkage along the joint will leave a slight step (Fig. 2). This method assumes that the boards are quarter or rift sawn. T<s> Sapmco R6.2. H£ARTU)«>DOtflME£> To HEARTuJoeC EipOAUZXS ^HRIWMSE. Safwod Heartvwod FI6.3 ^pUARTBESAWM BOAKD TW0C> WA>S &SWRC6ARE. CUT FF&hA A |